OM-291865 Page 21

5-3. Leveling The System

Raising Leveling Mounts

Lowering Leveling Mounts

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

OM-222 Page 1

NGO’s

tools/

trashcan continuitytester

Grinder left

PAPR

level

Drum

IGBT tester

Respirator

tape measure

scraper

crow-foot wrench

greenlee knockout

punch

gear puller

Phillips #2 bit

Wo

oden Wedge

Grinding Wheel

Dressing Tool

Safety

shoe

Hard hat

Shop A

pron

Ch

op Saw

Oxy-Fuel Goggle

Acetylene Tank Wrench

Kevlar sleeve Sealing tape

Wrench socket

Spanner wrench

Lifting Strap

Torx socket

center punch

rag

Right Angle Screwdriver

Dr

ill with socket

Drift pin

Grinder right

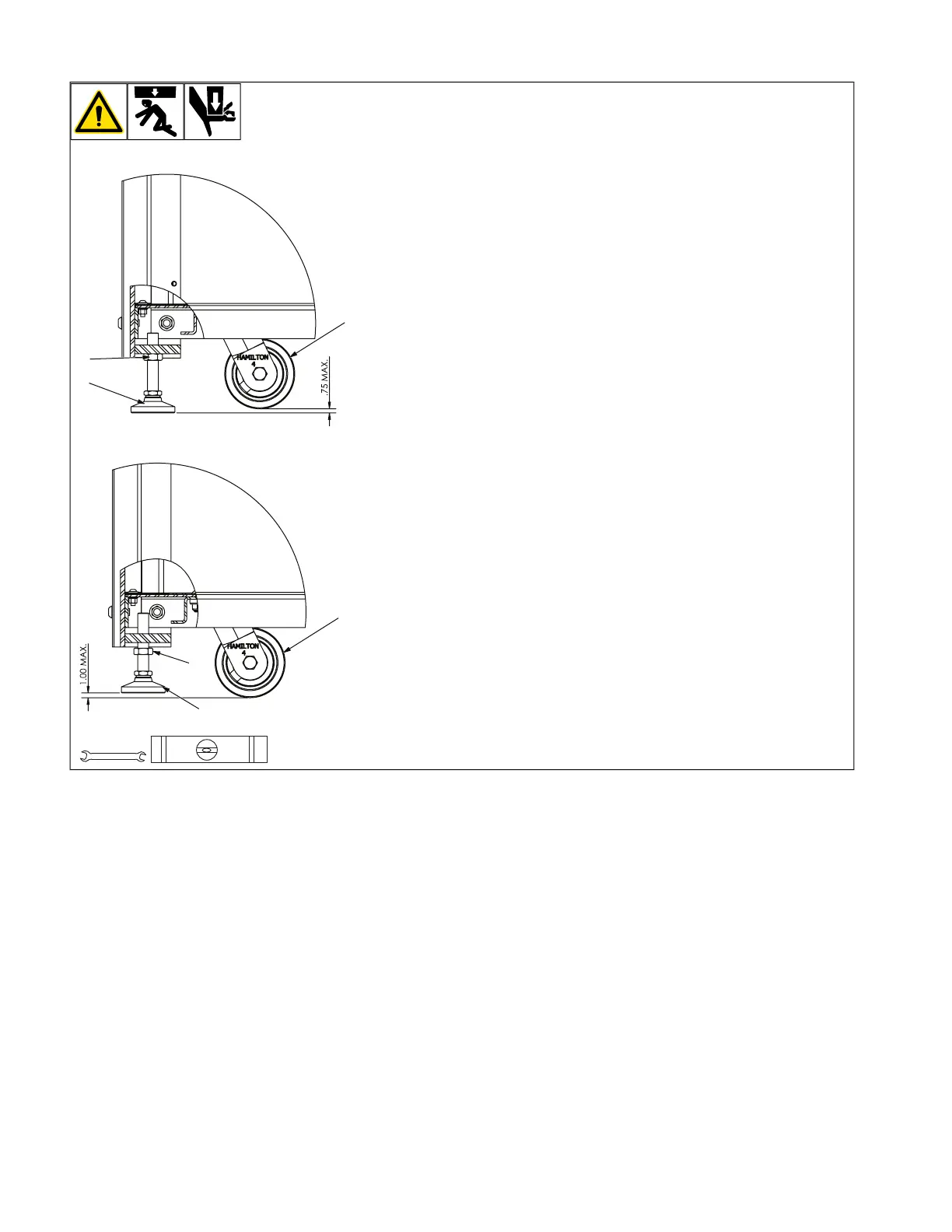

1 Leveling Mount

2 5/8 in. (16 mm) Jam Nut

3 Wheel

Leveling the system is recommended.

