Hints

for

f.cilitating

disassembly-reassembly

work

Engine disassembly

(al Orderlin

ess

is important.

Have

work

benohes ond

parts

t

ray

s

in

goo

d

c

ondition

~

cle

an

and

tidy.

Washing sinks and pans

sh

ou

ld

be

neat and ready

for us..

Have

the dis,,",sembled

part

s plac

ed

in

respec

tive

tray

s, keepmg a group of

assoc

ial

cd

parts

in

the

same

tray

ror

easy

id

entification.

(b) Before

se

parating two parts, be sure

to

make

match

marks

a~

necessary.

Even

for iliost

parts

to

wh

ic

n positional

mat

c

hing

is.

not

crit

i

cai,

such

marks will facilitate reassembly wor

k.

(e) Signs of some defects or naws are visible during

d

is

3ssembly but

JIlay

di

s

ap

pea

r when the

disassem-

bled

part

s

are

wa

sh

ed

clean

.

Leave

your

fIndings

on

re

cord

when

such

signs

are

noted .

(d)

Use

the right kind

of

tool for each disassembling

job.

in

order

to protect

the

parts

and

to speed up

'he

work

.

(e)

Handle

bearU'g8

and busrung' and the

like

with

care. They

are

critical parts: a little nick could

ma

ke

them

unfit

[or

re-use.

Engine

re

....

mbly

(

a)

Mak

e

it

a

rule

not to

rc·use

ditty

parts.

in

reassem

·

bly.

Oil

seals

and

beari1lgs

must be

particul"ly

cle.n

. !lefore instolling them, be sure

to

cle

..

, the

bores

for

admit

ting them,

(b)

It

is

a good practice not to re·use those gaskets

and

sealing

members

removed

f

rom

the

engine

that

ha

s been in long service. Use of replacement

partS

is

m

ore

economical as f

ar

as

gaskets

and

the

like

are

c

oncem~d.

(e) !lefore fitting a running part, be sure to oil its

stiding surf.c

..

.

Use

clean, fresh

'ngine

o

il

.

(d) Hav.

the speCified sealing compoWld on han

Use

of

the

compound is

pres

cr

ibed for most

of

sealing

pa

rts.

(e) Torque limits

ar

e specified for some bolts and

nu

ts

.

Be

sure

to

use

torque

'wrenches

and

to

re

r

er

to t

he

sp

ecified values

of

torque limits.

Engine

dismounting

and

mounting

T

he

engine

and

t

ransmis

si

on

a.re

lo be L

aken

down

tog.thor from the machi.ne. The two must be combined

On

the

bench

and

then

remounted

as

a unit.

The

dis-

mounting and mounting procedures are set fo

rth

in

a

nother

manuaJ.

Dt

SASSEMBLY

AND

REASSEMB LY

Rocker

arms

and

rocker

shaft

Rocker shaft

....

