616

6. PROTECTIVE FUNCTIONS

6.6 Check first when you have a trouble

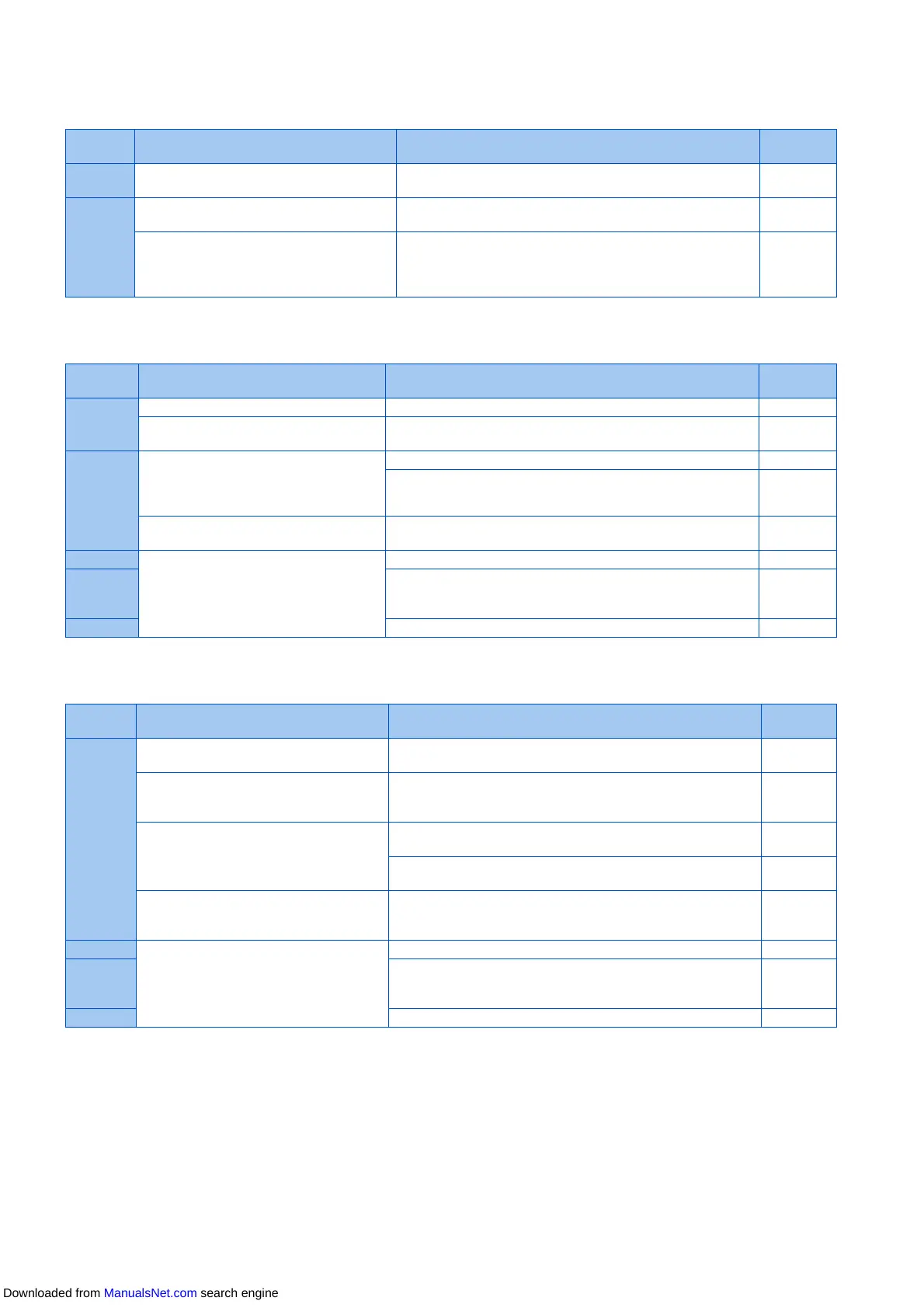

6.6.5 Motor rotates in the opposite direction

6.6.6 Speed greatly differs from the setting

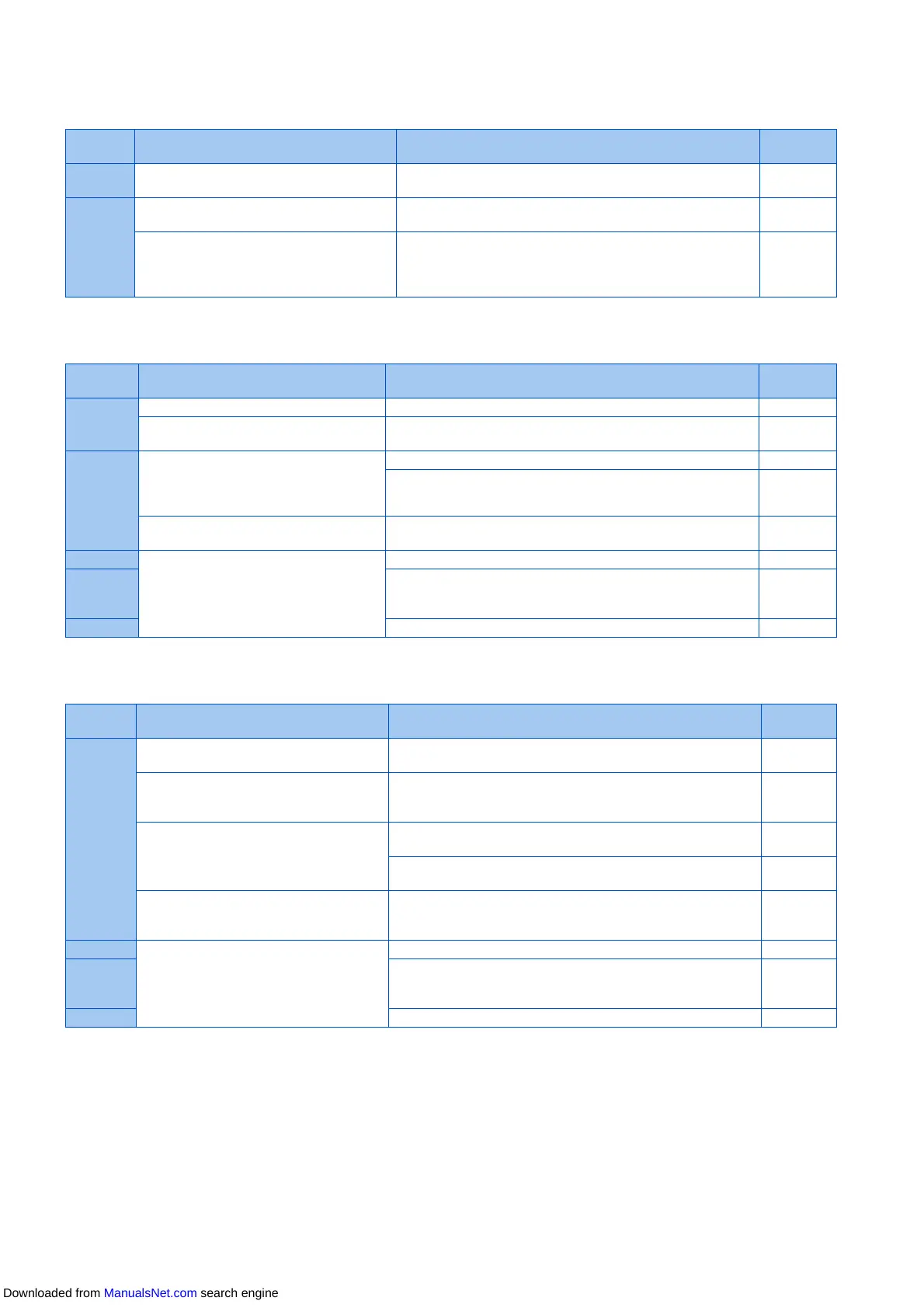

6.6.7 Acceleration/deceleration is not smooth

Check

point

Possible cause Countermeasure

Refer to

page

Main

circuit

The phase sequence of output terminals U, V

and W is incorrect.

Connect the output side terminals (terminals U, V, and W)

correctly.

50

Input

signal

The start signals (STF and STR signals) are

connected improperly.

Check the connection. (STF: forward rotation, STR: reverse

rotation)

60, 563

The polarity of the frequency command is

negative during the polarity reversible

operation set by Pr.73 Analog input

selection.

Check the polarity of the frequency command. 349

Check

point

Possible cause Countermeasure

Refer to

page

Input

signal

The frequency setting signal is incorrect. Measure the input signal level. —

The input signal lines are affected by

external EMI.

Take countermeasures against EMI, such as using shielded wires

for input signal lines.

93

Parameter

setting

Pr.1 Maximum frequency, Pr.2 Minimum

frequency, Pr.18 High speed maximum

frequency, and the calibration parameter

C2 to C7 settings are not appropriate.

Check the settings of Pr.1, Pr.2, and Pr.18. 287

Check the calibration parameter C2 to C7 settings. 357

Pr.31 to Pr.36, and Pr.552 (frequency

jump) settings are not appropriate.

Narrow down the range of frequency jump. 289

Load

Stall prevention function is activated due to

