CONSTRUCTI

ON

AND F

UNCTION

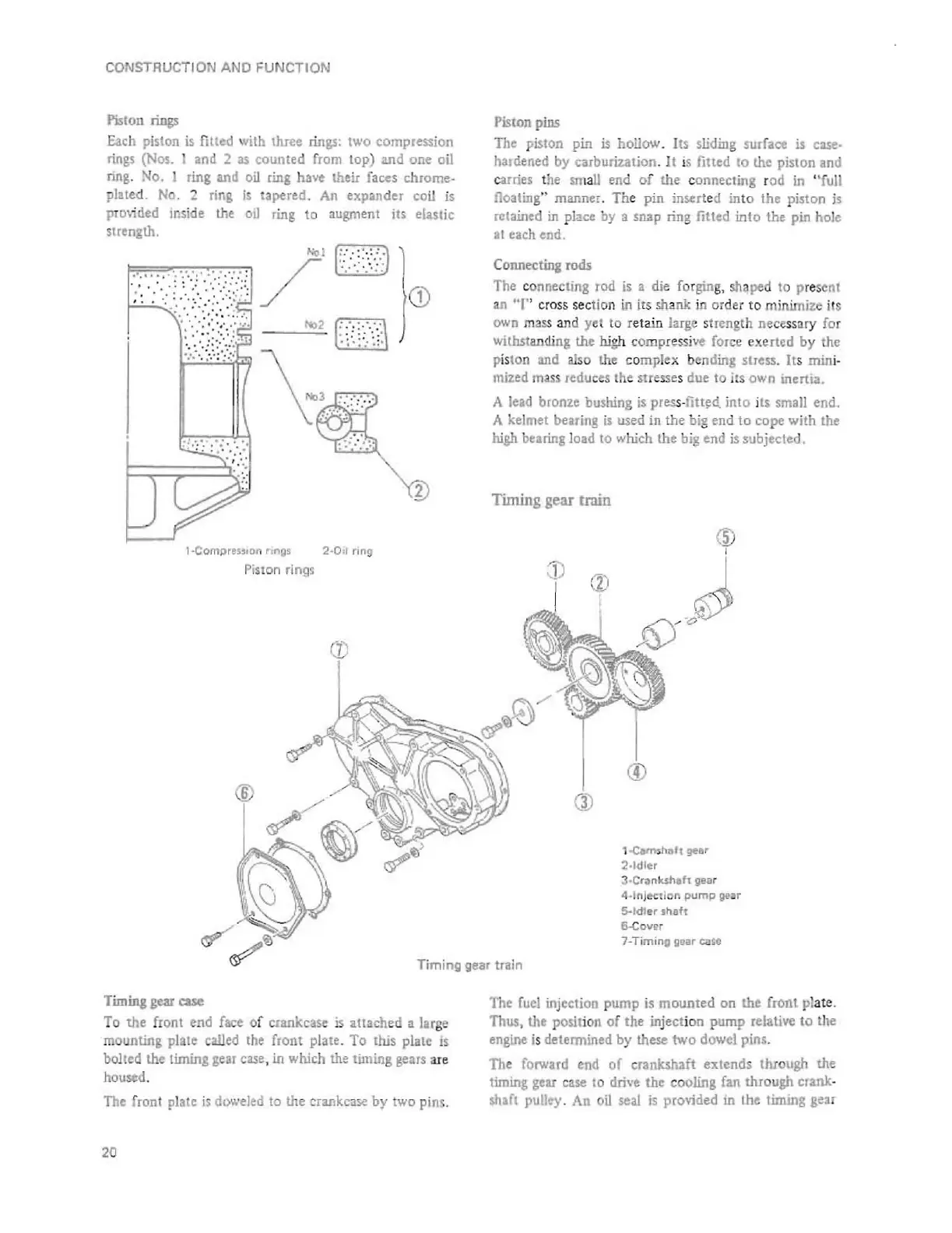

Piston

rings

Each

pi,ton

i,

fitted with three rings; two compr.ssion

ring' (Nos. 1

and

2

as

counted from top) and

on.

oil

n

ng.

No.

1 ring and

oil

ring have their faces chrome·

plaled .

No.

2 ring

Is

tapered.

An

expander co

il

is

pT

01;

i

ded

msi

d

e.

the

oil

ring

to

a

ugment

its

elaslic

sirength,

..

.

...

..

'

..

CD

:"'

:

:

:

\

,,

:~

2

' ·ComPrnsrDII rings

2·0;f

ring

Pisto

n

ri

ngs

Piston pins

The piston pin

is

hollow. Its sliding surface is c"",·

hardened

by

carbumation.

It

is fitted to the piston and

c

arri

es t

he

smaU

en

d of the connecti

ng

rod

in

"f

ull

noatin

g"

manner.

Th

e pin

insert

ed

in

to the piston i,

relained

in pl

"e

by a

sn.p

ring fitted into the pin hole

at

eac

h end,

Co

nnectlni rods

The connecting fad

is

a die

fo

r

gin

g,

sh

a

pe

d to p

re

se

nt

an

uro

cross

section

in

i

ts

sh

a

nk

in

or

der

to m

inim

iz

e

it

s

Own

mass

an

d yet to retain large st

ren

gth nece

ss

ary for

withst

andi

ng

th

e

hig

h. comp

ressi

ve

forc

e exe

rted

by

the

p

is

I

on

and

also the comp

lt

x bending

sbess

.

