บ٢ʰʕʍʒ

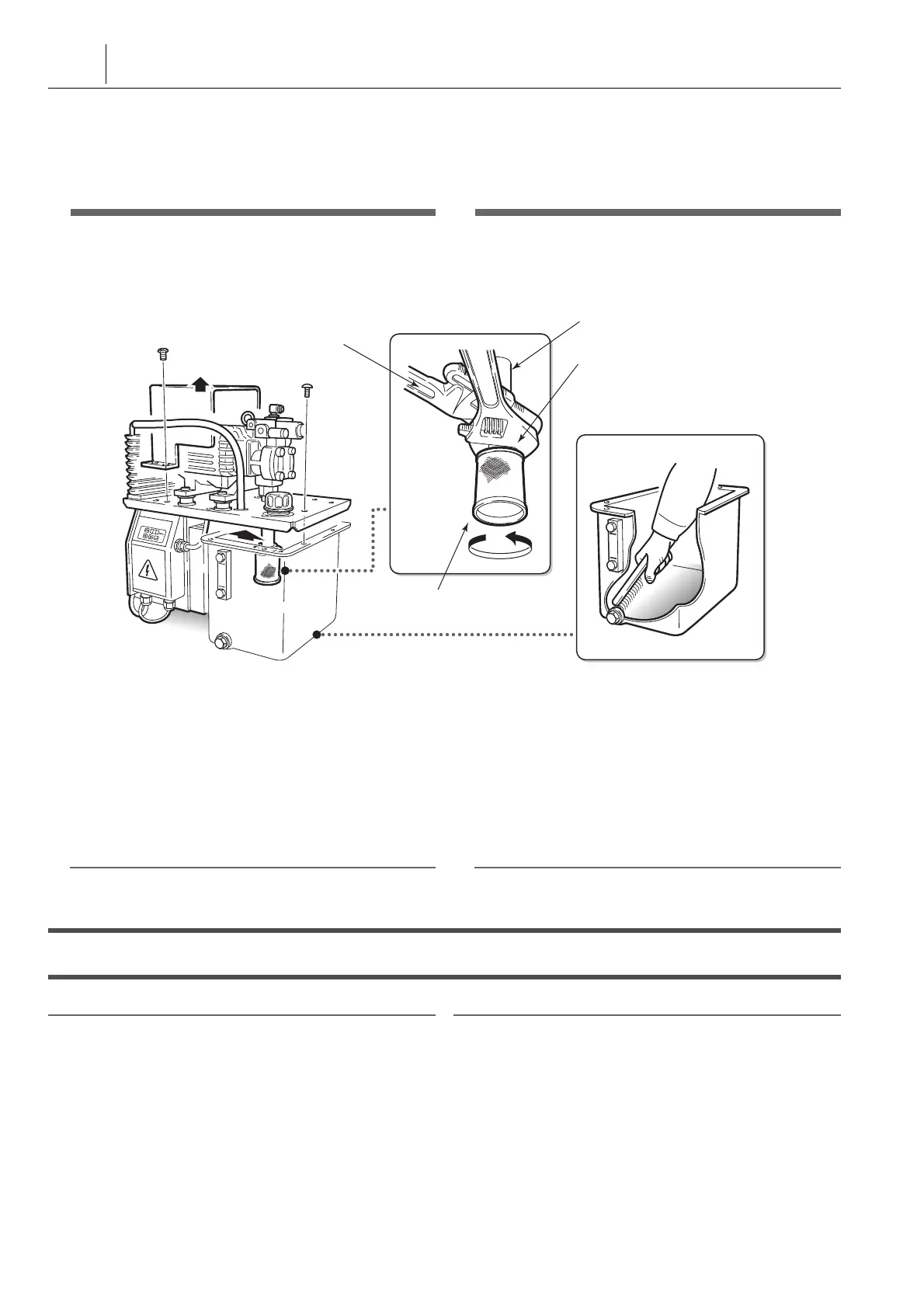

HYDRAULIC UNIT

98

d) ɒ˨ȥᥓከɁɀȫȾʁ˂ʵʐ˂ʡɥࢊȠǾɿɹ

ʁʱʽʃʒʶ˂ʔɥɝȤɞǿ

d) Apply sealing tape to the threaded section of the suction

pipe and reattach the suction strainer.

