Pre Start Inspection and Operation

3.4

4. Check all hydraulic hoses, lines, and ttings.

Hydraulic oil under pressure can penetrate body tissue causing serious injury and

possible death. When troubleshooting a hydraulic system for leaks, always use

cardboard or wood as a detector. DO NOT USE YOUR BARE HANDS. If you are

injected with hydraulic oil or any other uids, immediately seek treatment by a doctor

trained in the treatment of penetrating uid injuries.

• Visually inspect all of the hydraulic hoses, lines, and fittings for signs of damage, wear or

leaking.

• If any signs of damage are visible, do not operate the machine until repairs have been made.

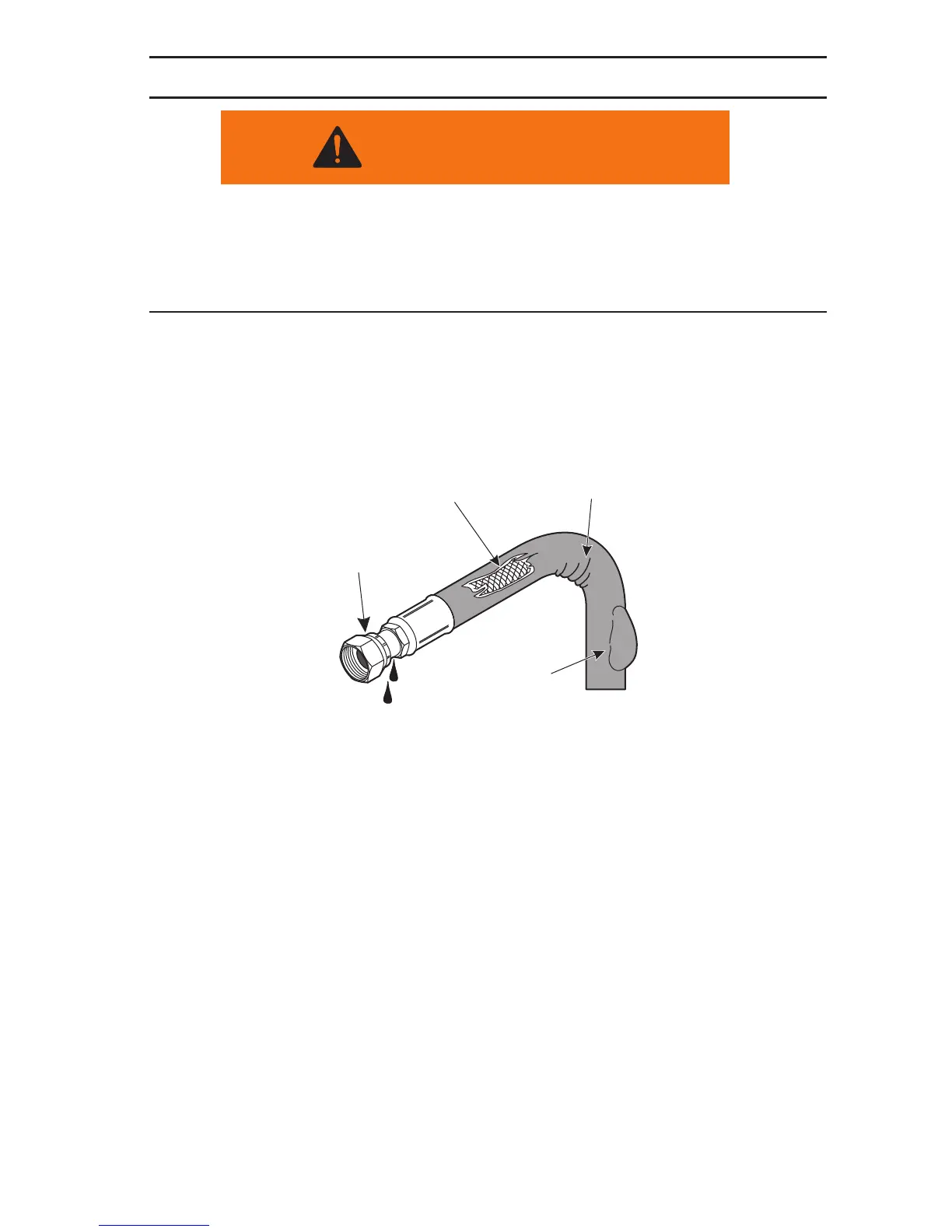

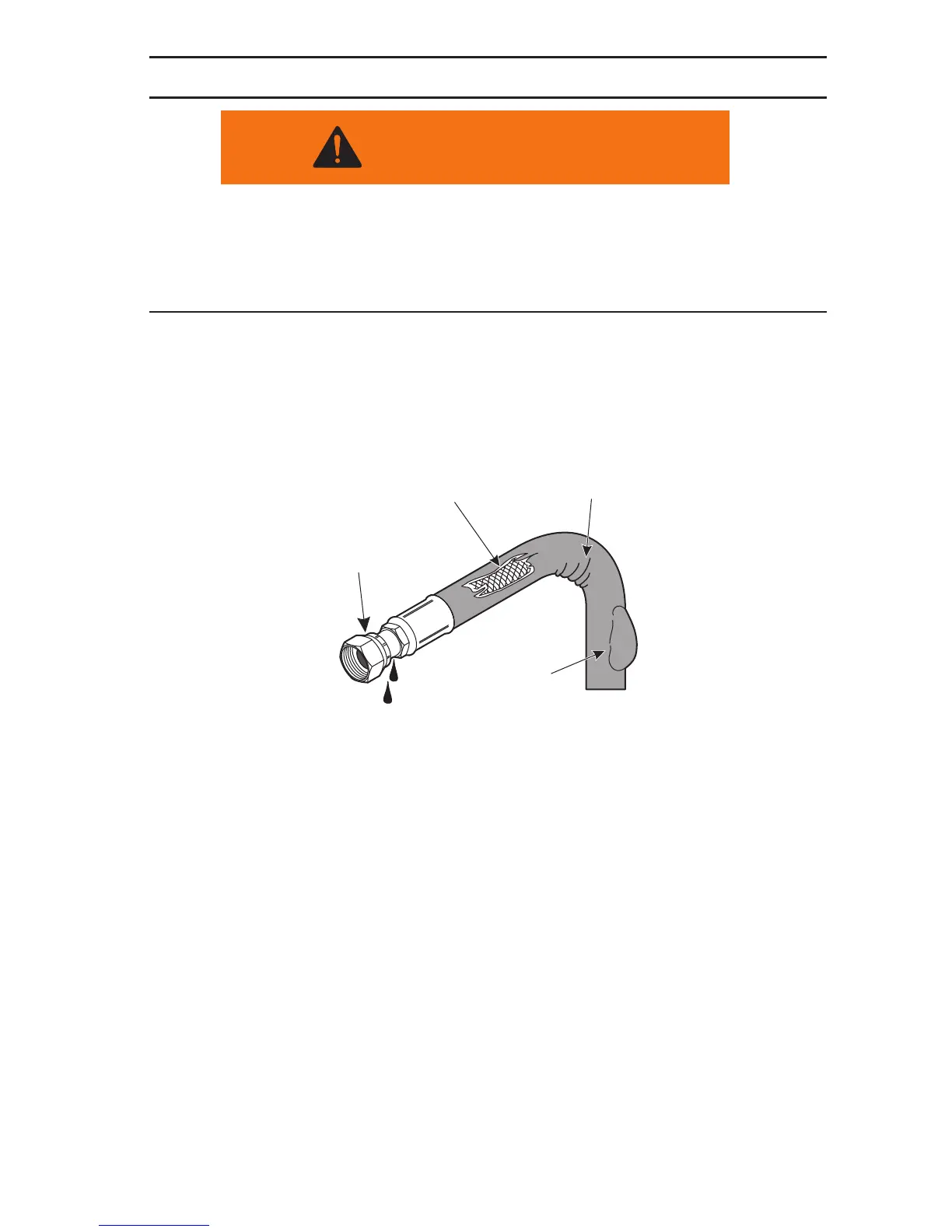

• Some examples of common hydraulic hose damage are shown in Figure 3–4.

Figure 3-4 Hydraulic Hose Damage

5. Check for loose or missing fasteners:

• Inspect for any loose or missing bolts.

• Tighten or replace any missing bolts immediately.

6. While you are performing the daily maintenance, inspect the machine for any signs of

damage, such as missing or damaged components, cracked welds, etc.

7. Check the track assemblies to make sure that:

• The tracks are in good condition and are not showing any signs of wear.

• Track tension is properly set.

• Track drive motors are not leaking oil or hydraulic uid.

1. End ttings damaged or leaking.

2. Outer covering chafed or cut, and wire reinforcing is exposed.

3. Hose shows signs of kinking or crushing.

4. Outer covering ballooning.

1

3

4

2

WARNING

Loading...

Loading...