It

s min

i-

mized

mas

s

redu

c

es

the

st

res

se

s

due

to

it

s own mertia.

A

lead

bronze bushing

is

pr

ess

-fitted, into i

ts

small end.

A

ke

l

met

bearing

is

use

d

in

th

e

big

end

to cope with

the

high

bearing load

to

whi

ch

the big end is subjected.

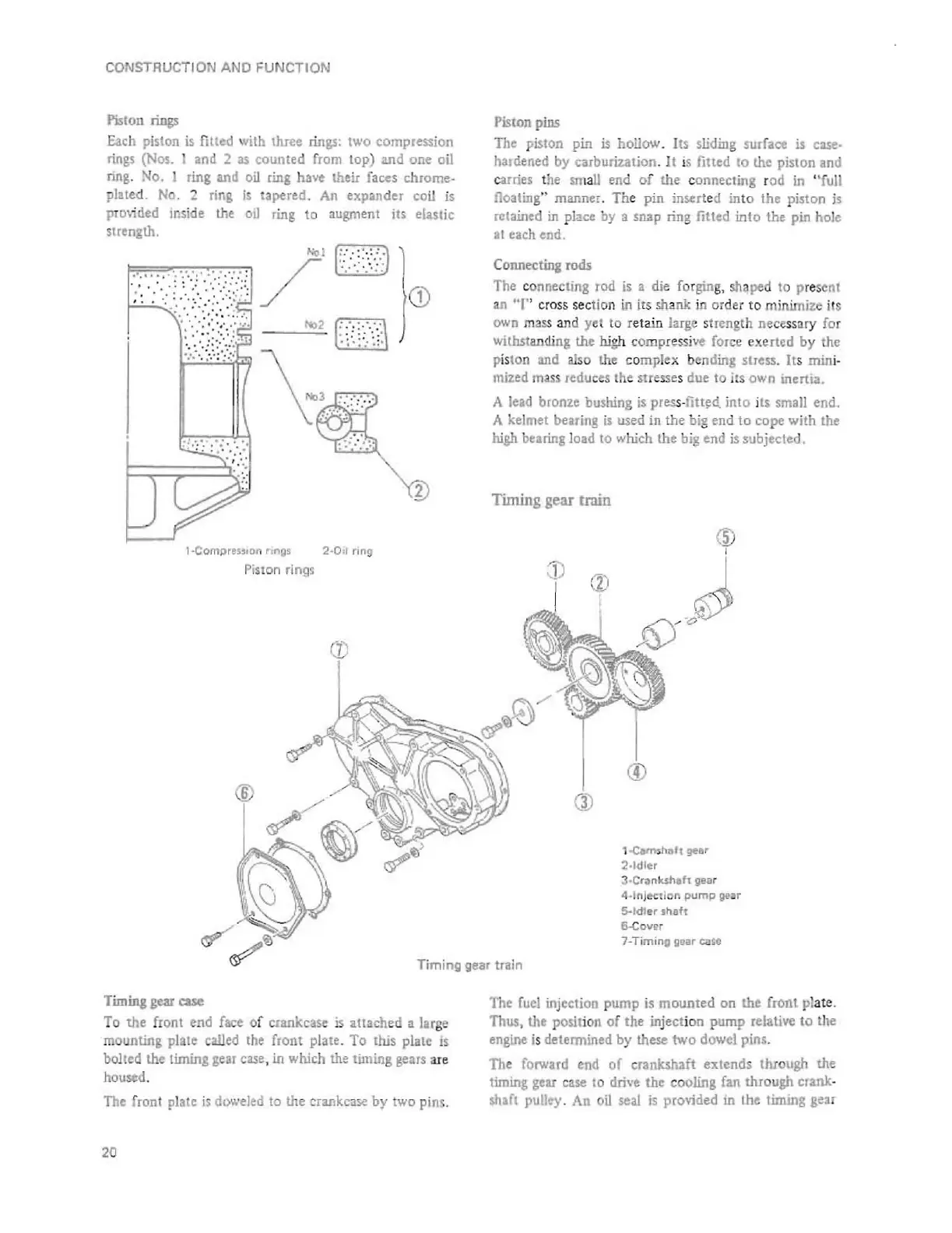

Timing gear train

'

~"1:I1t

g!'ar

2·ldler

3.C

...,

nksh

,h

g9sr

4.l

nJee

~jon

pump

gear

5-ldter

shah

6

--Co

ve

r

7

·Ti

ming gellr

ca

~o

Ti

ming

gear

train

Timing

gear

ease

o

the

fr

ont

end

face

of c

rankcase

is

attach

ed a

lar

ge

mo

unting plate called

the

front plate _

To

this plate

i,

bolt

ed

the

linning

geat

case

,

in

which the timing gears are

housed.

The

fron

t plate

is

doweled

to

the

crankC3se

by two

pi

ns

.

20

The fuel

in

jecti

on

pump is mounted on the f

rOl'lt

pl

ate,

Thus, the position of the

in

jection pump relative to the

engine is determined

by these two dowel pins.

The forward

end

of

crankshaft extends through the

tOOing

gear

case to drive the cooling fan throu

gh

crank·

shaft

puUey

_

An

oil

seal

is

pro';ded in the tinting gear

Loading...

Loading...