205

ӏࡾጀ࣊ȟҋȽȗȻȠ

WHEN SUB-STANDARD MACHINING OCCURS

12 ӏࡾጀ࣊ȟҋȽȗȻȠ

WHEN SUB-STANDARD MACHINING OCCURS

12-1 ൡಽɁʶʣʵᝩ

Adjusting Machine Level

ൡಽటͶȾᩜȪȹɂǾʶʣʵȟᝩȨɟȹȗȽȗȦȻȟՁى

ȻȪȹᐎțɜɟɑȬǿ෩ໄبɥΈႊȪȹǾൡಽɁʶʣʵɗɀ

ȫɟȽȼɥᆬᝓȪɑȬǿ

If we consider the machine body, a reduction in machining

precision is caused primarily by incorrect machine level

adjustment. Using a level, measure the machine horizontal

level and degree of twisting.

1 ҝёૄᝢం 1 ቛ “ ʶʣʵɁᆬᝓᴬᝩ ” 1 Separate volume, INSTALLATION MANUAL Chapter 1

“ADJUSTING MACHINE LEVEL”

12-2 ʚʍɹʳʍʁɁᆬᝓ

Backlash Check

ӏࡾጀ࣊ȾɃɜȷȠȟȕɞکնȾɂǾʚʍɹʳʍʁɥᆬᝓȪ

ȹȢȳȨȗǿ

If machining accuracy varies substantially, confirm the machine

backlash.

