OM-291865 Page 34

8-4. Inputs And Outputs

Cobot inputs and outputs are used to operate the system and understanding where to view these and what they mean can make running and

troubleshooting the system much easier.

To view the inputs and outputs go to Settings/IO Tab.

A. Cobot Inputs

Input signals from the different buttons and safety devices let the cobot know what operation to perform, and when it is safe for the cobot to start

moving. The following list covers the basic inputs to the cobot.

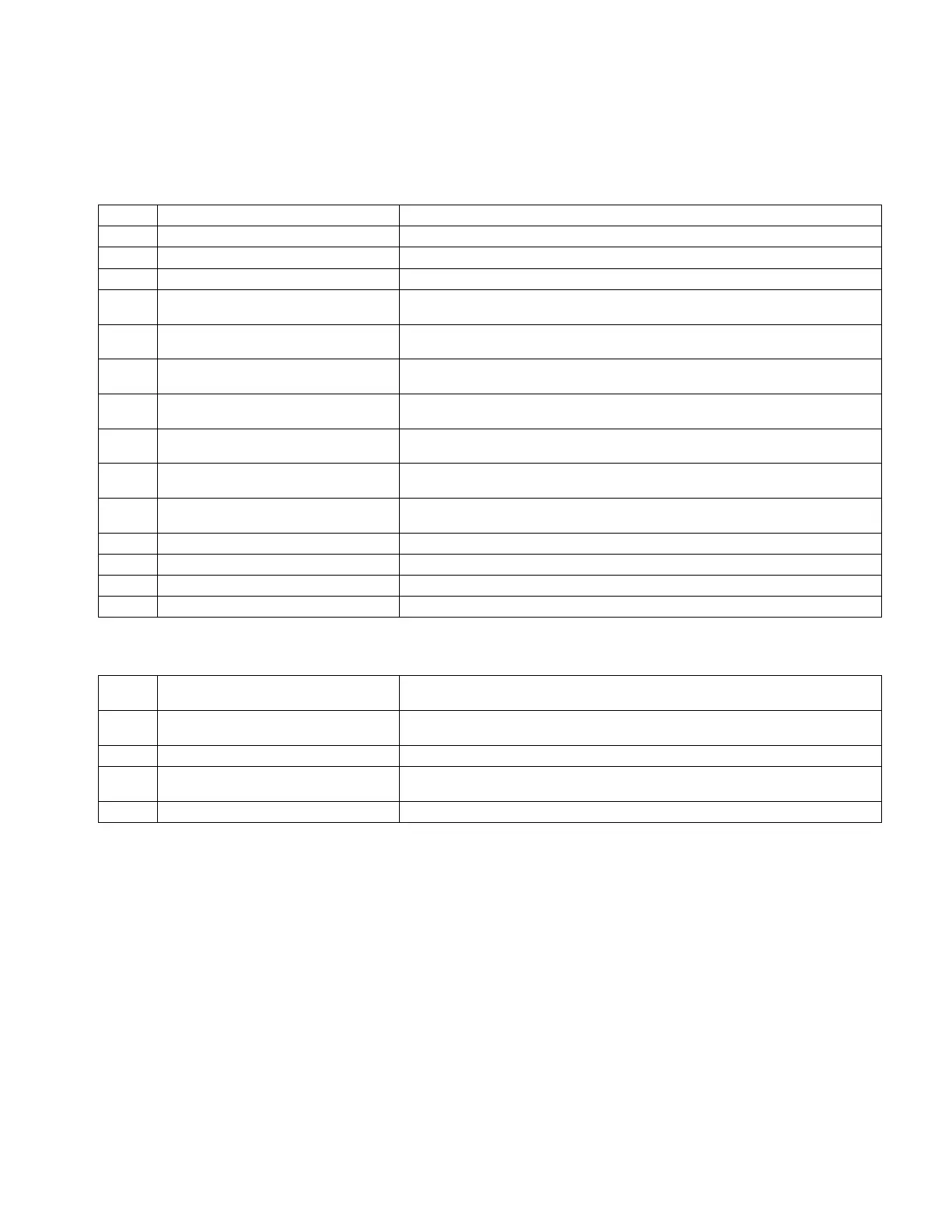

Input # Name Description

DI00 Auto Auto Mode Input. Changes operational mode to Auto

DI01 Teach Teach Mode Input. Changes operational mode to Teach

DI02 Start/Pause When cobot is in Auto Mode, Start/Pause Inputs Starts and Pauses Active Program

DI03 End Program When cobot is in Auto Mode End Program Stops cobot at current position and ends

Active program

DI04 Position Store When cobot is in teach Mode, Puck mounted Position Store Button adds non-weld po-

sition points.

DI05 Weld Store When cobot is in teach Mode, Puck mounted Weld Store Button adds weld position

points.

DI06 Linear/Circular When cobot is in teach Mode, Puck mounted Linear/Circular Button toggles weld posi-

tion points between linear and circular.

DI07 Weld Enable/Disable When Weld Enable/Disable Switch is set to Enable, Welding commands are valid.

When Switch is set to disable, welding commands are invalid.

DI10 Wire Jog Fwd When wire jog fwd input is valid weld wire is feed forward. If input is held valid for 3 sec

wire will jog forward at high speed.

DI11 Wire Jog Rev When the wire jog rev input is valid weld wire will retract. If input is held valid for 3 se

wire will retract at high speed.

