OM-291865 Page 36

SECTION 10 – TROUBLESHOOTING

This troubleshooting list addresses only potential system problems and does not cover the cobot error and alarm codes. For a comprehensive

list of cobot errors see the cobot operations manual.

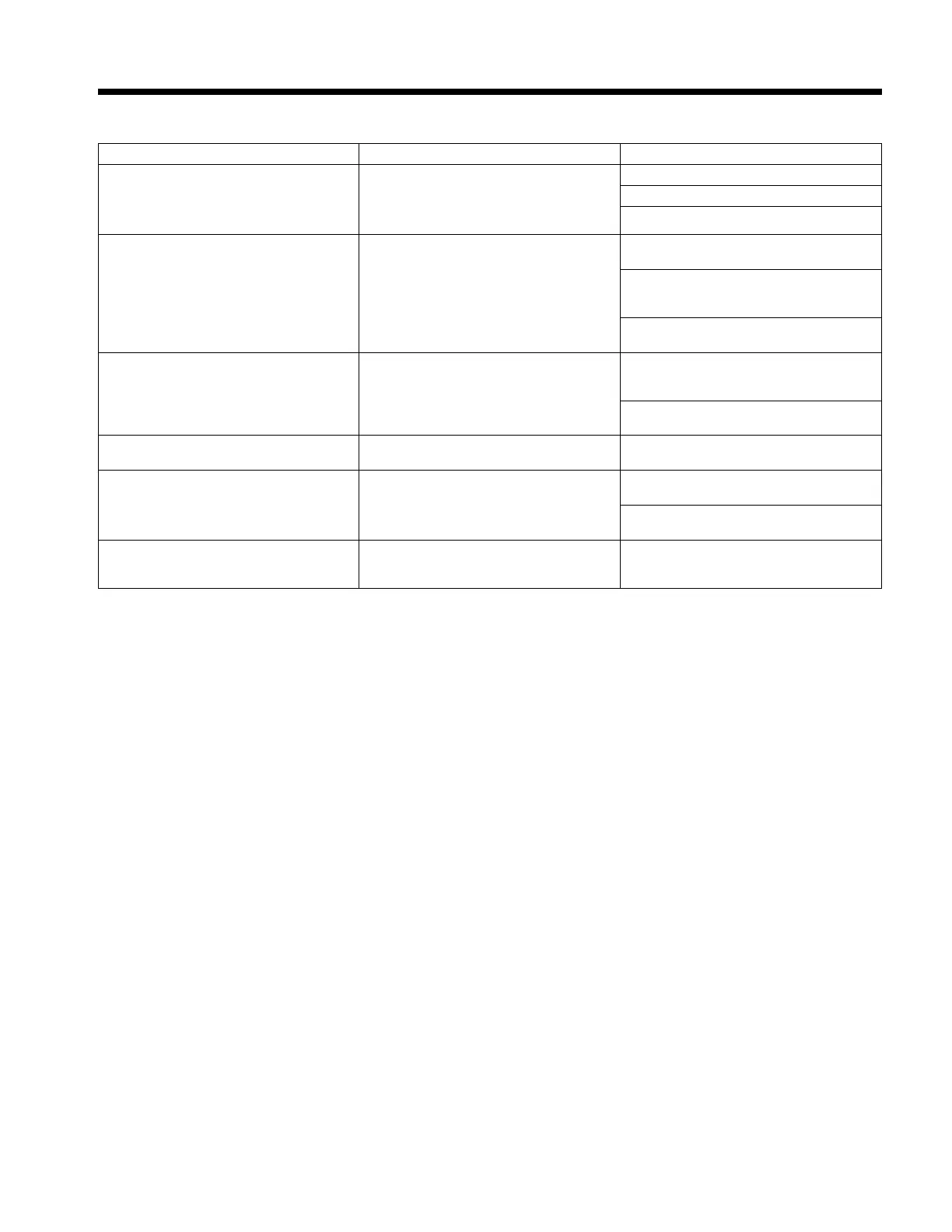

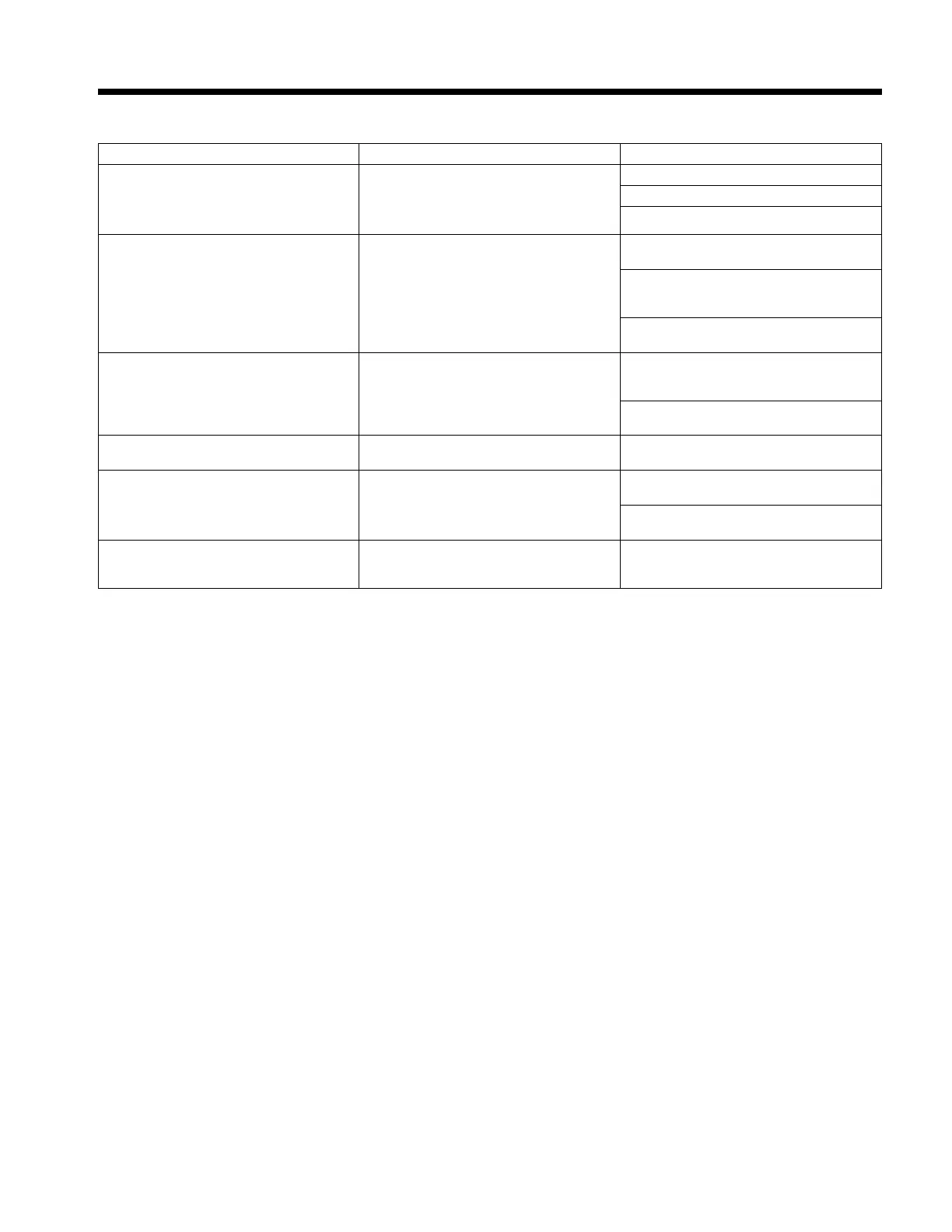

Problem Probable Cause Remedy

No drive power .

Emergency Stop Error displayed on pendant.

Solid red light.

Operation ESTOP, Pendant Estop was

activated.

Check both E-Stop switches for activation.

Check Teach Pendant cable.

Check Operation Box cable.

Red light flashing. Free Drive Grip Error or Cobot internal error. Release free-drive enable switch and wait for

flashing red light to turn off.

Clear error on pendant. If error does not pop

back up, then wait for red light to turn off for

about one minute.

If error does not clear, cycle power on the

cobot.

Cobot does not turn on. 120V cord not plugged into wall outlet or wall

outlet has no power.

Check to see if 120V cord coming from cobot

system main disconnect is plugged into wall

outlet receptacle.

Have qualified personnel check to see if 120

VAC is available at wall outlet.

Cobot does not weld. Weld Enable switch on Operation Box is set

to Off.

Set Weld Enable switch to On.

Welder does not turn on. Customer supplied disconnect is switched to

off or fuses are blown.

Check to see if customer supplied disconnect

is in ON position.

Have qualified personnel check to see if cus-

tomer supplied disconnect has blown fuses.

Cobot displays welder communication error

or can’t feed wire or purge gas from teach

pendant.

Communication error between cobot and

welder.

Cycle system power at disconnect located on

back side of system (see Section 8-1).

Loading...

Loading...