215

ӏࡾጀ࣊ȟҋȽȗȻȠ

WHEN SUB-STANDARD MACHINING OCCURS

2 าᜤ 2 NOTE

ȦɁȻȠǾȭɟɁᦀȟఊɕߴȨȢȽɞɛșȾ X ᢉɥӦʛʵʃᄉ

ႆبȺᝩȪȽȟɜͽഈɥᚐȶȹȢȳȨȗǿ

Perform X-axis adjustments using the manual pulse generator

during the above procedure to ensure deviation is reduced to the

minimum amount.

19) фᜏሰȠʦʵʒ 10 Ȟɥ፻ɔǾюɁȭɟᦀɥѓ࣊

ᆬᝓȬɞǿᛵȾȫȹǾᬲ 15) Ȼ 18) ɥᎱɝᣌȬǿ

19)Tighten the 10 hexagon socket head cap screws and

perform center-height deviation measurement. If

necessary, perform steps 15) and 18) again to readjust.

20) ϡᓸʞʽɁڋɔಃɥɝȤɞǿ 20)Replace the plug covering the eccentric pin.

21) ൡಽໃɥȪɖȬɞǿ 21) Turn OFF the main power.

22) ȹȦࣻʊɮʮʵɼ˂ʂȻผщɥɝ۶Ȭǿ 22)Remove the lever type dial test indicators from the

mounting jig.

23) ۶ȪȻᣡɁᬲȺǾҏ࿎իɁҰᬂɵʚ˂ȝɛɆϫᬂɵ

ʚ˂ɥɝȤɞǿ

23)Remount the turret front and side covers by following the

removal procedure in reverse.

24) ۶ȪȻᣡɁᬲȺǾҏ࿎իɁ֚ᣃɵʚ˂ᴥZ ᢉʡʷʐɹ

ʉȝɛɆɿʓʵϫᬂɵʚ˂ᴦɥɝȤɞǿ

24)Remount the turret surrounding covers (Z-axis protector

and saddle side cover) by following the removal procedure

in reverse.

25) ʫʽʐʔʽʃɵʚ˂ɥɝȤɞǿ 25) Remount the maintenance cover.

2 าᜤ 2 NOTE

ᝩǾᬲ 6) ȺขɔȲͱᏚɥ X ᢉɁژໄͱᏚȾᜫްȬɞᛵ

ȟȕɝɑȬɁȺǾࣷᇋɿ˂ʝʃᩌȾȧᣵፅȢȳȨȗǿ

Following adjustment, the point determined in step 6) must be set

in the parameters as the X-axis reference position. Contact the

Mori Seiki Service Department for assistance in performing this

procedure.

12-5 ઃիɁȭɟᝩ

Tailstock Center Adjustment

ʅʽʉӏࡾȺʹ˂ɹȟа܀ᴬаጯȾȽɞȻȠǾ˩ɁᬲȺ

ઃիɁȭɟɥᝩȪȹȢȳȨȗǿ

When primary taper or primary flare is generated on the

workpiece during center machining, adjust tailstock centering

according to the following procedure.

ᴹႊȬɞɕɁᴻ <Necessary Tools>

• ȹȦࣻʊɮʮʵɼ˂ʂ •Lever type dial test indicators

• ȹȦࣻʊɮʮʵɼ˂ʂȤผщ •Lever type dial test indicators mounting jig

• фᜏʶʽʋ •Hex wrench

• ʙʽʨ •Hammer

• ್ •Rod

ᴹᬲᴻ <Procedure>

1) X/Z ᢉᴥY ᢉറᴷX/Z/Y ᢉᴦɁՁཟ࢜ɥᚐșǿ 1) Perform a zero point return of the X- and Z-axes (Y-axis

specifications: X/Z/Y-axes).