Lowering Leveling Mounts For Welding

Operation

Spin leveling mount down until it contacts

the floor.

Using wrench, continue to spin the leveling

mount until cart is raised off the wheels. Do

not raise wheels by more than 0.75 in. (19

mm).

Repeat on all four corners. Check the table

level and adjust as required to level table.

Use wrench to secure 5/8 in. jam nuts.

NOTICE – Cart must be supported by level-

ing mounts to support rated load of 1500 lb

(680 kg).

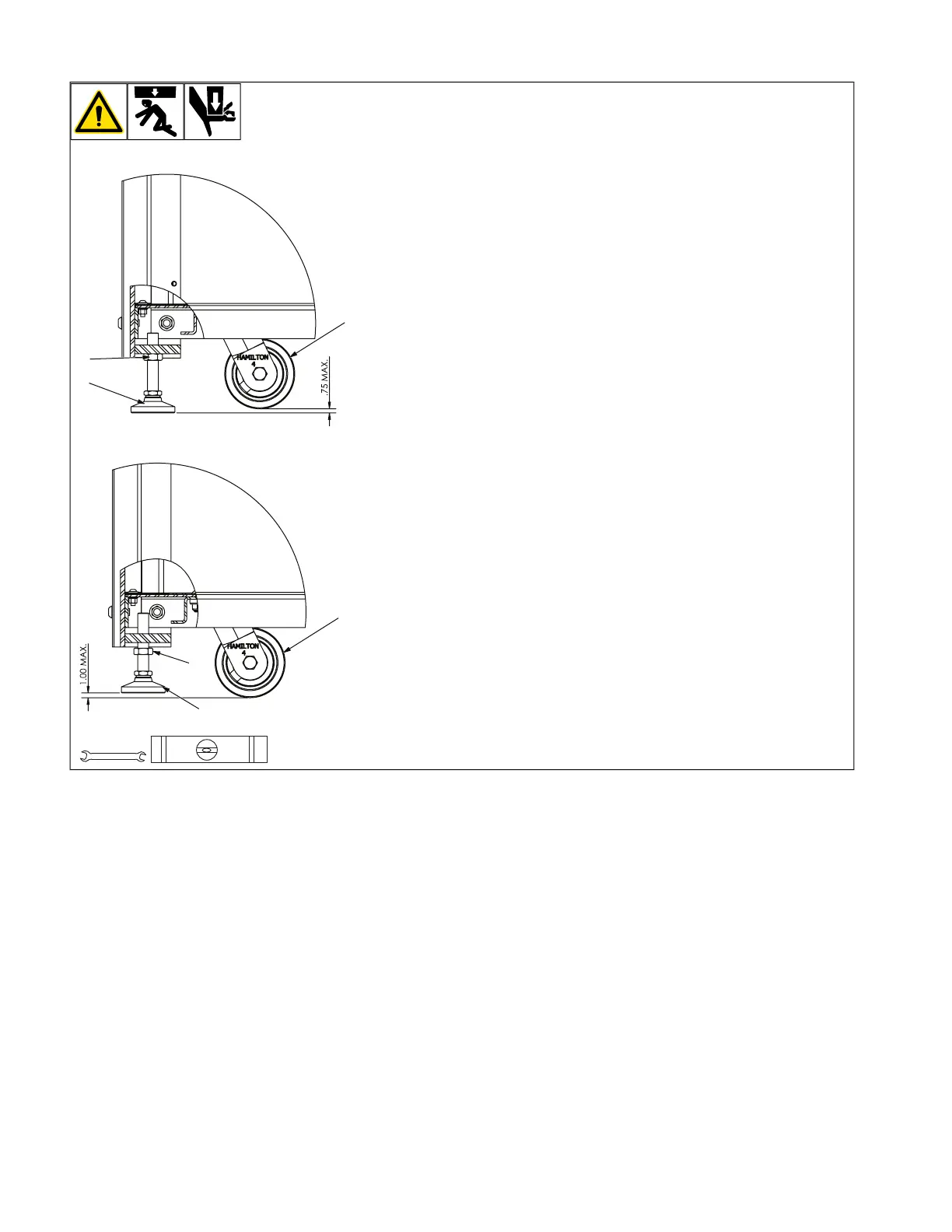

Raising Leveling Mounts For Transit

Remove tooling from cart before transit.

Maximum transit load is 750 lb (340 kg).

Loosen 5/8 in. jam nut enough to allow rais-

ing of leveling mount.

Spin leveling mount to raise it off the floor by

at least 1/4 in. (6 mm). Do not raise mounts

past 1 inch (25 mm).

Repeat on all four corners.

Loading...

Loading...