mbly removal

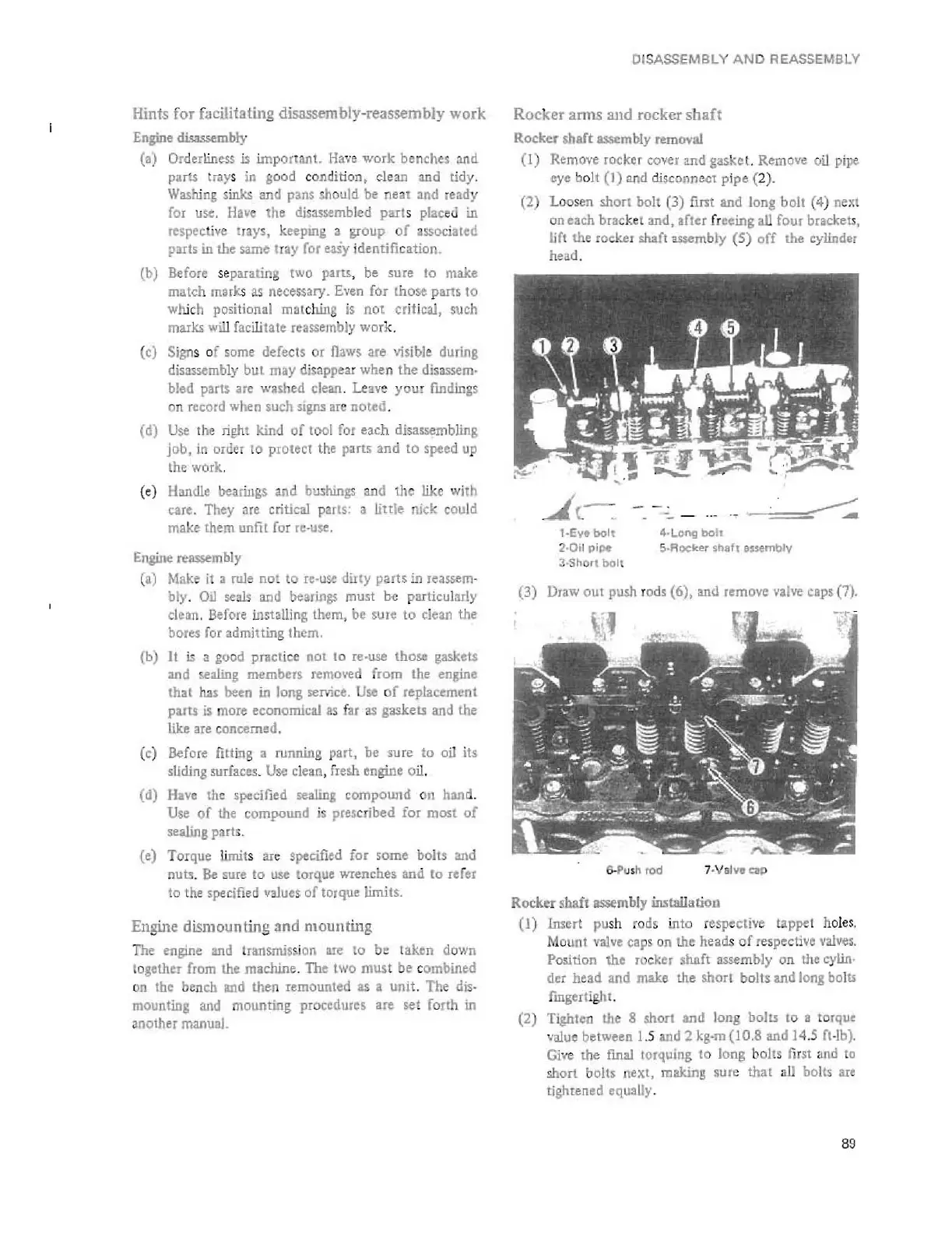

(1)

Remove

rocker

co

ve

r and gasko

t.

Remove

oil

pipe

eye bolt

(I)

and disconnecr

pipe

(2).

(2

) Loosen short bolt (3)

fi

rSt

and long bolt

(4

) n

ex

t

on

each

bra

cket

and.

after

fr

eeing

all

four

bracket

s,

~ft

the rocker shaft

.surnbly

(5)

off

the cylinder

head.

--

~

--

1·Sy.

