ABOUT THE AIRANGER XPL PLUS

The AirRanger XPL+ is to be used only in the manner outlined in this instruction manual.

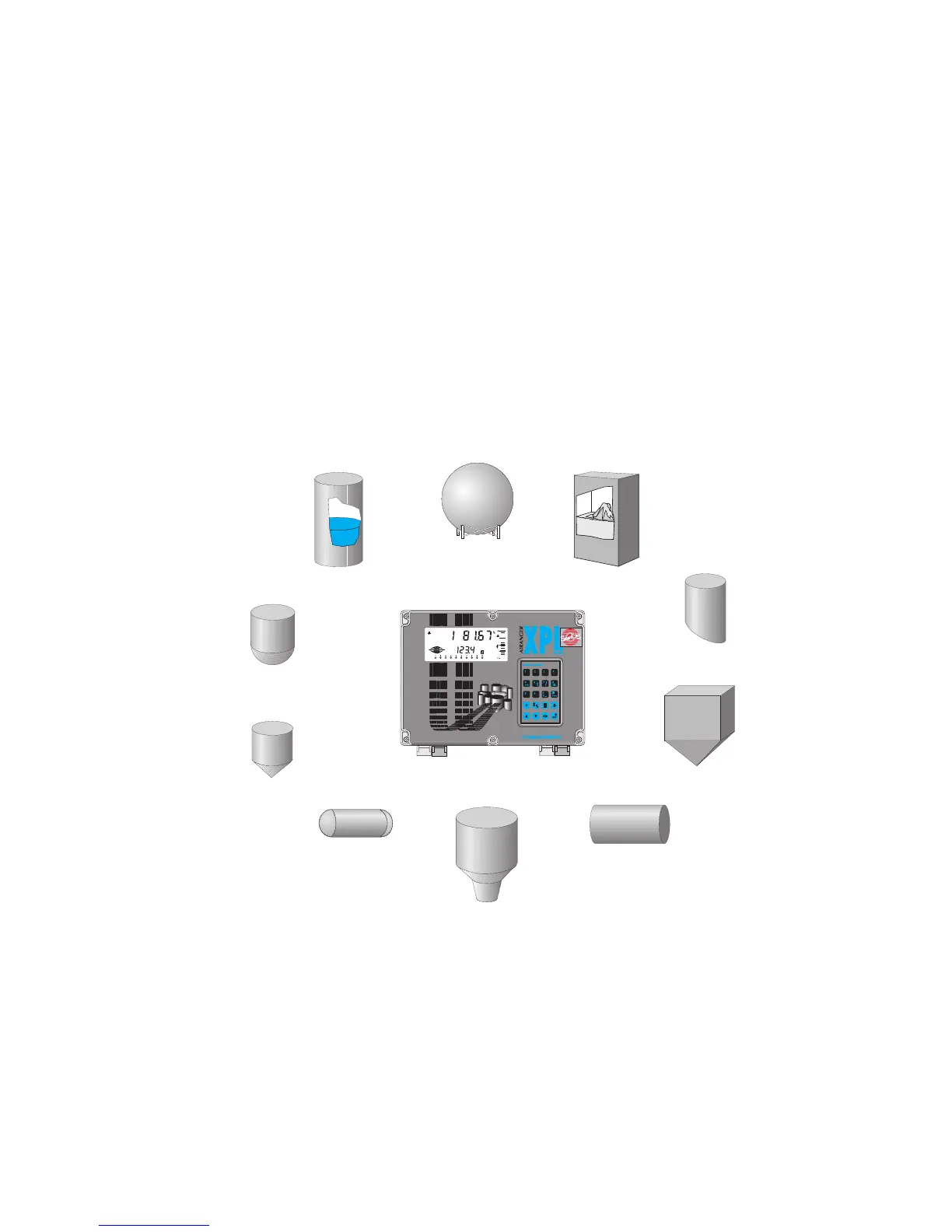

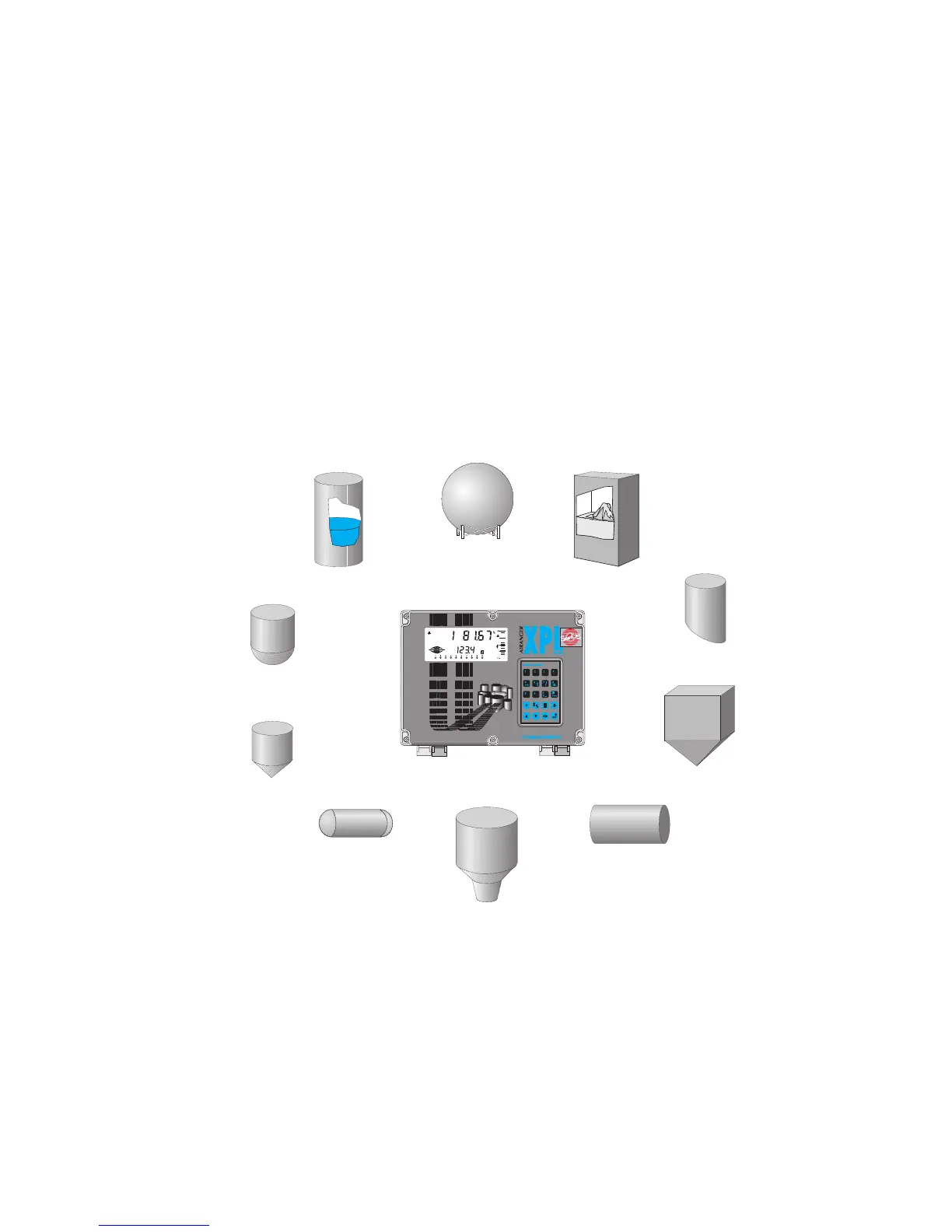

The XPL+ is a microprocessor based level monitor designed specifically for bulk solids and liquid level

measurement applications. An XPL+ level monitor, utilizing a single Milltronics ultrasonic transducer,

accurately monitors vessel material level without material contact. By using an additional transducer for

each vessel, the XPL+ can monitor the material level in up to 10 vessels.

The XPL+ transmits electronic pulses to each scanned ultrasonic transducer. The transducer converts the

electronic pulses to ultrasonic pulses which are emitted from the transducer face in a narrow beam. The

XPL+ measures the time from the pulse emission, to receiving the reflection (echo) from the material. Using

the time measured, the XPL+ calculates the distance from the transducer face to the material.

The distance calculation is dependent upon the sound velocity within the vessel. When Milltronics

ultrasonic/temperature transducers are used, variable air temperatures are independently compensated for

each vessel. For superior air temperature compensation, a TIB-9 card may be used with individual Milltronics

TS-3 temperature sensors for each vessel. A simple calibration feature compensates for

homogeneous

(consistent composition) atmospheres other than air.

The XPL+ is capable of monitoring wheat in 60 m (200 ft) high silos, acetone in 45 gallon barrels, or almost

anything in between, in any combination. (Ensure the transducer selected for each vessel suits the material

and measurement range required).

This material and measurement range versatility is accomplished by utilizing Milltronics patented Sonic

Intelligence

TM

. Sonic Intelligence provides high measurement reliability, regardless of changing conditions

within the vessel monitored.

By utilizing ultrasonic echo ranging principles with Sonic Intelligence and velocity compensation, the XPL+

provides outstanding measurement accuracy, usually within 0.25% of range.

PL-532 6

Loading...

Loading...