7. APPLICATION INSTRUCTIONS

7 − 128

MELSEC-A

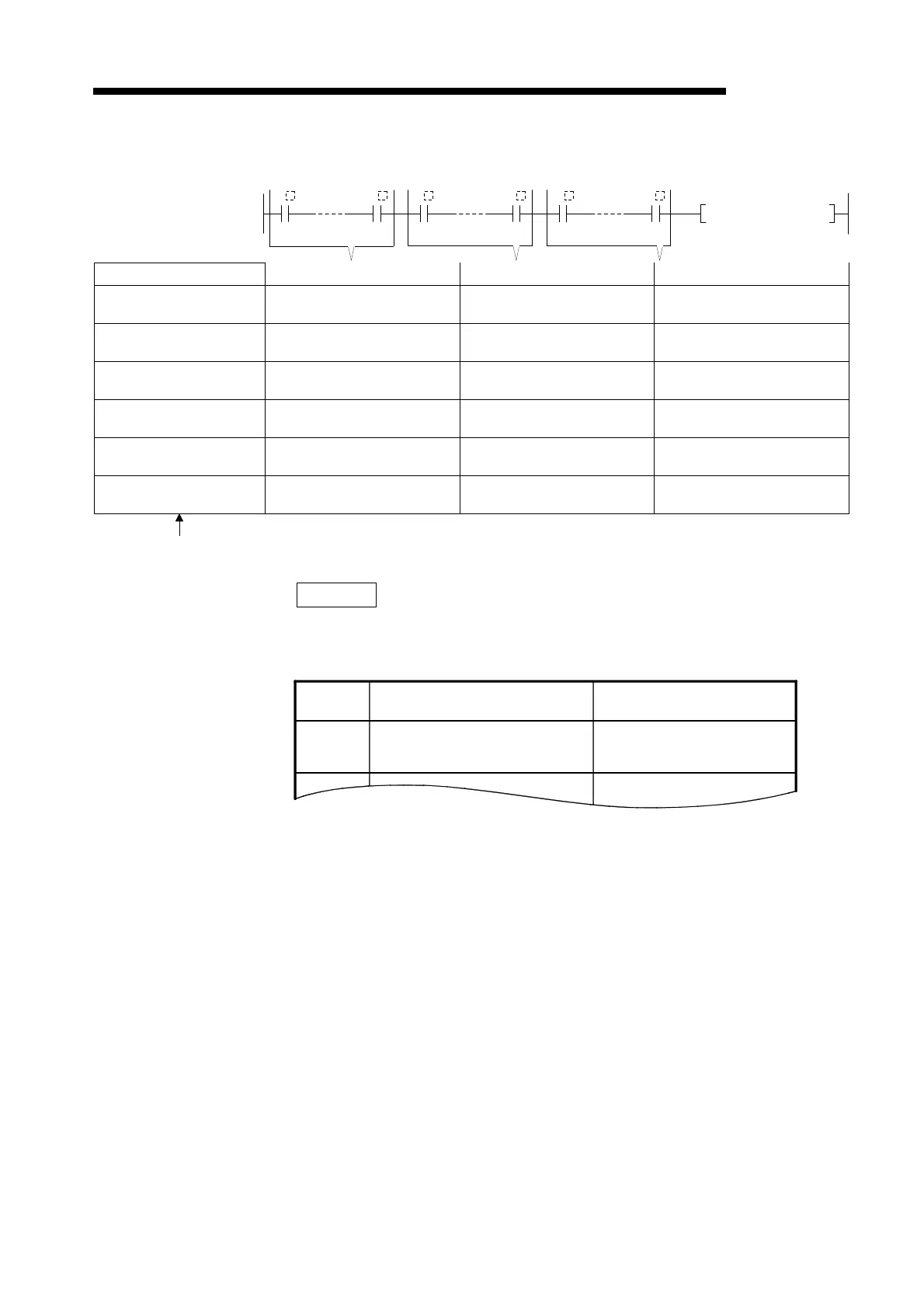

(8) Error codes stored in (D2) by the CHK instruction vary with conditions

establish-ed as shown below.

Condition established Condition Nos. 1 to 50 Condition Nos. 51 to 100 Condition Nos. 101 to 150

Condition No. 1

(data of error code No. 1)

100+ {2× (contact No.) -1 400+ {2× (contact No.) -1 700+ {2× (contact No.) -1

Condition No. 2

(data of error code No. 2)

101+ {2× (contact No.) -1 401+ {2× (contact No.) -1 701+ {2× (contact No.) -1

Condition No. 3

(data of error code No. 3)

200+ {2× (contact No.) -1 500+ {2× (contact No.) -1 800+ {2× (contact No.) -1

Condition No. 4

(data of error code No. 4)

201+ {2× (contact No.) -1 501+ {2× (contact No.) -1 801+ {2× (contact No.) -1

Condition No. 5

(data of error code No. 5)

