OM-253893 Page 13

SECTION 5 − CONNECTIONS

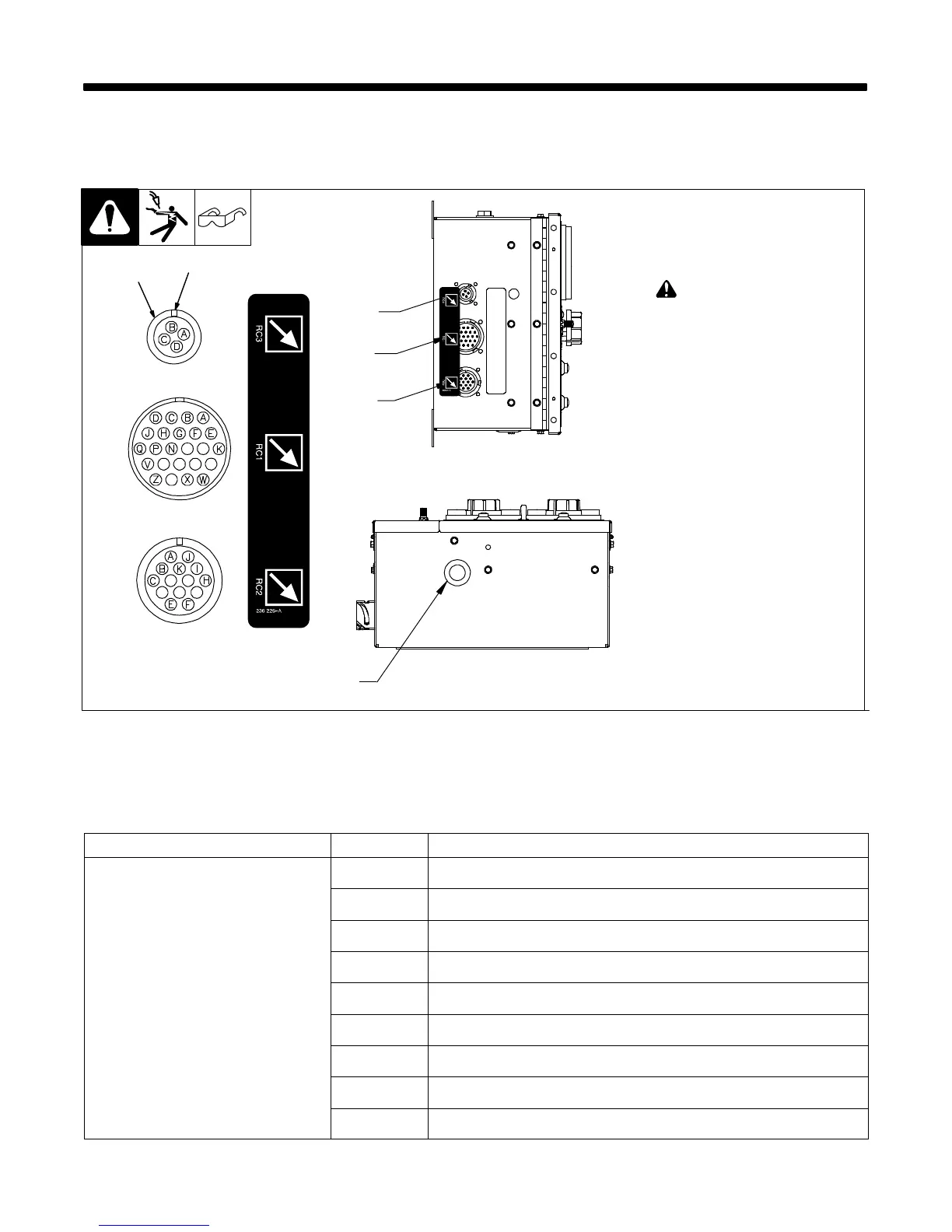

5-1. Left Side Panel Connections

263203-A

1

2

1 Receptacle

2 Keyway

3 Access Holes - For Customer

Use: Connections To Terminal

Strips.

! Turn Off welding power

source and weld control and

disconnect input power be-

fore opening access door.

Install strain relief (customer

supplied) in access hole.

Route incoming cables through

user access hole prior to making

connections to internal terminal

blocks.

4 Receptacle RC3:

Connection To Flux Hopper.

5 Receptacle RC1: Connection

To Welding Power Source.

6 Receptacle RC2: Connection

to Wire Drive Motor

To connect matching interconnect-

ing cord to one of the above

receptacles, align keyway, insert

plug, and tighten twist lock collar.

