case

lo pre

vent

oil from leaking alo

ng

this part

of

crankshart. The oil seal

is

doweled

to

take a

given

position.

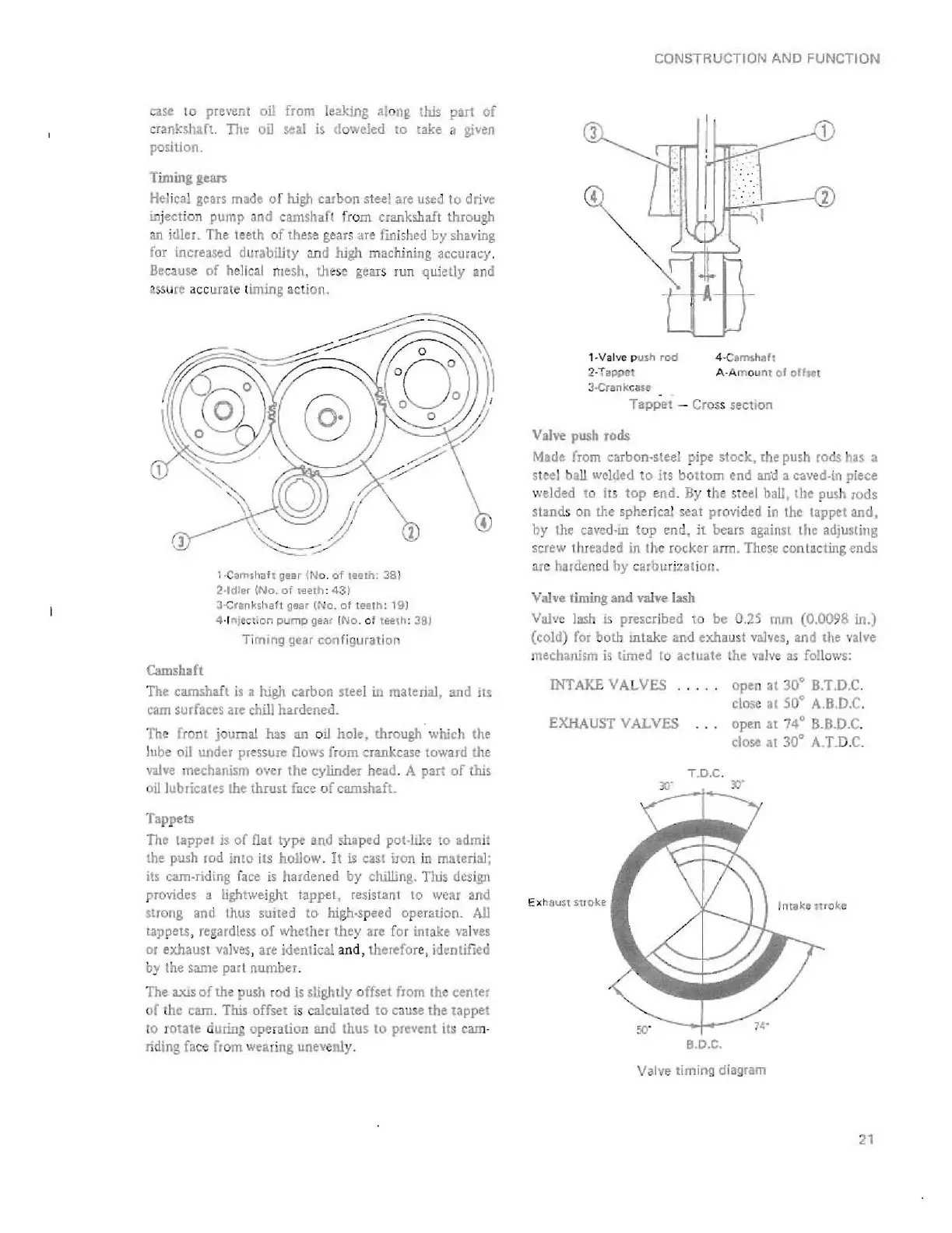

lUlling gears

Hel

ical gcars made of

hJgh

carbon steei are used

to

drive

injection pump

an

d camshaft from crankshaft through

an

i

f.ller.

The teeth

of

thest

gears

il

re

fll1

i

shed

by shaving

for

increased durability

an

d

.high

milchining accuracy.

Be

cause

of

he

ll-cal

mesh,

tl1e

se gears run

qu

ietly and

a

SSll

re

accurate llrriing

attion.

l

Cam,hart

1 ,C"rru.haft

gear

~N

o

.

of

lea In:

38

}

2'·ldler

~No.

of

ItI<i!th

:

43)

J-C'lnksn.aft gear

(No.

of

te

l!l

Th: 1

9)

4

·l

njtc

tion

pump

geM

(

No

. of te-e,h :

3BJ

Timing

gear

configuration

The -camshaft

is

a hiSh carbon steel in material, and its

cam surfaces are

chill

hardened.

Tn

o rronl

jou

rnal has an o

il

hole, through which the

lube oil under pressure flows from crankcase toward the

valve

mechanism over the cylinder head. A part

of

this

iI

lubricales the thrust face

of

camshaft.

Tappets

The lapp.1

is

of

fl.1 type and >hoped

pal.~ke

to admit

the push

fod into its hollow.

It

is cast iron

in

m.a.terial;

its

cam·riding

face

is:

hardened by chilling. This design

provides a lightweight tappet,

res

i

-S1ant

to wear and

strong and Ihu,

,ui«d

to high-speed operation.

All

tappets, regardless of whether

they

oro

for intake v,lves

or

exhaust

valves

,

art

idenheal and, therefore I idenlified

by

the

~e

part number.