bo

lt

2·0i

l pi

pe

3-5110rt

bol

t

4·Lor.g

boh

5·F\ock

e.r

s.hah e,:semblv

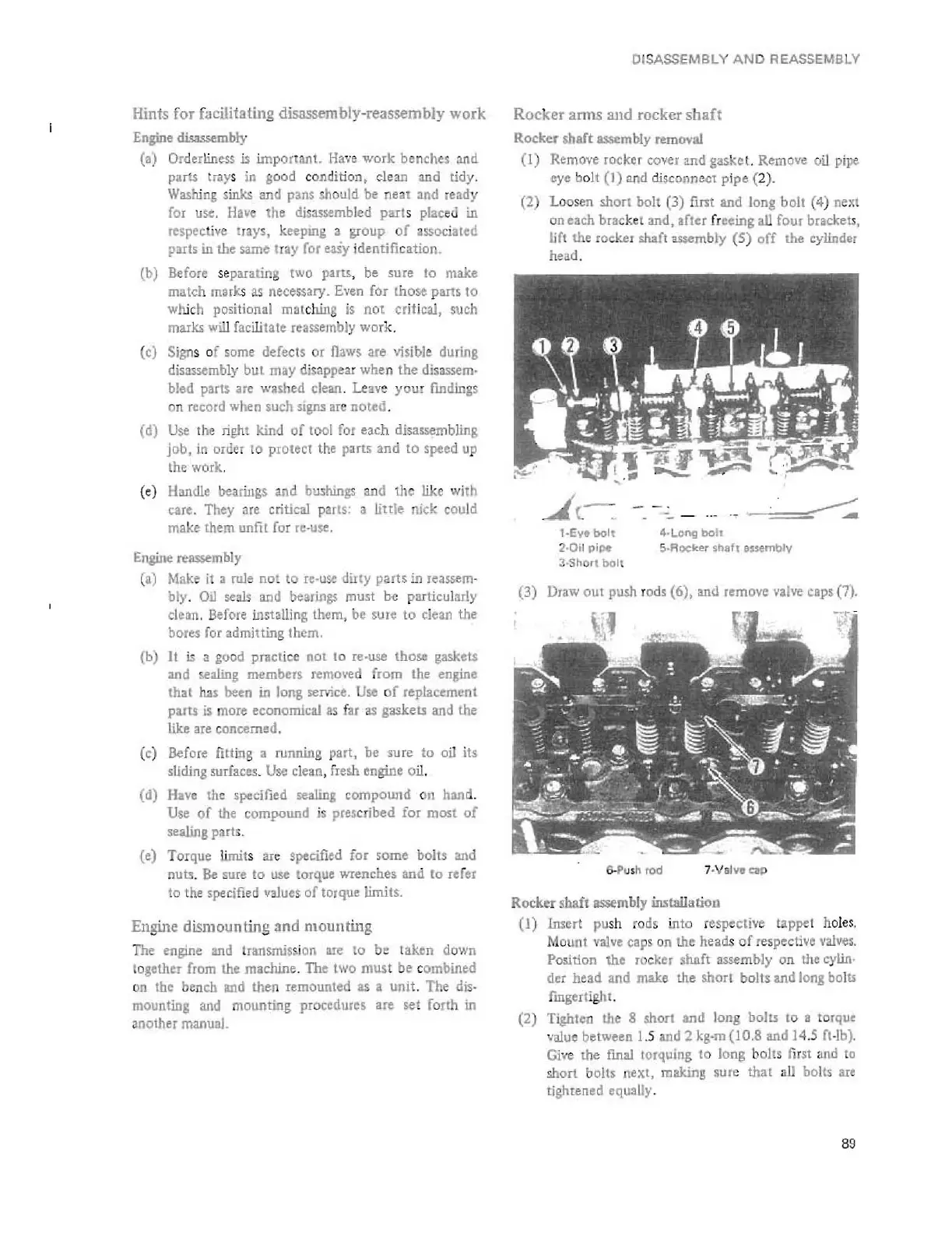

(3) Draw

out

push rods (6), and remove

valve

ceps (7).

6-Pu

sk

rod

7·Valve

t:zI

p

Rocker shafl assembly iru5ta1I.tion

(1) Insert push

ro

ds

into respective tap

pe

t h

oles.

Mou

nt

valve

cap

s on the heads

of

respective

"alves.

Positi

on

the

rocker

shaft

asse

mbly on

the

cylin.

der head and make the short bolts and long bol

ts

ing.rlight.

(2)

Tighten the 8 shorl and long bolts to • torque

value between 1

.5

and 2 kg.m

(l0

.8 and 14.5

rt

-lb).

Gi

ve

Ihe final torquing to long bohs

fi

rst

an

d to

short

bolt,

next, malting sure

that

all bolts

ar'

tightened equ,Uy.

89

Loading...

Loading...