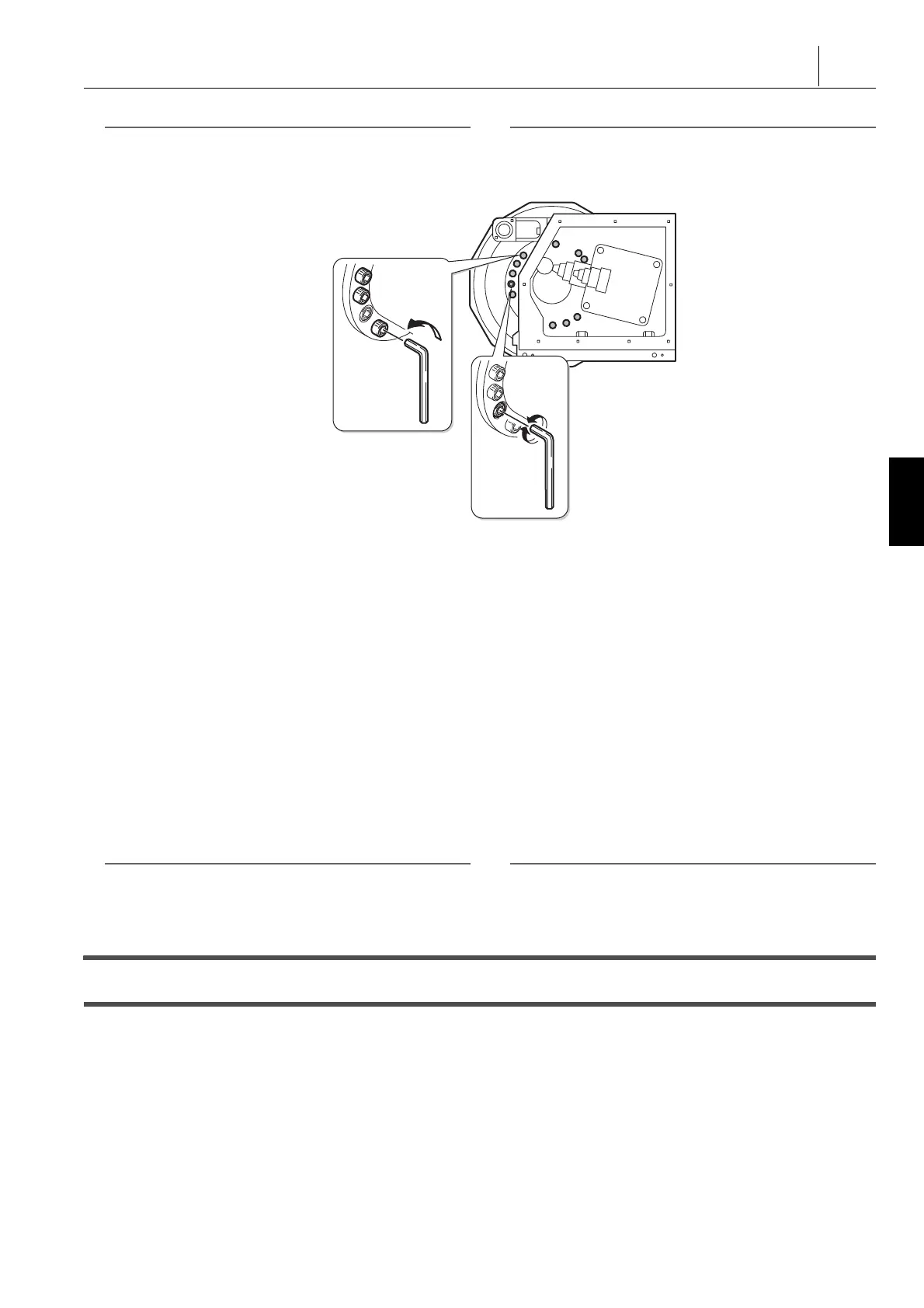

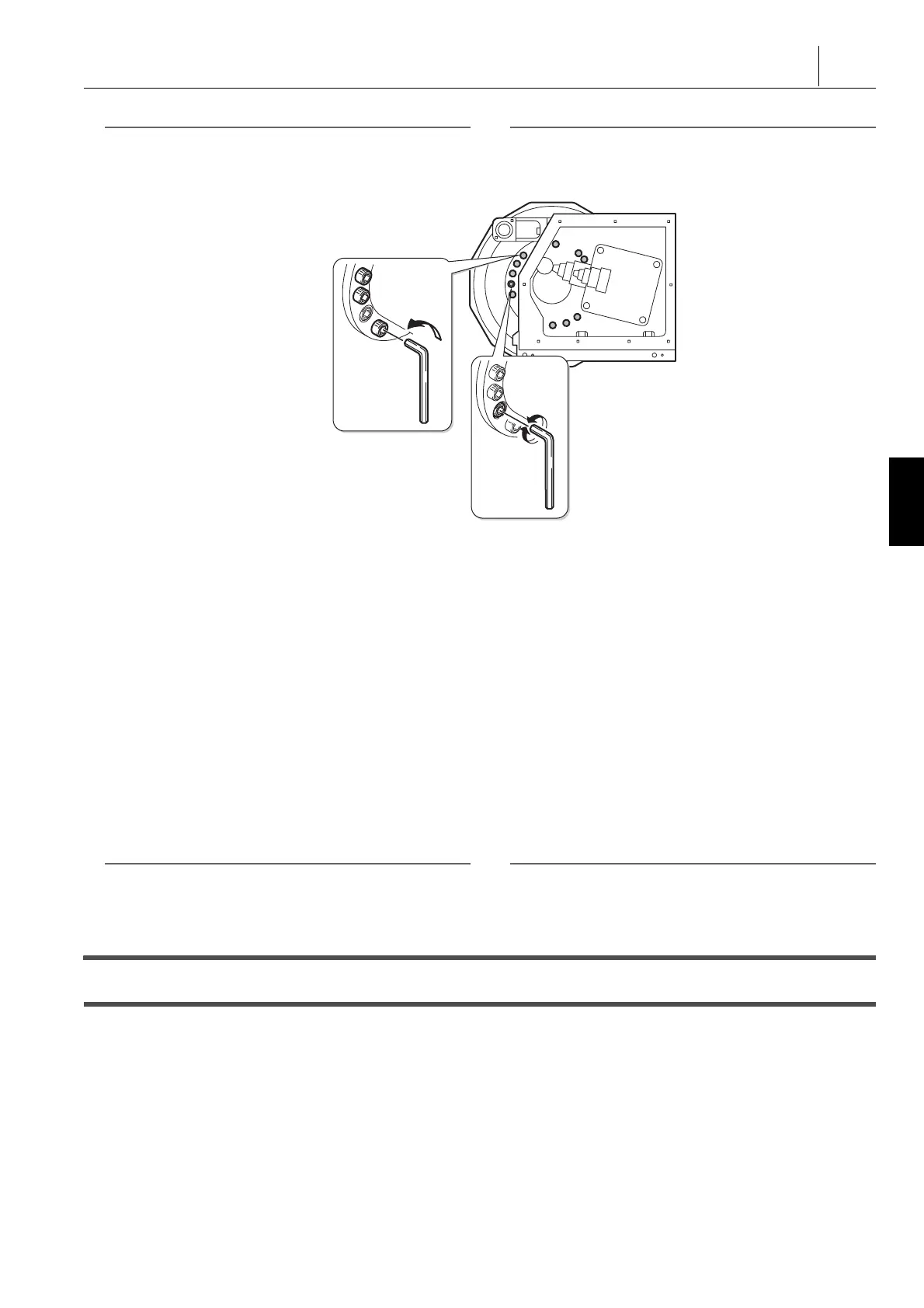

Cap Bolt Loosing (10)

Eccentric Pin Adjustment

ɷʭʍʡʦʵʒɁɔᴥ10 Ȟᴦ

ϡᓸʞʽɁᝩ

Loading...

Loading...