8) ʉʽɹюɥཌྷบȺຏોȬɞǿ 8) Clean the inside of the tank with kerosene.

7 า 7 CAUTION

ཌྷบɥΈႊȬɞȻȠɂǾٍ֚ȾཌȟȽȗȞᆬᝓȪǾԚґ

ɥȷȤȹȢȳȨȗǿ

Use caution when using kerosene, and make sure there

is no open flame in the vicinity.

9) ɂȤȽȼȺʓʶʽՠȾᅔȪȲɟɥɝȢǿ 9) Remove foreign matter from around the drain plug using a

brush.

10) ʉʽɹ˨ᬂɥɝȤɞǿ 10) Remount the tank upper plate.

11) บ٢ʰʕʍʒɥЫȼȝɝȾᜫᏚȬɞǿ 11) Remount the hydraulic unit on the machine.

12) ᥓከɥɝȤɞǿ 12) Connect the piping.

13) ፈบՠɷʭʍʡɥ۶Ȭǿ 13) Remove the fill port cap.

14) บᬂɥᆬᝓȪȽȟɜบɥᛃፈȬɞǿ 14) Supply oil while checking the oil level gage.

15) ൡಽໃɥоȬɞǿ 15)Turn ON the main power.

16) ʧʽʡɁ٢ӌȻоᬩɥᆬᝓȬɞǿ 16) Confirm pump pressure and suction noise are normal.

2 าᜤ 2 NOTE

оᬩȟ૰Ұɛɝ۾ȠȗȻȠɂบᦀɥѓᆬᝓȪȹȢȳȨȗǿ If the suction sound is louder than prior to oil replacement, check

the oil level again.

