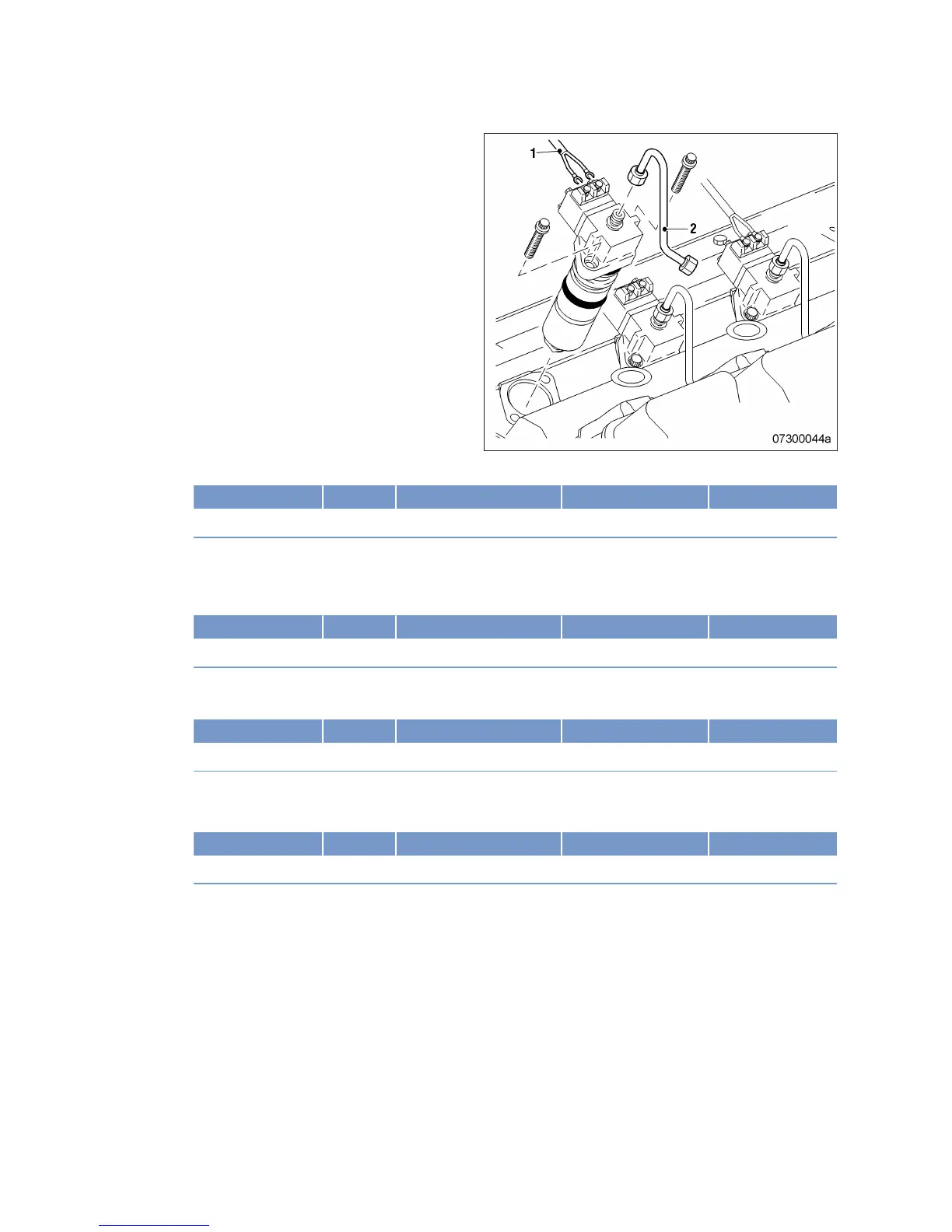

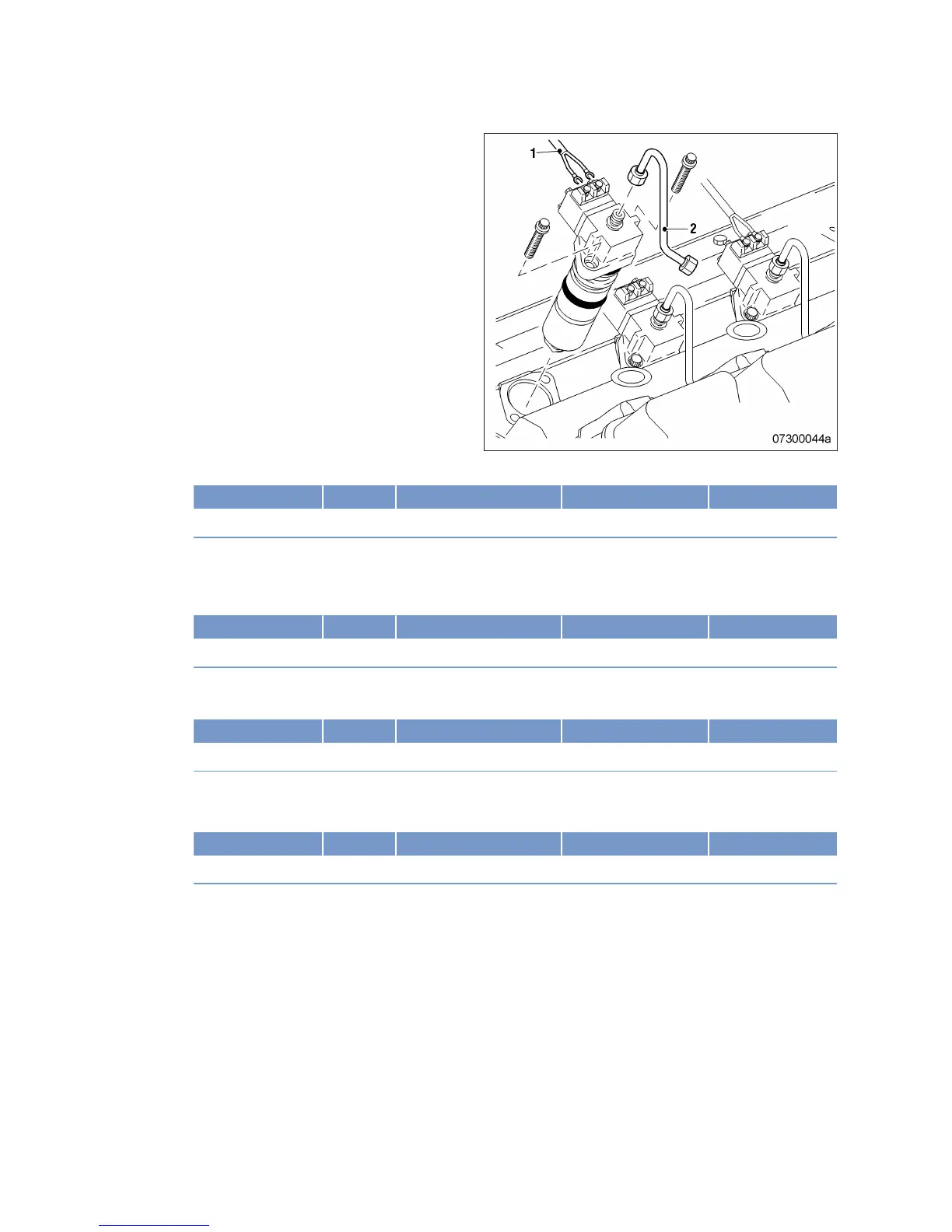

8. Install injection pump, observing marked in‐

stallation position.

9. Install securing screws of injection pump and tighten with torque wrench to the specified torque.

Name Size Type Lubricant Value/Standard

Securing screw Tightening torque 60 Nm + 12 Nm

10. Install fuel line (2).

11. Tighten union nut on the injection pump to the specified tightening torque using a torque wrench.

• Maximum permissible tightening torque: 35 Nm

Name Size Type Lubricant Value/Standard

Union nut Tightening torque 20 Nm + 5 Nm

12. Tighten union nut on the pressure pipe neck to the specified tightening torque using a torque wrench.

• Maximum permissible tightening torque: 35 Nm

Name Size Type Lubricant Value/Standard

Union nut Tightening torque 20 Nm + 5 Nm

13. Install injection pump wiring (1).

14. Use torque wrench to tighten screws to the specified tightening torque.

Name Size Type Lubricant Value/Standard

Screw Tightening torque 1.0 Nm ± 0.2 Nm

Final steps

1. Remove barring device (→ Page 166).

2. Clean mating faces on cylinder head and charge-air manifold.

3. Check gaskets for damage and replace them, if required.

4. Coat gaskets with grease (Kluthe Hakuform 30-10/emulsifier) and place onto cylinder head.

5. Install charge-air pipes.

6. Install engine control system (→ Page 240).

7. Open fuel supply line before fuel filter.

8. Vent fuel system (→ Page 193).

182 | Task Description | MW15550/06E 2012-02

TIM-ID: 0000004579 - 003

Loading...

Loading...