The

axiS

of

the push rod

i,

sUghtly offset from Ihe eenle,

of

the cam. This offset is calculated

10

cause the tappet

to r

otate

during operation and thus

to

prevent its cam·

riding

face

fr

om wtaring

unev

enly.

CONSTRUCTION AND FUNCTION

: ..•

~

-{2

'I

'

-V

al

ve p

uih

rod

4

-C

arml\3fl

2·TaPP8t A·Amo

unt

of

of"et

3-CrankcosCl

Tappet - Cross sectIon

Val"" push rods

Made rrom carbon·steel pipe stock, the purn rods

h"

•

steel

ba

ll

welded to its

boltom

end

an'd

a caved-

in

piece

welded to

iu

top

end

.

By

I

he

' leel bail, Ihe push

lods

stands on

the-

spherical seat provided in the tappet and,

by

the cavcd·m top

e.nd,

it

bears againSt the adjusting

screw

tlueaded

in

the rocker a

rm

. These contacting ends

are

hardened hy carburizalion.

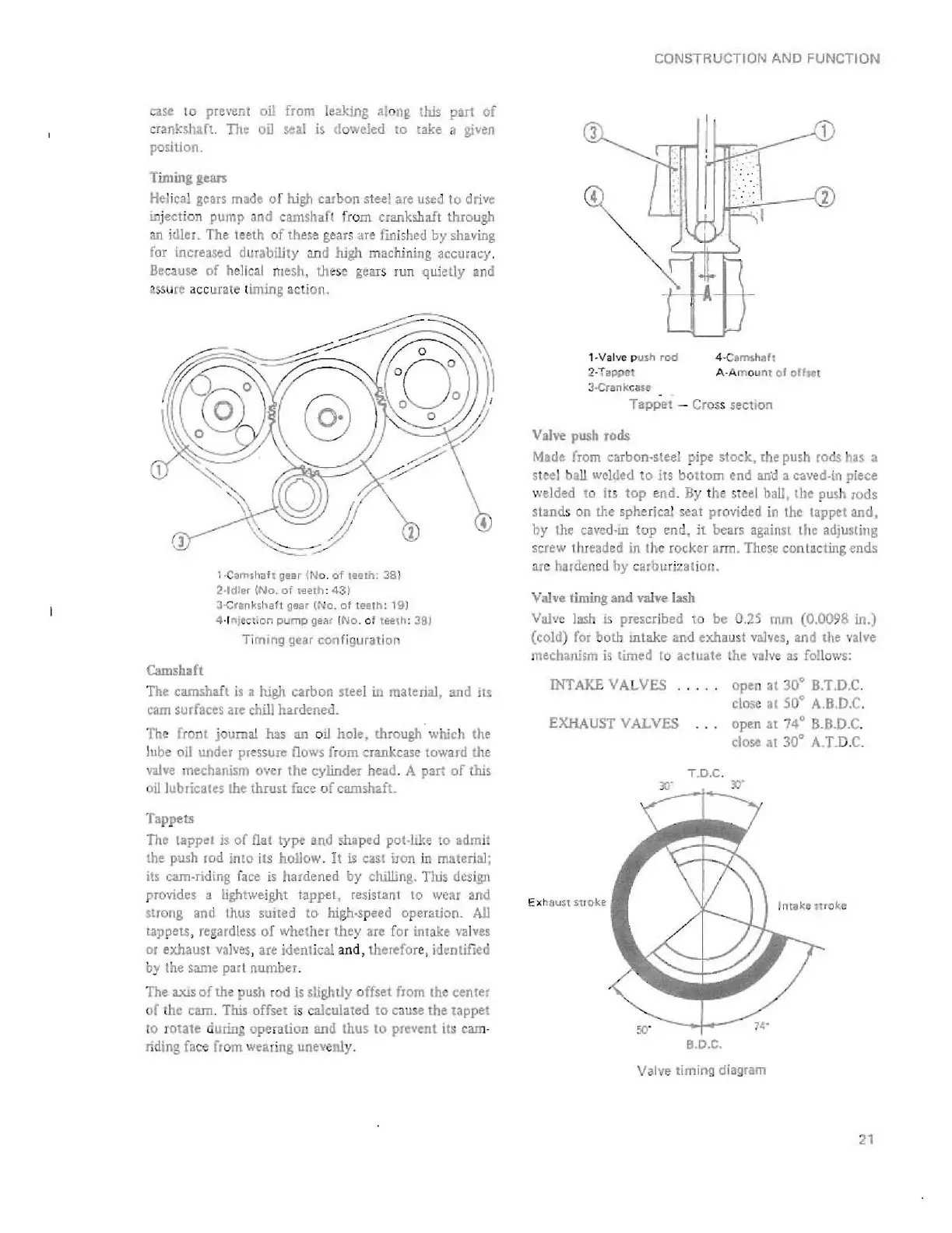

Valv.

timing and valve

Ia<h

Valvo

laID

IS pre,cribed to be 0 .

25

mm (O,0()98 In.)

(cold)

fOI

both Inlake

.nd

exh.

u,

t vah'

es

, and Ihe valve

mechanism

is

timed

[0

actuate the

valve

as

follows:

INTAKE

VA

L

SES

open

at

30'

B,T,D,C,

close

al

SO

'

A,B

,

D,C

,

EXHAUST VALVES open

at

74'

B.B

.D,C.

close al

30'

A. T

.D,

C,

Ex

n

{juH

s'rrok~

T.D.C

.

30'

lY

:::--;--....

B,O.C.

w

Valve timing diagram

Intake

:rlro,ke

21

Loading...

Loading...