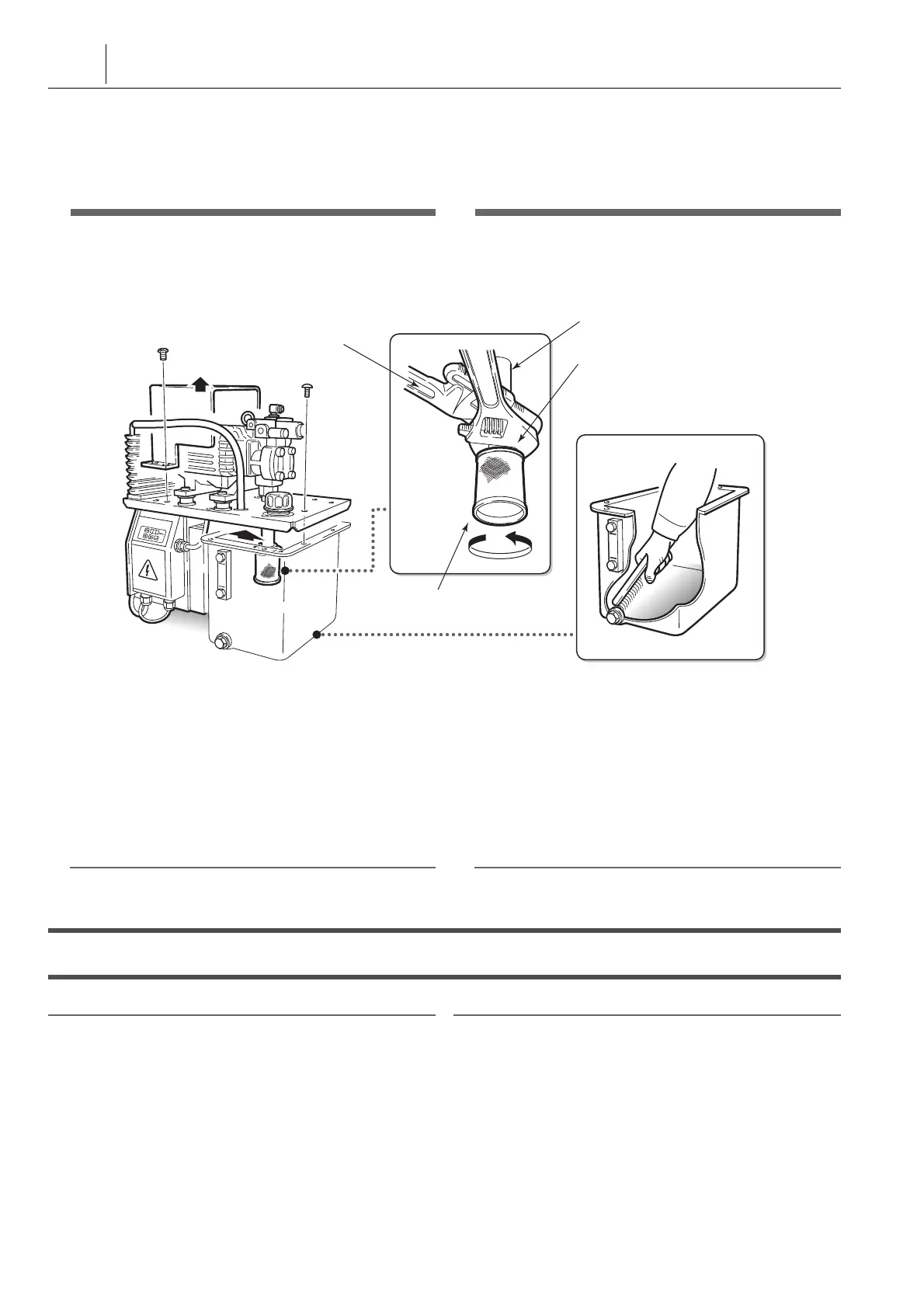

11-7 ʳɮʽʟɭʵʉɁʟɭʵʉɲʶʫʽʒɁ૰

Filter Element Replacement of Line Filter

2 าᜤ 2 NOTE

บ٢وᡅ˨ɁႱ࿎ɥՍȬɞȲɔȾʳɮʽʟɭʵʉɥɝȤȹȗɑ

Ȭǿ

The line filter is installed to remove foreign matter from the hydraulic

oil.

ʟɭʵʉȟᄻᝇɑɝɥᠭȦȬȻǾʟɭʵʉɲʶʫʽʒɁоɝՠȻҋՠ

Ɂࢃ٢ȺʚɮʛʃوᡅȟᩒȠǾͽӦบȟʟɭʵʉɲʶʫʽʒɥᣮᤈȺ

ȠɑȮɦǿͽӦบȾຉպȪȲ˪ጠ࿎ȟՍȺȠȽȢȽɝɑȬɁȺǾ˩

ᜤᬲȾȶȹʟɭʵʉɲʶʫʽʒɥ૰ȪȹȢȳȨȗǿ

If the filter is clogged, hydraulic oil cannot pass through the filter

element, as the by-pass opens due to the differential pressure between

the entrance and exit of the filter element. The foreign matter in the

hydraulic oil cannot be removed if this happens. Replace the filter

element by following the procedure given below.

ᴹ૰֚ఙᴻ <Replacement Interval>

1 ࢳȧȻ Once a year

u4

u8

Pipe Wrench

Suction Strainer

Suction Pipe

Monkey Wrench

ʛɮʡʶʽʋ

ɿɹʁʱʽʃʒʶ˂ʔ

ɒ˨ȥᥓከ

ʬʽɷ˂ʶʽʋ

Loading...

Loading...