ᴹႊȬɞɕɁᴻ <Necessary Tools>

• ȹȦࣻʊɮʮʵɼ˂ʂ •Lever type dial test indicators

• ʨɺʗʍʒʃʉʽʓ •Magnet stand

ᴹᬲᴻ <Procedure>

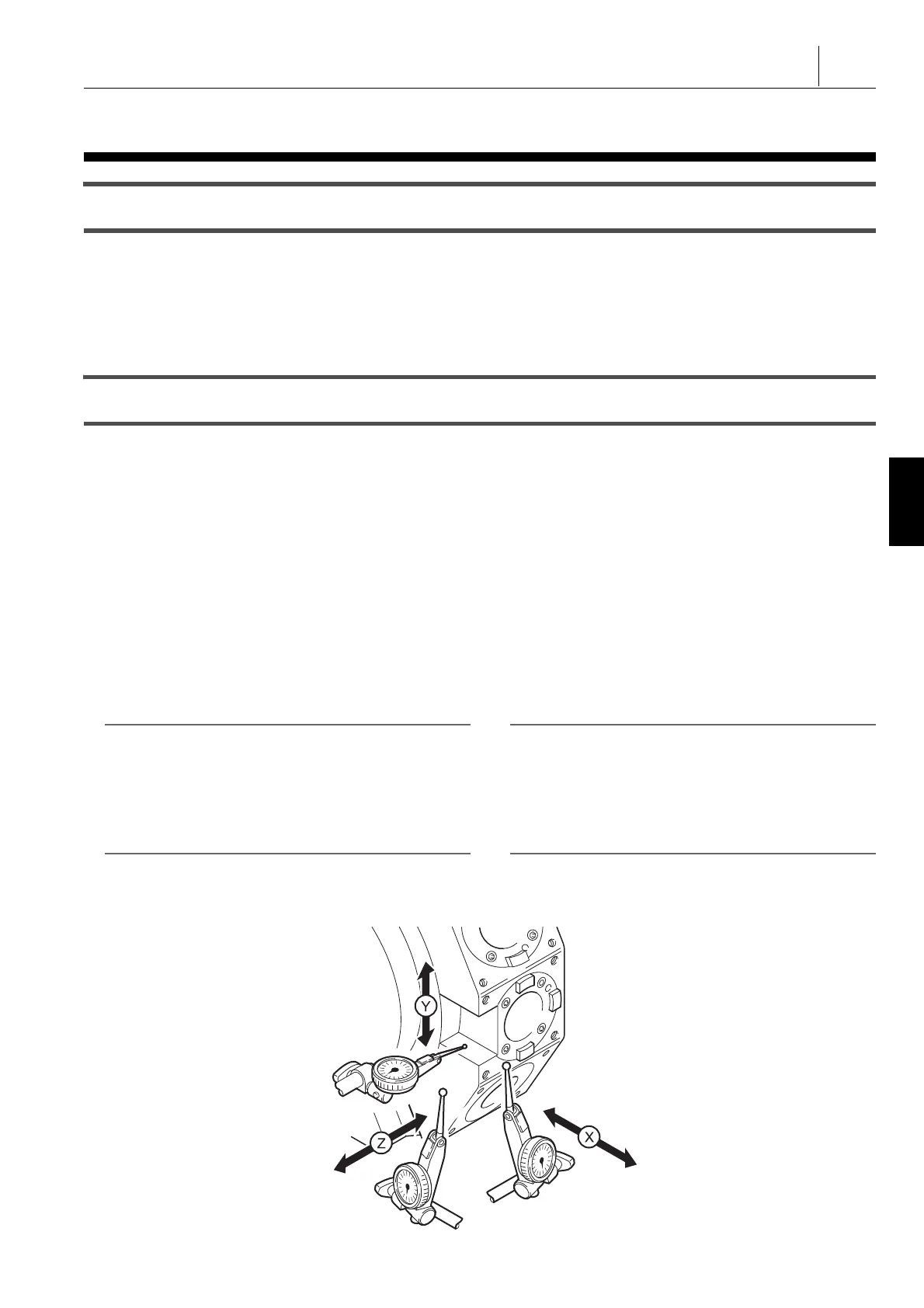

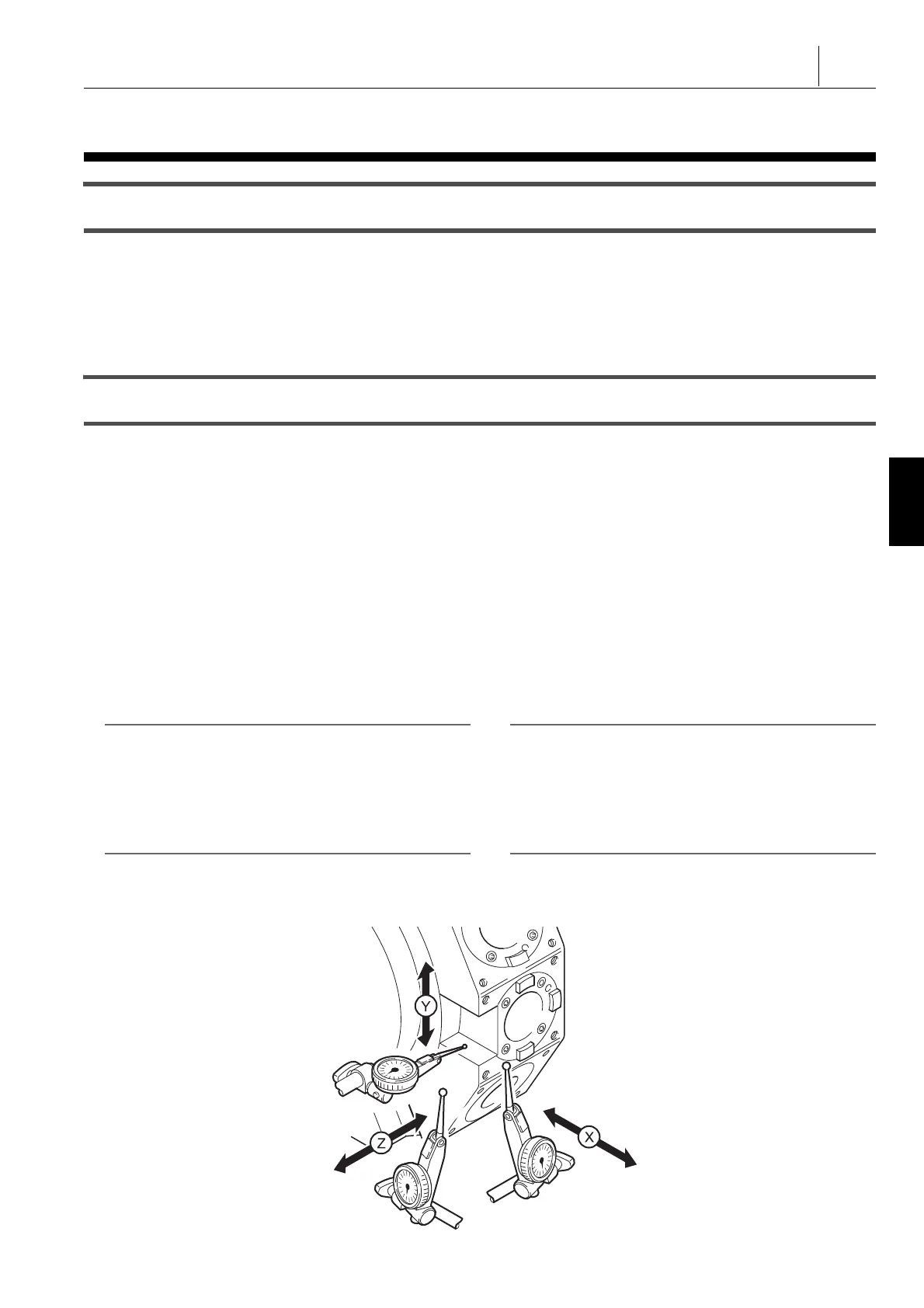

1) ʨɺʗʍʒʃʉʽʓɥΈႊȪȹǾȹȦࣻʊɮʮʵɼ˂ʂɥ

˿ᢉիȾɝȤɞǿ

1) Using a magnet stand, mount a lever type dial test

indicators on the spindle head.

2) ӦʛʵʃᄉႆبɥΈႊȪȹǾҏ࿎իɥ˿ᢉիɁᣋȢȾሉ

ӦȨȮɞǿ

2) Position the turret close to the spindle head using the

manual pulse generator.

3) ӦʛʵʃᄉႆبɥΈႊȪȹǾȹȦࣻʊɮʮʵɼ˂ʂɁ

ᦉɥᆬᝓȪȽȟɜǾ˩َɁɛșȾລްފɥລްͱᏚȾȹ

ɞǿ

3) While observing the lever type dial test indicators, rotate

the manual pulse generator until the gage stylus is aligned

with the measuring point as shown in the diagram below.