a heavy load.

Reduce the load weight. —

Parameter

setting

Set Pr.22 Stall prevention operation level higher according to the

load. (If Pr.22 is set too high, an overcurrent trip (E.OC[]) is likely to

occur.)

290

Motor Check the capacities of the inverter and the motor. —

Check

point

Possible cause Countermeasure

Refer to

page

Parameter

setting

The acceleration/deceleration time is too

short.

Increase the acceleration/deceleration time. 228

The torque boost (Pr.0, Pr.46) setting is not

appropriate under V/F control, so the stall

prevention function is activated.

Increase/decrease the Pr.0 Torque boost setting value by 0.5%

increments so that stall prevention does not occur.

551

The base frequency does not match the

motor characteristics.

Under V/F control, set Pr.3 Base frequency and Pr.47 Second V/

F (base frequency).

552

Under Advanced magnetic flux vector control or PM motor control,

set Pr.84 Rated motor frequency.

177

Regeneration avoidance operation is

performed.

If the frequency becomes unstable during regeneration avoidance

operation, decrease the setting of Pr.886 Regeneration

avoidance voltage gain.

572

Load

Stall prevention function is activated due to a

heavy load.

Reduce the load weight. —

Parameter

setting

Set Pr.22 Stall prevention operation level higher according to the

load. (If Pr.22 is set too high, an overcurrent trip (E.OC[]) is likely to

occur.)

290

Motor Check the capacities of the inverter and the motor. —

Downloaded from ManualsNet.com search engine

Loading...

Loading...