SI00 Emergency Stop input CH1 External Emergency Stop Input (At Operator Station) CH1

SI01 Emergency Stop input CH2 External Emergency Stop Input (At Operator Station) CH2

SI06 Force Enable CH1 Lead Through Teach Enable Switch (Located at torch puck) CH1

SI16 Force Enable CH2 Lead Through Teach Enable Switch (Located at torch puck) CH2

B. Cobot Outputs

Cobot outputs tell the cobot when to run a tip change and let the system know when the cobot is clear of the work and at the home position.

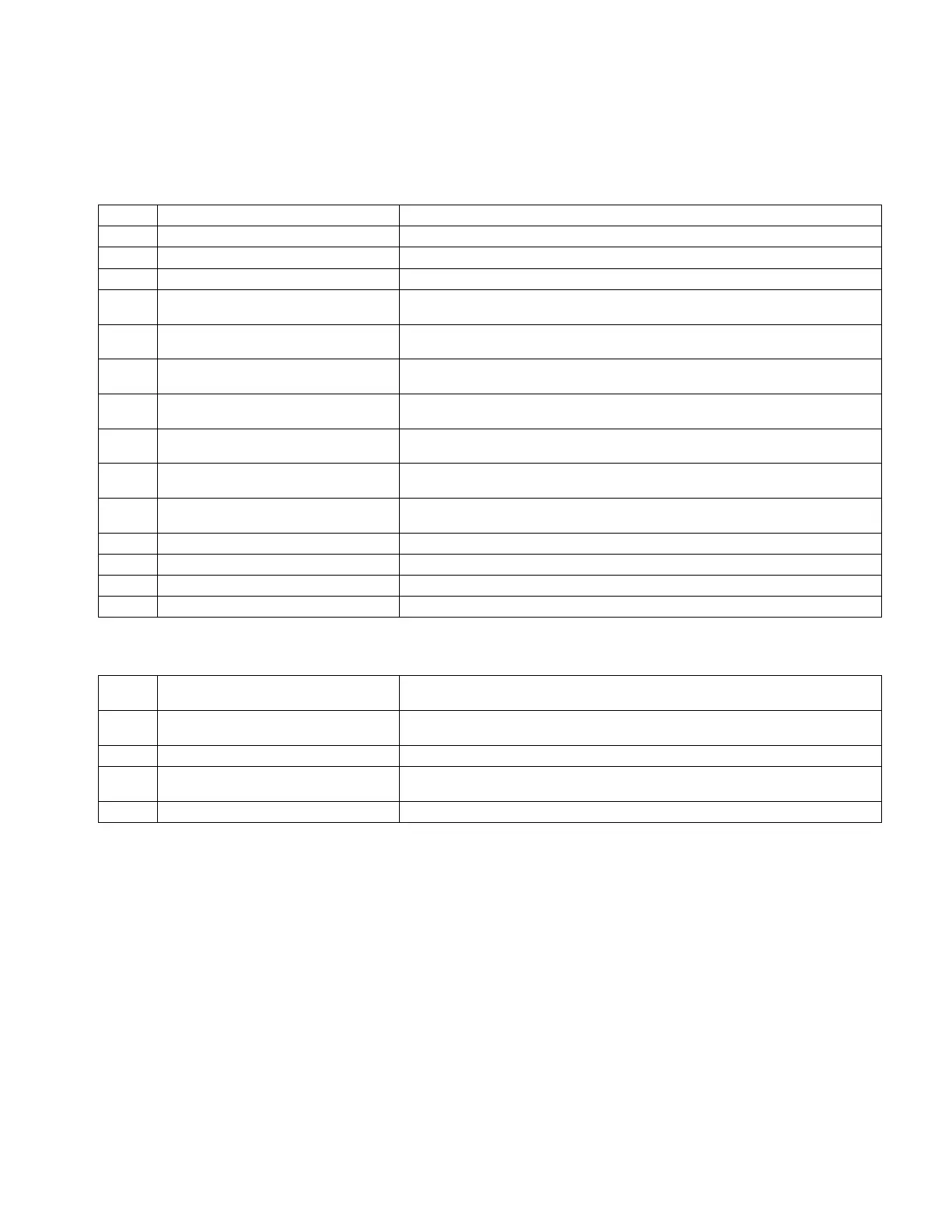

Output

#

Name Description

DO00 Cobot Moving/Welding Output is valid without flashing when cobot is moving. Output is valid and flashing

when the cobot is welding (Amber)

DO01 Auto Mode Output is valid when cobot is in auto mode (Blue)

DO02 E-Stop/Error State Output is valid without flashing when cobot is in e-stop. Output is flashing when cobot

is in error state

DO03 Collaborative Mode Output is valid when cobot is in collaborative mode

8-5. Auto Mode Start-Up

Once the weld programs have been created, follow the steps below to run the cobot automatically.

Option 1: Running the program Active in Teach

Step 1. Turn the operation box Auto/Teach key switch to Auto.

Step 2. Load and secure the part for welding.

Step 3. If cobot is not at first point in active program, Press and hold start button until cobot is at first point. Releasing button prior to reaching first

point will stop cobot.

Step 4. In case something is in the way of the cobot while moving to first position of program, switch Auto/Teach switch to teach and hand guide

cobot around obstacle and then switch back to Auto.

Step 5. Once cobot has reached first point in program. Press the START/PAUSE push button once. This will start the program.

Step 6. Pressing the start/pause button while the cobot is running the active program will cause the cobot to pause.

Step 7. Pressing the Start/Pause after the cobot has paused will resume the active program at the point it paused.

Step 8. Pressing the end program button while the cobot is running the active program will cause the cobot to stop and end the active program

Step 9. Pressing e-stop (or if the cobot generates an error while running the active program) will cause the cobot to stop and end the active

program.

Loading...

Loading...