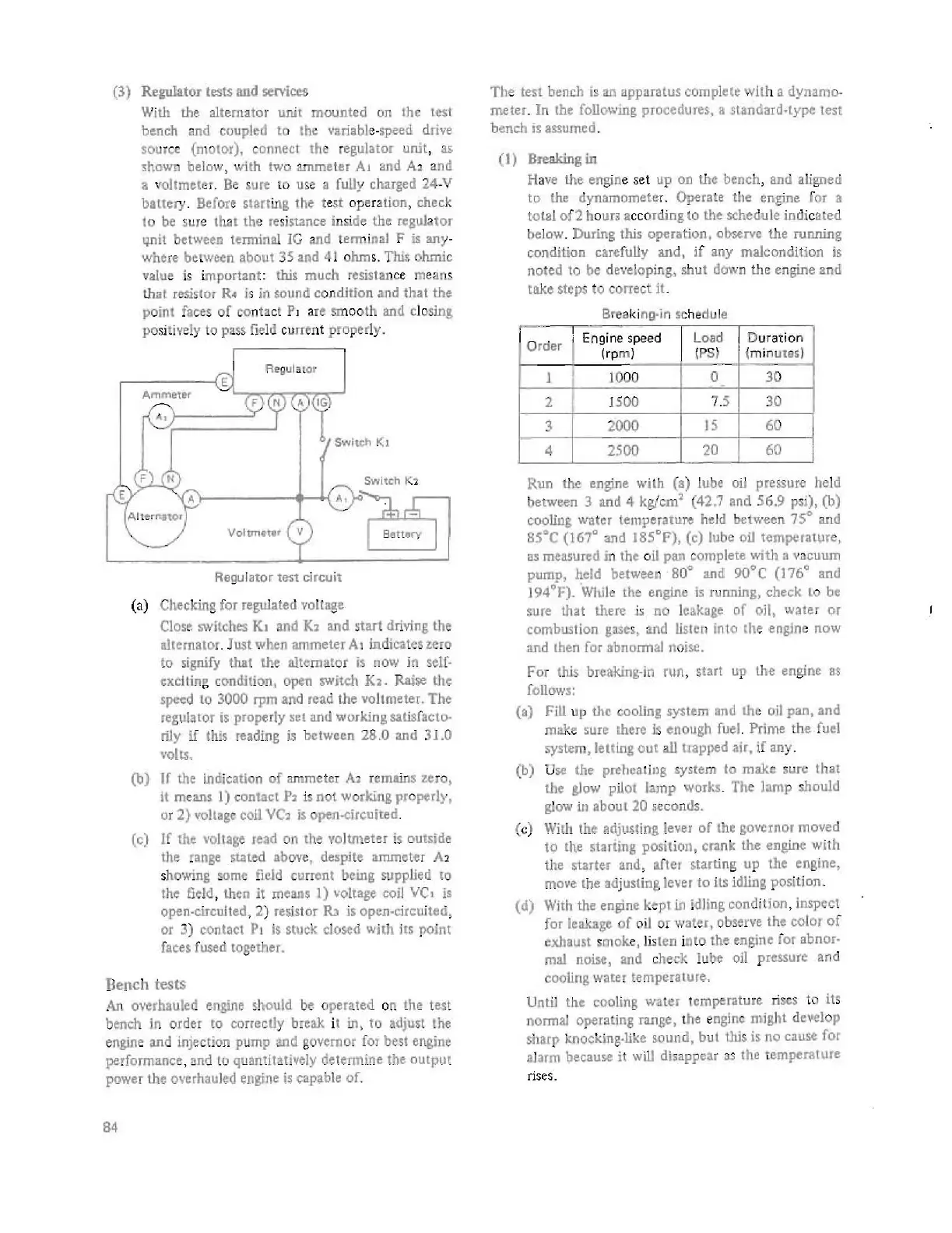

(3) Regulator tests and "'Mee:s

With the alternator unit

mounted

on

the

tes:t

bench

and

coupled to

Ihe

vari'ble-speed drive

source

(molor).

connect the regulator

unit

, as

:shown below·,

with

two

arruneter AJ and A

:i

and

• vohmeler. Be sure

10

use

a fully charged 24-V

battery

. Before starling

the

test o

pe

ration, check

to be su

re

thai the

re

si

stance inside the regulator

ijIlit between terminal

IG

and terminal F is

any

-

where

be

t

ween

about 35 and

41

o

hm

s.

