by

the locating pins provided

on

the front place,

and s

ecu

re the cast

hy

tightening a

lot31

of

13

volts

.

InstaU

injection

pump

gear

cover (2).

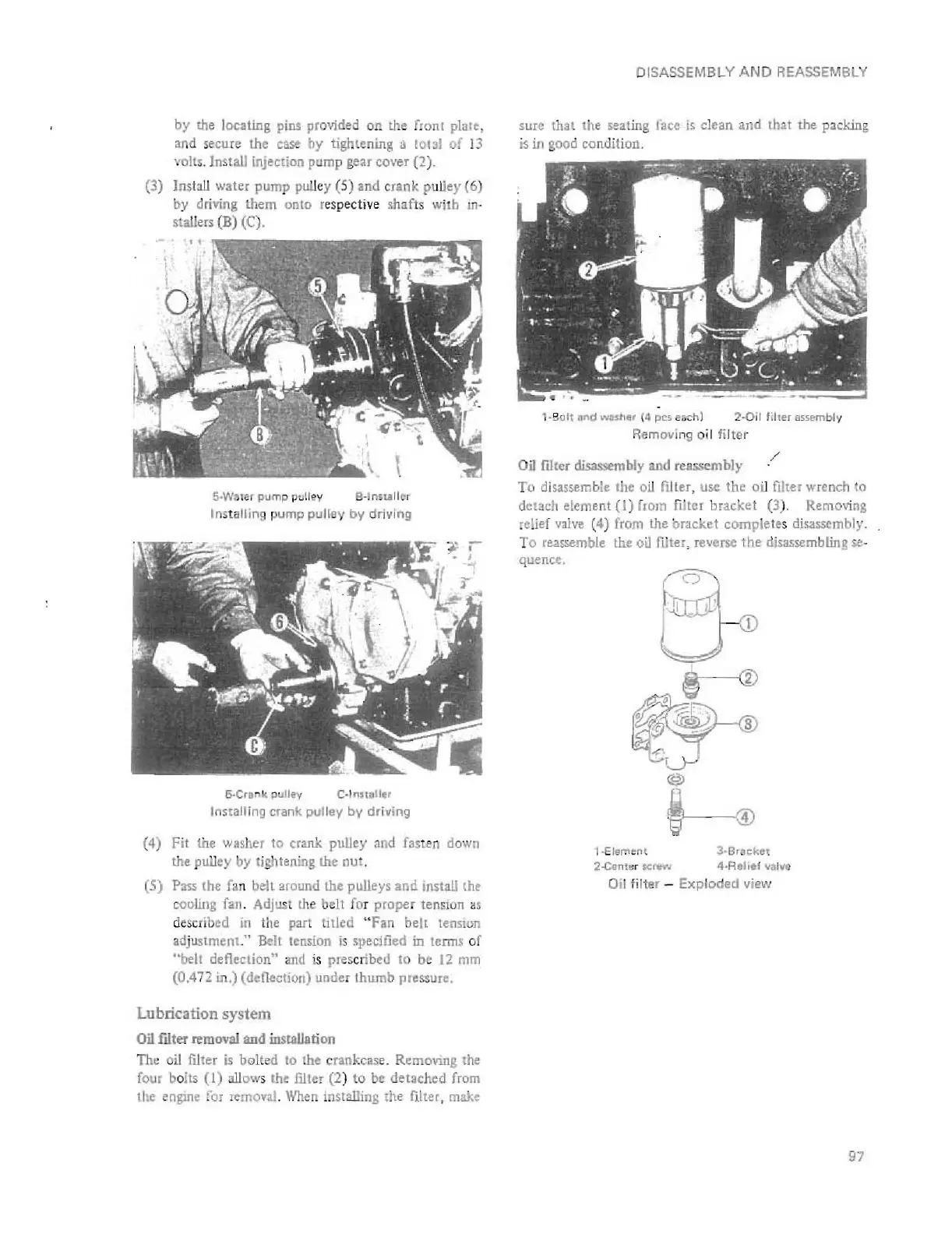

(3) Inslall waler pump pulley (5) and crank p

ull

ey (6)

by

driv

ing them onto respective shafts witb In-

stallers (B) (C).

5·W~

ner

pump

pulley

B-lnstallc~

I

ns

t allIng

pum

p polley by

dr

iving

!5·Crunk

pulley

C-

l

n,t.II.,

Ins[alling crank pull

ey

by drLving

~,

. ,

~

(4) Fit the washer to crank puUey and fasten down

the pulley by tightening the nut.

(5) Pass the

fa

n belt around the pulleys and install the

coollna

fan

.

Adjus

t

me

belt

fo

r

proper

tensIOn

i:!

S

d

escrib

ed

in

t

he

par

t tllied "

Fan

belt

tension

ad

j

ustment."

Belt

tension

is

specified

in

terms

of

"belt deflec.tion"

and

is presc

ribed

to

bt

12

nlm

(0.472 in.) (denectioll) uoder thumb pres;ure.