Connect remaining end of cord to

matching receptacle on applicable

equipment.

3

Bottom

4

5

6

Left Panel

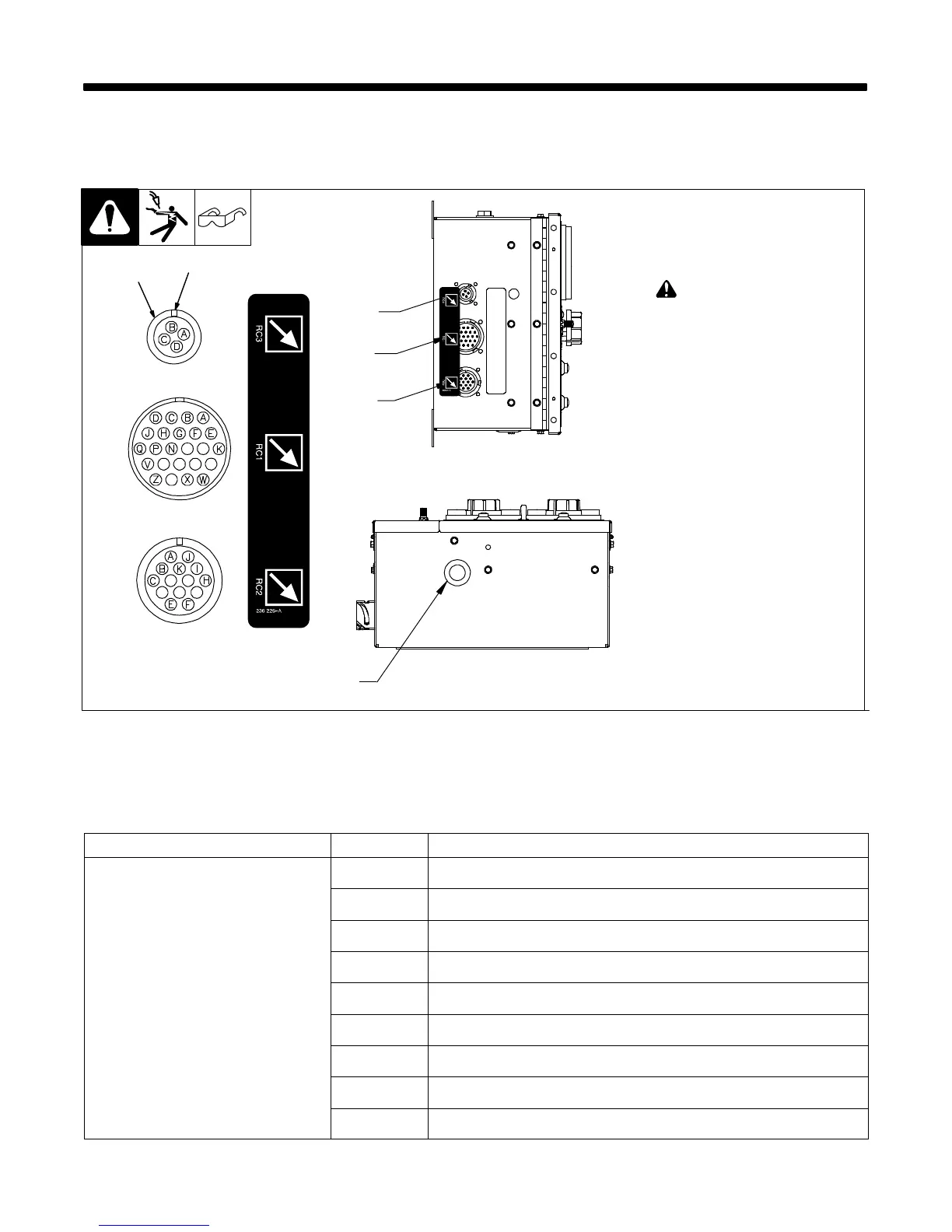

5-2. Receptacle RC2 Information

Socket Socket Information

Wire Drive Hookups

J Positive (+) motor armature (38 VDC motor).

A Negative (−) motor armature (38 VDC motor).

H Motor identification (resistor across H and B).

C Shield drain leads.

I Encoder VCC (+5 VDC).

K Encoder channel A.

B Encoder common and motor identification (resistor across H and B).

E Reserved for negative volt sense lead

F Positive volt sense lead

Loading...

Loading...