2 าᜤ 2 NOTE

ȹȦࣻʊɮʮʵɼ˂ʂɥລްኙȾ᜔ȨȮɞȻȠȾɂǾȭᣞ

ɝᦀᤣʃɮʍʋȺᣞɝᦀ 0.001 mmᴥ

Z

Ȑu1ȑᴦɥᤣȪȹȢȳ

Ȩȗǿ

When aligning the stylus on the lever type dial test indicators with

the measuring point, ensure the axis feed amount is set to

0.001 mm using the axis feed amount selection switch

Z

[u1].

4) ᦉȟጙ 1/4 وᢆȪȲȻȦɠȺӦʛʵʃᄉႆبɁوᢆɥ

ඨɔǾᄻᄱɝɥ “0” ȾᜫްȬɞǿ

4) Stop rotating the manual pulse generator when the stylus

turns 1/4 of a rotation and set the scale to “0”.

2 าᜤ 2 NOTE

ȹȦࣻʊɮʮʵɼ˂ʂȟەɟɞȝȰɟȟȕɞɁȺǾᦉȟᄻᄱɝ

ɥ 1 ֚˨وɜȽȗɛșǾาȪȹȢȳȨȗǿ

Tak e c ar e n ot t o rota te the sty lus on t he le ve r t yp e dia l t es t

indicators more than a single rotation to prevent damage to the

gage.

Loading...

Loading...