OM-291865 Page 26

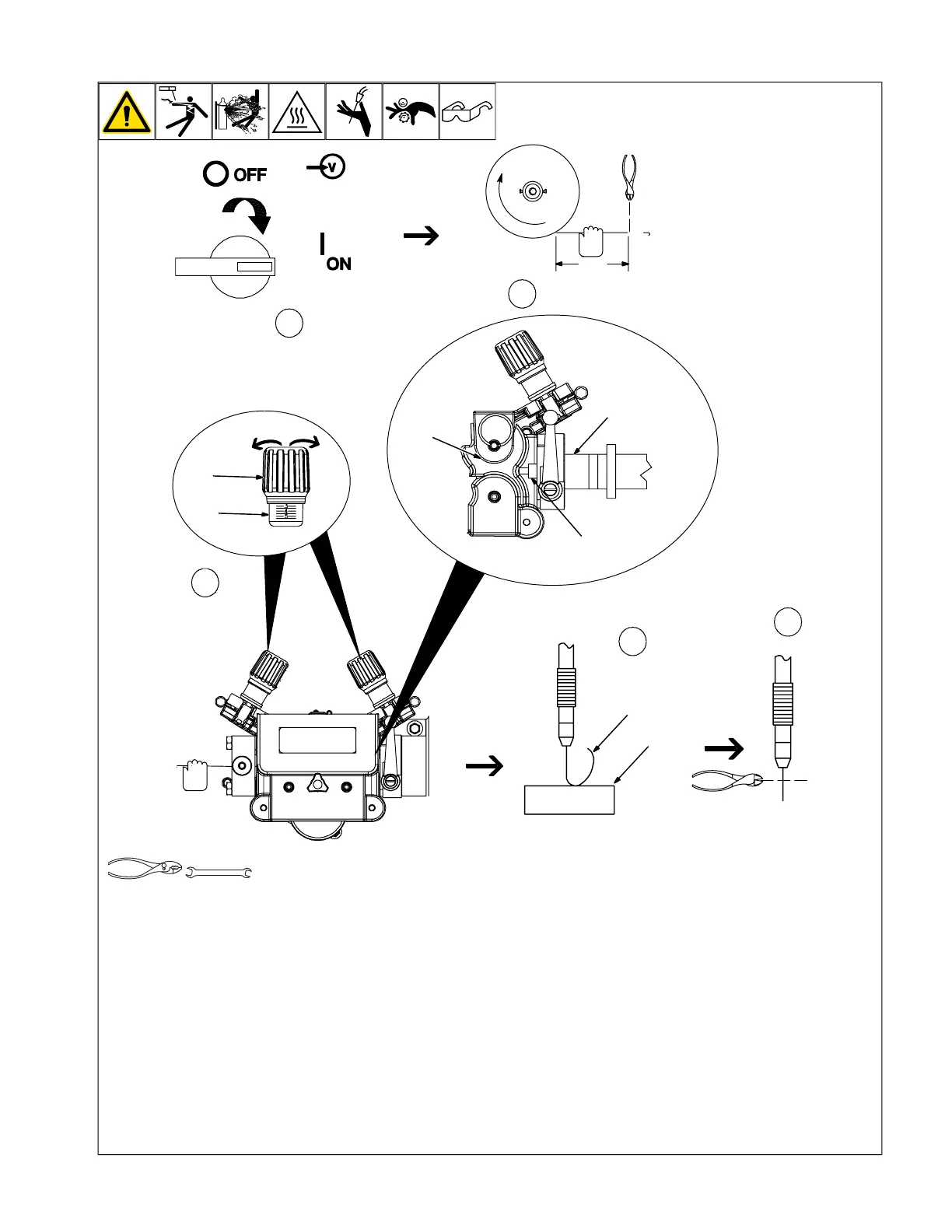

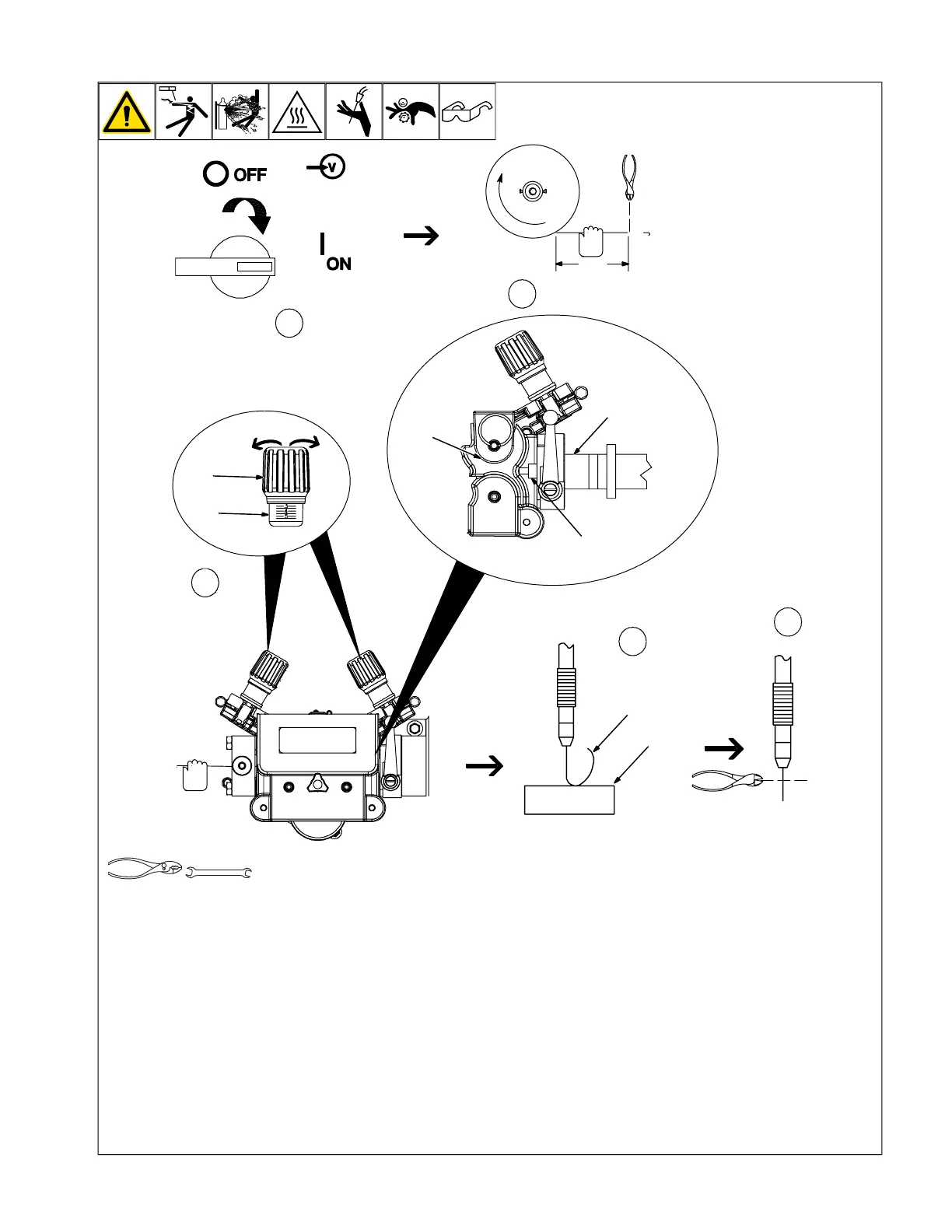

5-8. Installing And Threading Welding Wire

6 in.

(150 mm)

WOOD

3

1

2

3

4

5

6

7

2

1

4

5

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

OM-222 Page 1

allen_wrench

NGO’s

tools/

flathead philips head wrench

pliers

knife

heavy-duty workclamp light-duty workclamp wirecutter frontcutter

allen_set

needlenose

steelbrush nutdriver

chippinghammer

solderiron

stripcrimp

drill

torque wrench

socket wrench

hammer awl file

crimper

paintbrush

feelergauge flashlight ruler

toothbrush

greasegun

qtip (swab)

vicegrip

handream

punch

filterwrench

strapwrench

airgun

solvent pinextractor eprompuller pipewrench

torque screwdriver

crescent wrench

15/16 in.

F

Verify correct drive rolls are installed.

1 Example Of No Wire Slippage

2 Nonconducting Surface

3 Pressure Adjust Knob

4 Pressure Indicator Scale

5 Drive Rolls

6 Back Of Gun

7 End Of Liner

Step 1. Turn power switch to “ON” position,

located on front of power source.

Step 2. Pull and hold wire. Cut off end of

wire.

F

Hold wire tightly to keep it from

unraveling.

Step 3. Push wire through guides up to drive

rolls; continue to hold wire.

Install gun. Lay gun cable out straight. Cut

off end of wire. Push wire through guides up

to drive rolls; continue to hold wire. Press

Jog button to feed wire out gun.

F

For best wire feeding performance, be

sure that the outlet cable has the prop-

er size liner for the welding wire size

being used. Also, when the gun is in-

stalled, the liner extending from the

back of the gun should be as close to

the drive rolls as possible, without

touching.

Step 4. To adjust drive roll pressure, begin

by holding nozzle about 2 in. (51 mm) from

nonconducting surface and pressing gun

trigger to feed wire against surface.

Step 5. Cut wire off.

F

For soft wire or small diameter stain-

less steel wire, reduce drive roll pres-

sure on the rear roll to half that of the

front rolls.

Loading...

Loading...