617

6. PROTECTIVE FUNCTIONS

6.6 Check first when you have a trouble

1

2

3

4

5

6

7

8

9

10

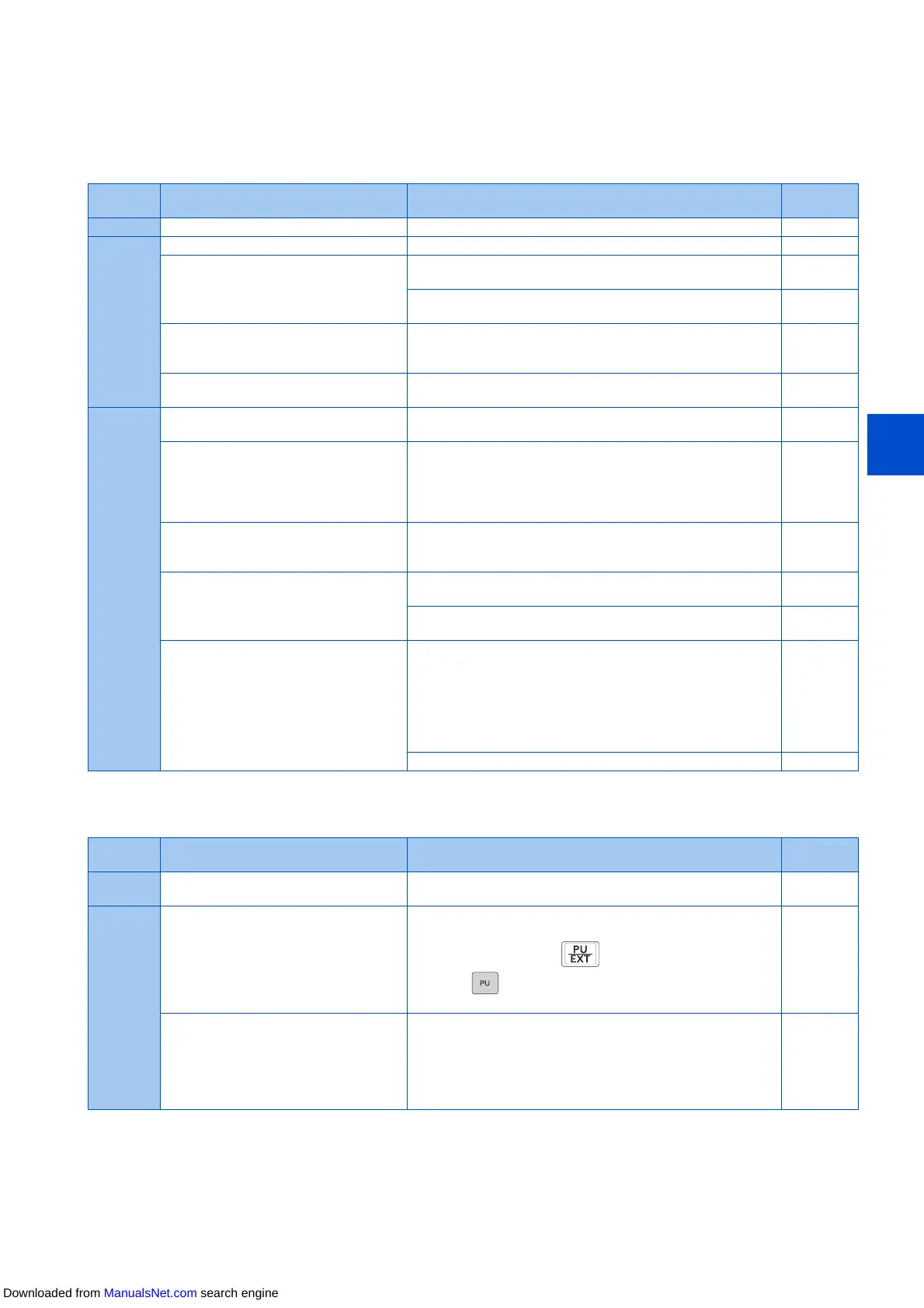

6.6.8 Speed varies during operation

Under Advanced magnetic flux vector control, the output frequency varies between 0 and 2 Hz as the load fluctuates. This is

a normal operation and not a fault.

6.6.9 Operation mode is not changed properly

Check

point

Possible cause Countermeasure

Refer to

page

Load The load varies during an operation. Select Advanced magnetic flux vector control. 177

Input

signal

The frequency setting signal is varying. Check the frequency setting signal. —

The frequency setting signal is affected by

EMI.

Set filter to the analog input terminal using Pr.74 Input filter time

constant, Pr.822 Speed setting filter 1, etc.

355

Take countermeasures against EMI, such as using shielded wires

for input signal lines.

93

A malfunction is occurring due to the

undesirable current generated when the

transistor output unit is connected.

Use terminal PC (terminal SD when source logic) as a common

terminal to prevent a malfunction caused by undesirable current.

65

A multi-speed command signal is

chattering.

Take countermeasures to suppress chattering. —

Parameter

setting

Fluctuation of power supply voltage is too

large.

Under V/F control, change the Pr.19 Base frequency voltage

setting (approximately by 3%).

552

The Pr.80 Motor capacity and Pr.81

Number of motor poles settings are not

appropriate for the motor capacity under

Advanced magnetic flux vector control or

PM motor control.

Check the settings of Pr.80 and Pr.81. 177

Wiring length exceeds 30 m when

Advanced magnetic flux vector control or

PM motor control is performed.

