Why does my Miller Copilot display a welder communication error?

- JJennifer HolmesAug 7, 2025

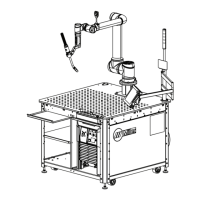

A welder communication error indicates a communication issue between the cobot and the welder. To resolve this, cycle the system power at the disconnect located on the back side of the system.