3Installing the option devices

Installing the operating range change (RV-2FR series)

3-51

(3) Installation procedure

The installation procedure of the J2 axis operating range change is shown below.

When installing this option, you should move the J2 axis to the 0 degrees by jog operation previously, and do this

work.

When installing this option for safety, you should cut off the power supply of the con

-

troller.

Each screw should be tightened with 4.6 Nm torque. Please confirm the screws are

surely tightened by 4.6 Nm torque before moving the robot.

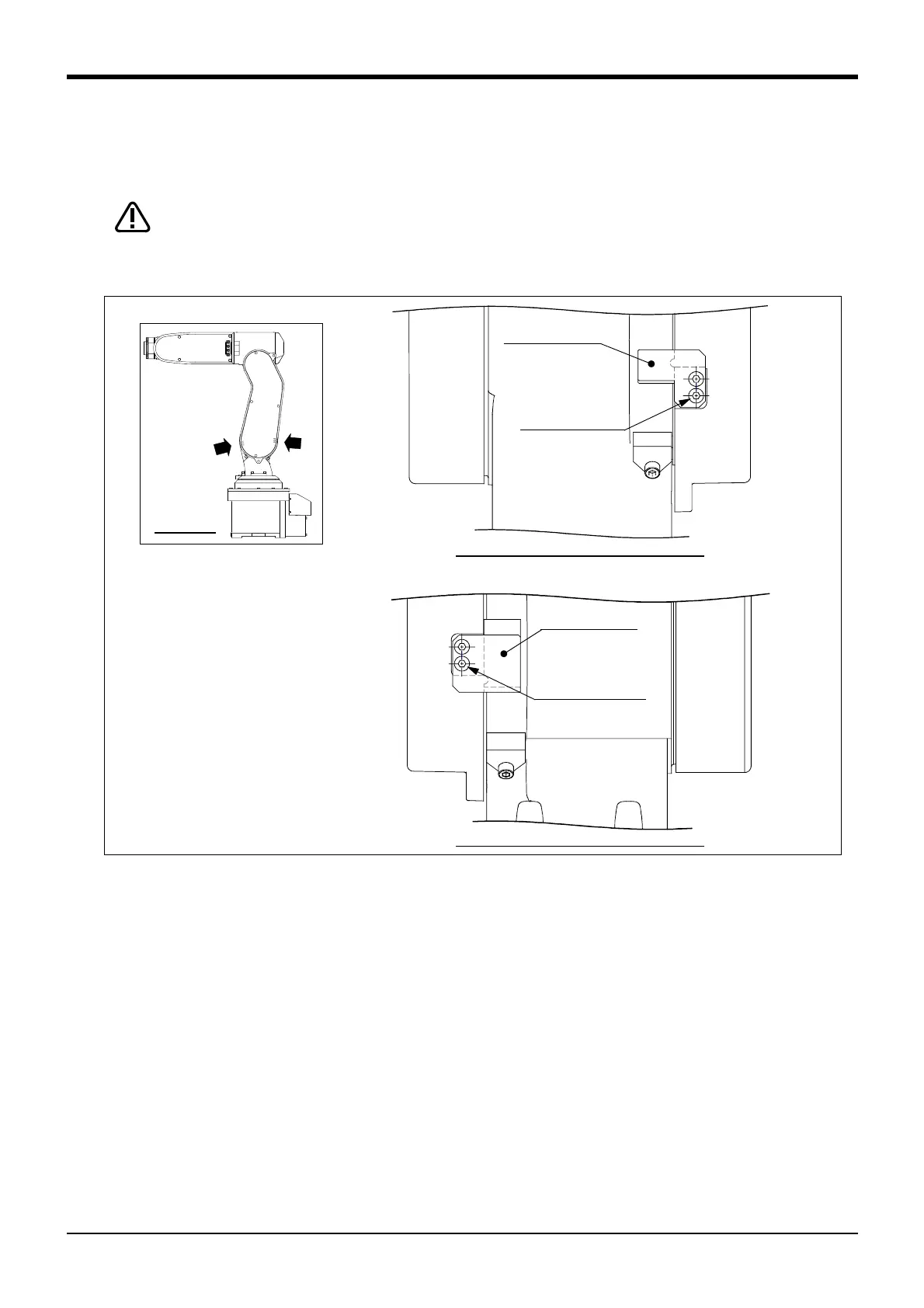

Fig.3-2 : Installation procedure of optional stoppers

1) Refer to Table 3-4 and confirm the stopper corresponding to the angle to change.

With the combination of angles of a plus side and a minus side, both A and B stoppers are required to be

installed.

2) Refer to Fig. 3-2 and install the required stopper to the installation position. Tighten screws firmly to fix the

stopper. (Tightening torque: 4.6 Nm)

(4) Setting the parameter

Specify the operating range to parameter MEJA and the mechanical stopper angle to parameter MORG with

appropriate values (variable angles given in Table 3-4) by the following steps.

1) Turn on the power supply.

2) Set up the operating range changed into parameter MEJAR.

MEJAR: (***, ***, J2 minus (-) side, J2 plus (+) side, ***, ***, ...).

3) Set up the - side mechanical stopper angle changed into parameter MORG.

MORG: (***, J2 minus (-) side mechanical stopper angle, ***, ...).

Note) Refer to the separate "Instruction manual/Detailed Explanation of Functions and Operations" for the

details of the setting method.

Stopper A

Screw

(2-M4x10 )

View A: Stopper A installation position

Side view

A

B

Stopper B

View B: Stopper B installation position

Screw

(2-M4x10)

Loading...

Loading...