Perform offline auto tuning 383

Under V/F control, wiring is too long and a

voltage drop occurs.

In the low-speed range, adjust the Pr.0 Torque boost setting by

0.5% increments.

551

Change the control method to Advanced magnetic flux vector

control.

177

Hunting occurs by the generated vibration,

for example, when structural rigidity of the

load is insufficient.

Disable automatic control functions, such as energy saving

operation, fast-response current limit function, regeneration

avoidance function, Advanced magnetic flux vector control, stall

prevention, and online auto tuning.

For PID control, set smaller values to Pr.129 PID proportional

band and Pr.130 PID integral time.

Lower the control gain to increase the stability.

—

Change the Pr.72 PWM frequency selection setting. 218

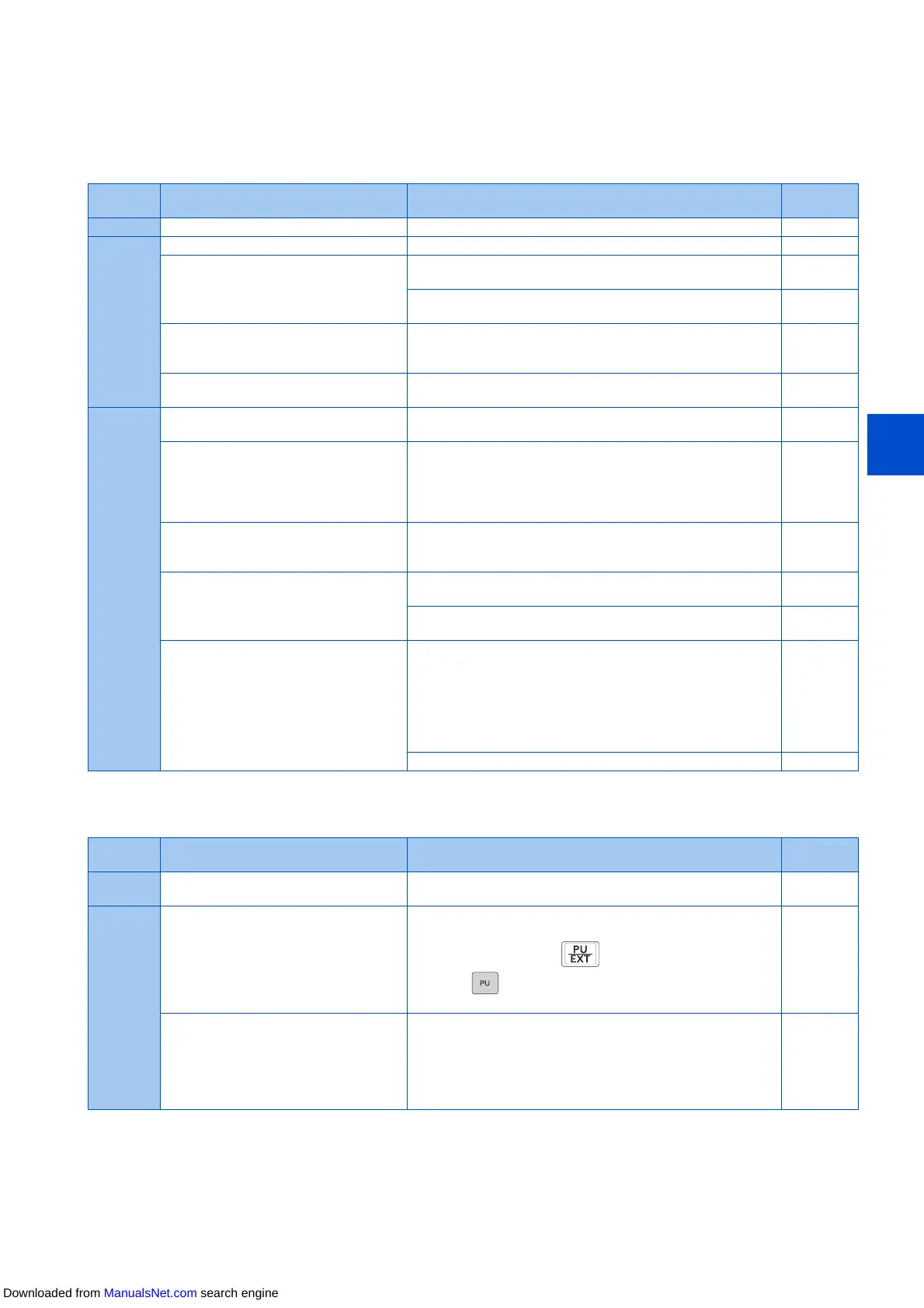

Check

point

Possible cause Countermeasure

Refer to

page

Input

signal

The start signal (STF or STR) is ON.

Check that the STF and STR signals are OFF.

When either is ON, the operation mode cannot be changed.

60, 563

Parameter

setting

The Pr.79 Operation mode selection

setting is not appropriate.

When the Pr.79 is set to "0 (initial value)", the operation mode is the

External operation mode at power ON. To switch to the PU

operation mode, press the key on the operation panel

(press the key on the parameter unit (FR-PU07)). At other

settings (1 to 4, 6, 7), the operation mode is limited accordingly.

240

Operation mode and a writing device do not

correspond.

Check Pr.79 Operation mode selection, Pr.338 Communication

operation command source, Pr.339 Communication speed

command source, Pr.550 NET mode operation command

source selection and Pr.551 PU mode operation command

source selection, and select an operation mode suitable for the

purpose.

240, 251

Downloaded from ManualsNet.com search engine

Loading...

Loading...