Language: English (EN) - Original operating manual

Order number: C100-P-WO-0000017.16-EN-ER

Instruction manual

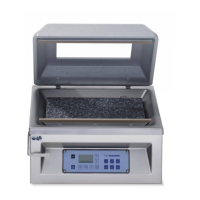

Chamber machine C100

MC06

Serial number:

.........................................................

Service address: Manufacturer:

MULTIVAC

Sepp Haggenmüller GmbH & Co. KG

Bahnhofstraße 4

D-87787 Wolfertschwenden, Germany

Tel.: 0049 8334 601 0

www.multivac.com

Date: 13.05.2014

The reproduction, distribution and utilization of this document as well as the communication of its contents to others without express authorization is

prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.