This

ohmic

value is

important

: this

much

resista

nc

e means

that

resistor

R"

is in sound c

on

dition

and

that

the

point

faces

of

con

ta

ct Pl are smoo

th

and closing.

po

si

tively

to

pass.

fie

ld cu

rro

nt

properly

.

RE-Qula

t

or

E

Ammeter

A,

Switch Kl

" • I (

Voltmu.t

r

11

Regu

I ate r

le'St

ci

rcuit

(a) Checking for

regula

led

vo

lt

.ge

Close

switches K. and K, and

,tart

driving the

IIllenlalOr.

Just when ammeter A. indicatestero

to

,ignify that the alternator

is

nOw

in

,eJ[-

t:xclting condition. optn swjtch

K4.

Raise the

spe<:d

10

3000 rpm and read the

vohmeter.

The

regut

..

or

is

properly

"t

and

working

saliEf.cto·

riJy

if

this reading

is

between

28.0 and 31.0

VOllS.

(b)

If the indication

of

ammeter

A>

remains

z.

r

o,

1t

means

1)

t:ont.act

P2

is not working properly,

or

2)

volt,se

coil

YC,

i,

open-drcuited

.

(c) If Ihe

voltage

read on the voltmeter

i,

outside

the

range

stated above.

despHe

ammet-er

A2

showing

!Orne

field

currenl being supplied to

the

field

, then It means 1) "oltage coil VC, is

open.circuited, 2)

resistor

Rl

is open-circuited,

Or

3) conlact P,

is

stuck closed wilh ils point

faces fused logether.

Bench tests

An

overhauled e.

ngine

,hould

be

o

perated

on Ihe t

es

t

bench in order to

correc~y

break it

in

, to

.djust

lhe

engine

and

injectIOn

pump

3Jld

governor

fO!

besl engine

performance, and

to

quantitatively determine the output

power the overhauled

engine

is

capable of.

84

The

ten

bench

is

an appil.r3tus complete

wit

h a

dynamo-

meter.

In

the foliowinE, procedures. 8

standard·

type

test

bench

is

."umed

.

