2205B0JE-DA-J-N_2014.05.

6 Troubleshooting

Screw Compressor J-series

6-8

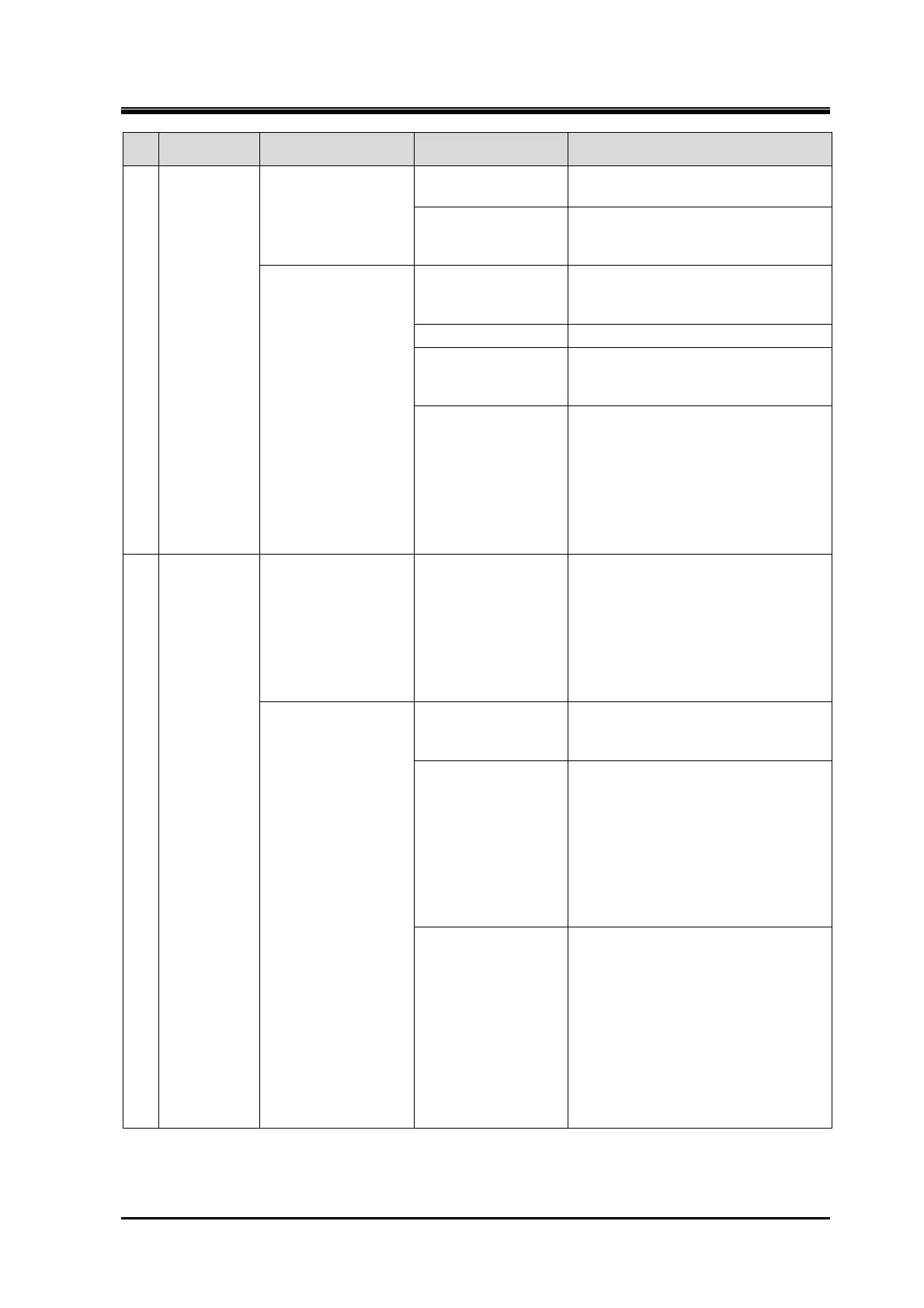

Trouble Direct causes Factors Actions

10 Capacity

control

malfunction

Capacity control

hydraulic line defect

Maladjustment of oil

controller valve

Readjust it.

Leak and clogging

in solenoid valve

gland and oil pipes

Remove factors. Check oil

contamination level and replace oil

as necessary.

Unloader piston not

moving (This is one

factor of a defect of

the capacity control

hydraulic line, but

described

separately.)

Damaged cap seal

for unloader piston

Check oil contamination level and

replace oil as necessary.

Replace O-ring, cap seal, etc.

Pinched cap seal Replace O-ring, cap seal, etc.

Worn cap seal Check oil contamination level and

replace oil as necessary.

Replace O-ring, cap seal, etc.

Refrigerant gas

retention in

unloader cylinder

Stop compressor. Operate oil pump

and repeat loading and unloading to

purge refrigerant gas from cylinder.

For liquid backflow operation,

remove the causes.

For malfunction of oil heater and

other devices on control circuit,

replace them.