301+ {2× (contact No.) -1 601+ {2× (contact No.) -1 901+ {2× (contact No.) -1

Condition No. 6

(data of error code No. 6)

300+ {2× (contact No.) -1 600+ {2× (contact No.) -1 900+ {2× (contact No.) -1

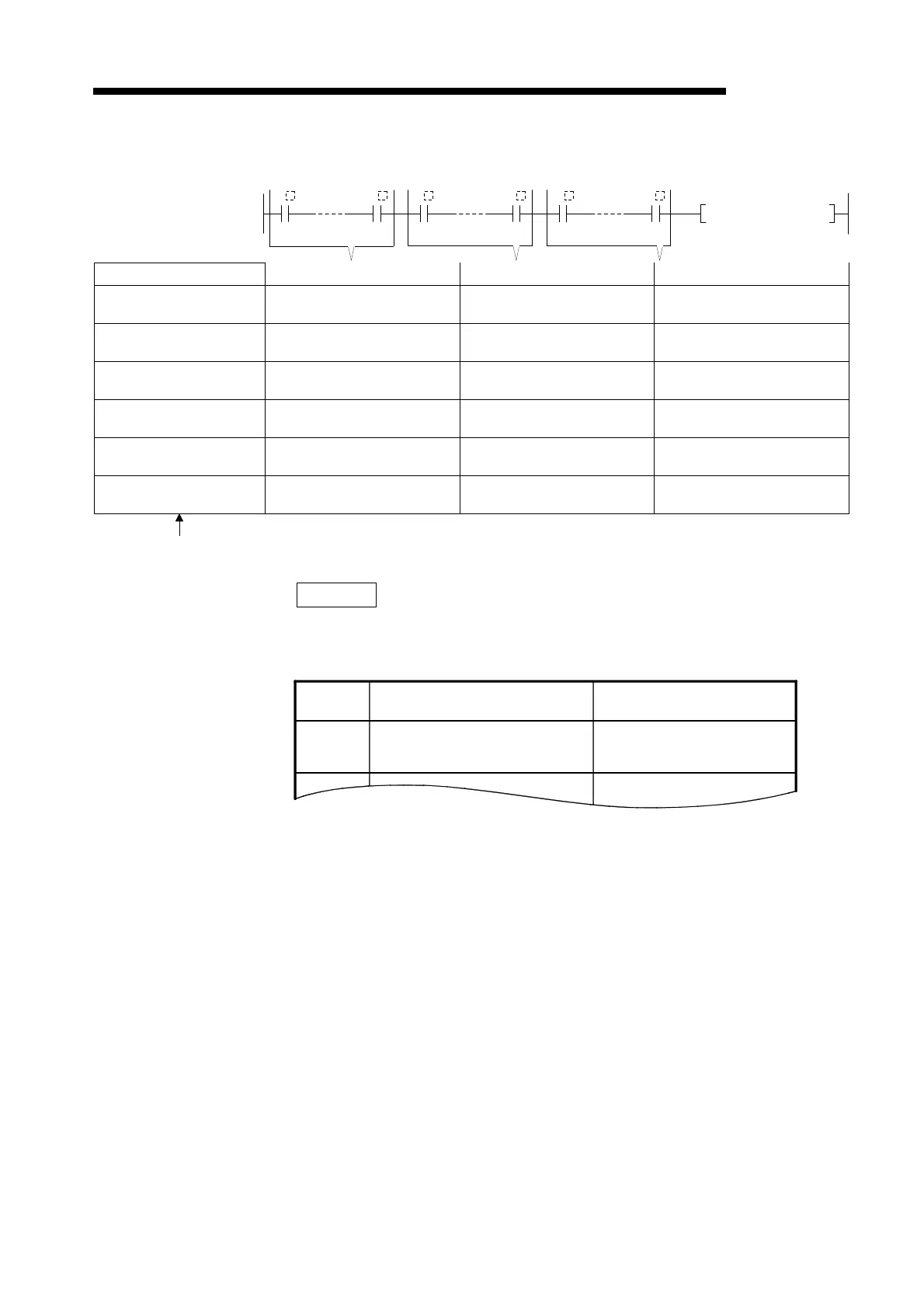

REMARK

Error code numbers displayed after the CHK instruction execution indicate kind of the error

occurred. Prepare a troubleshooting table corresponding to the system for quick remedies.

Refer to (2) for conditions.

Error code

No.

Cause Corrective action

301

Conveyor 1: Backward run occurred

when the forward stroke end sensor

• Check limit switch X1.

• Check the conveyor.

X X X X X X

Contact

No. 1

Contact

No. 50

Contact

No. 51

Contact

No. 100

Contact

No. 101

Contact

No. 150

CHK (D1) (D2)

P254

Loading...

Loading...