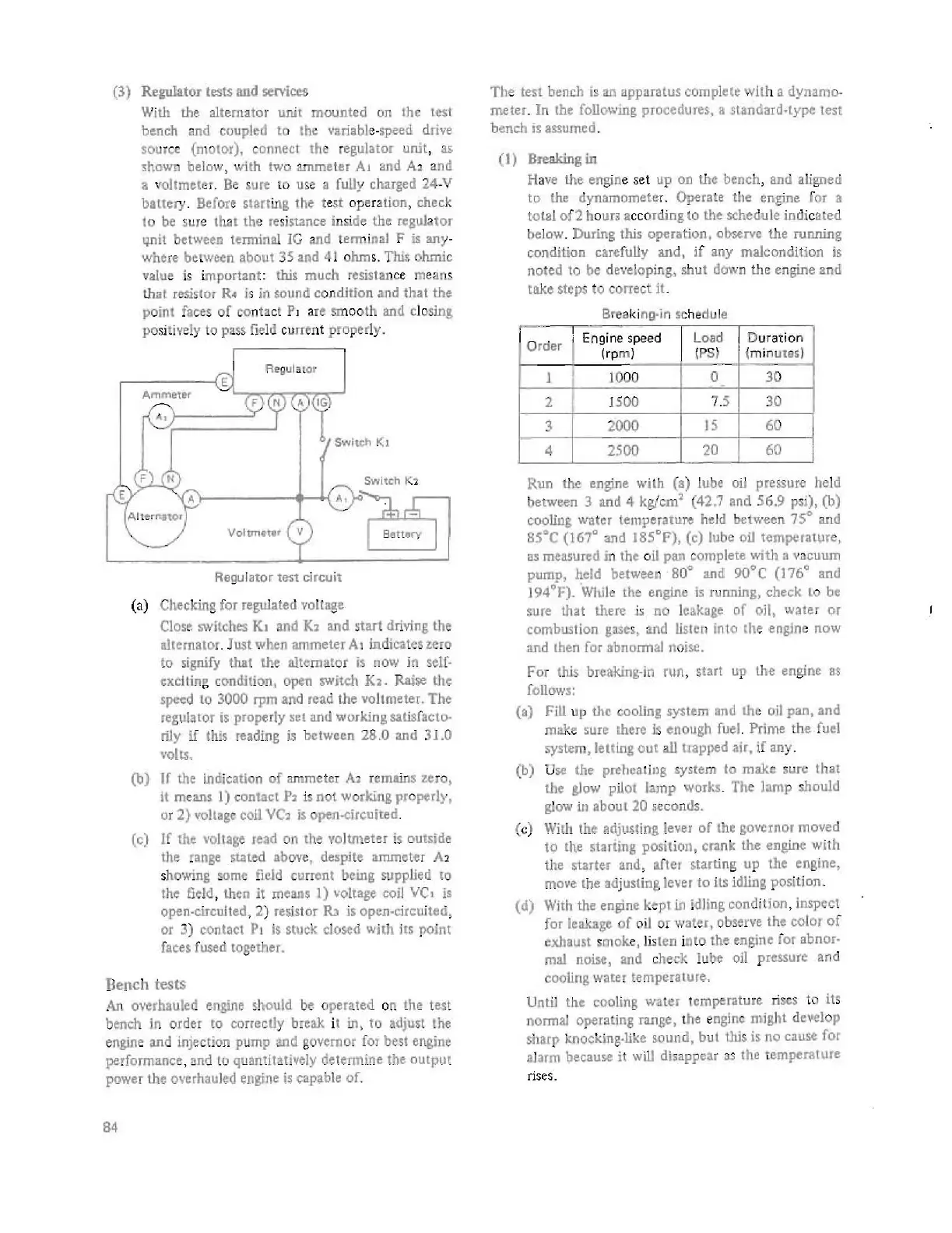

(I)

Breaking in

Ha

ve

the

engine set

up

011

the

bench, and aligned

to the

dynamomete

r. Operate

the

engine for a

total

of2

ho

ur::

acc

ording

to

the

schedule indic

i3ted

below. During this

opera

t

ion,

observe the

running

c-ondition

carefully and I

jf

any malcondition

is

noted

to

be

developi

ng,

shut

down

ti

le engine

and

take

steps

to

correct

it.

Breaking·in

s.c

hedule

,-

E·

d

Load

D

uratio

n

o d I ngme spee

r

er

(rp

m)

IPS)

(m

in

utes)

I

I

10

00

0 30

-

2 1

500

7

.5

30

3

2000

IS

60

4

2500

20

60

- -

----

Run

the engine with

(a)

l

ube

ail

pressure held

between 3

and

4 kg/em' (42.7 and 56.9 p,i), (b)

cooling

water

temperature

held

betwee

n

75

0

and

85'C

(167'

3lld

ISS'F),

(e) lube

oU

lem!X''''tpre,

as

measured

in

the oU pan complete with

i1

vacuum

pump, held between

80'

and 9O'C

(176'

and

194'F).

While

lhe engine

is

running, check

10

be

sure

that

there

is no leakage

of

oil. wate.r

or

combustion

gases.,

and

Iisltn into (he engine

now

and

then

for

abnormal noise.

For

this.

breaking·in run, start

up

the engine

as

fonows:

(a)

FiU

up the cooling system

and

the

oil

P31l,

and

make

,ure there

Is

enough

fuel

. Prime the fuel

system, lelling

ou'

all lIapped air,

if

any.

(b)

U

se

the preheating system

to

make

SUIt::

that

Ihe glow pilot lamp works. The lamp should

glow in

about

20

seconds,

(c) With

the

Adjusting

lever

of

the

governor moved

to

the

.1.riing pOSition , crank the engine with

Ih.

starter and , after slarting up the engine,

move Ihe

ad

justing lever

to

its idling posilion_

(d)

With

Ih.

engine kepI in idling condition, inspect

for

leakage

of

o

il

or wale{, ob,erv. the color

of

exhaust

s.

mok

e,

lis

ten i

nto

the

engine for

abnor·

mal

noise, and check lube

oil

pressu,. and

cooling

water

temperature.

Until the

C()oHng

wa

t

er

temperature-

ri

ses

to its

normal

operating

r"'go,

.

he

e

ogine

might develop

sharp knocking.like

sound,

but

this

is

no c.use for

alarm

because it

will

disappear

as

the temperature

rises.

Loading...

Loading...