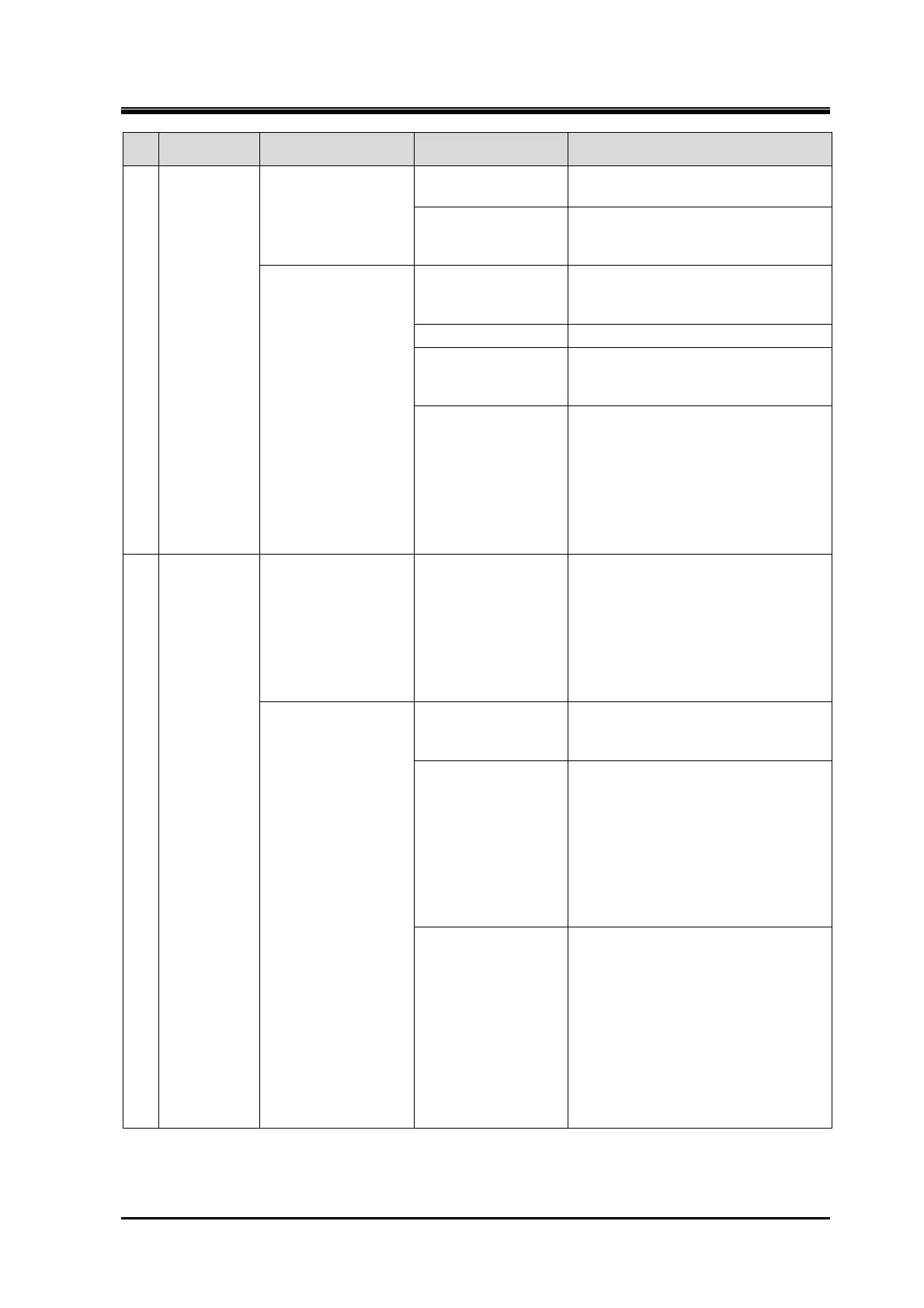

11

Abnormal

vibration

and/or

noise of

compressor

Insufficient axis

adjustment with

motor side

If vibration value is

higher in the axial

direction, this might

be the cause.

Readjust the shaft-center.

If abnormal vibration and noise fre-

quently occur in monocock unit, hot

alignment (perform rated operation

of compressor once to increase its

temperature and readjust before the

temperature decreases) is recom-

mended.

Large runout in

Male rotor axis

Uneven tightening

for thrust bearing

glands

If loose locknuts exist and no other

fault is found in parts such as thrust

bearing, tighten locknuts evenly.

Loose thrust

bearing

Forgetting to bend lock washer claw

or wear of thrust bearing rolling

element (ball) can be considered.

→Check for any defects in thrust

bearings. If there are any defects,

replace it. Then perform end

clearance adjustment as well as

axis contact check, and

reassemble it.

Imprecision in

dynamic balance of

rotors

Inspection only at site is impossible.

However, if no other causes for

abnormal vibration are found, and if

on-site overhaul has been

repeatedly performed, this might be

the factor.

Overhaul compressor at an

institution such at MAYEKAWA

Moriya Factory with dynamic

balance measurement/ adjustment

equipment.

Loading...

Loading...