Lubrication system

on

fdter

removal

and

insraU.tion

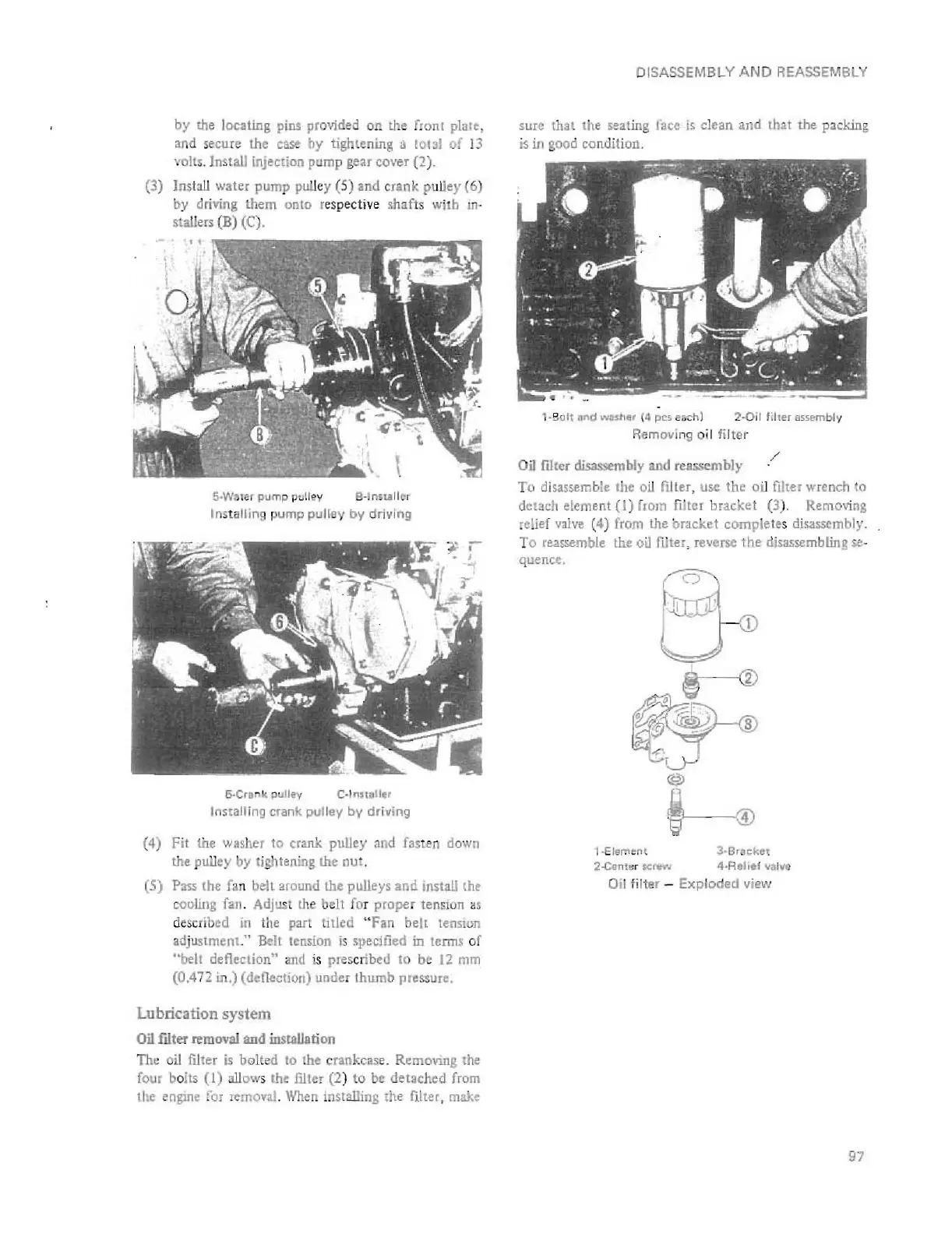

The oil filter

is

bolted to the crankcase.

RemoVlIlg

the

four bolts (1) allows the filter (2)

to

be detached from

the

engme

!'or

removal

.

When

installing [he fitter,

mak

e

DISASSEMBLY

AND

REASSEM6LY

sure that the seat

ing

face is clean and that the

packing.

is

ill

good

condition.

8

0lt

and

~$het

(4

p~

es'Ch)

2-Oil

filter

Bssembly

Removi

ng oil

fi

l

te

r

Oil

ftlter disassembly and r""ssembly

/

To disassemble the oil filter, use

the

oil filler wrench to

detach element (1) from filler bracket (3). Removing

relief .alv. (4)

from

the bruck,t completes disassembly.

To

re.assemb

le

the

oiJ

niter,

rev

erse

the

disassembling

Sot

·

quence.

o

1

h

1-

E

ll!lment

3~Brollol;ket

2-Ce-nte

r

K:

l

tw

4·Re

li.

f

valve

Oil filter - Exploded view

97

Loading...

Loading...