6-6

[B] Defective AR-film standards

1. Test conditions

1) Place the bulb on the test table and light it with the white fluorescent lamp from the above.

2) Illuminance on the surface of the bulb tube shall be more than 1000 Lx, less than 1500 Lx.

3) Observe at a 40cm distance from tube surface, ignore the defects that can not be seen at this distance.

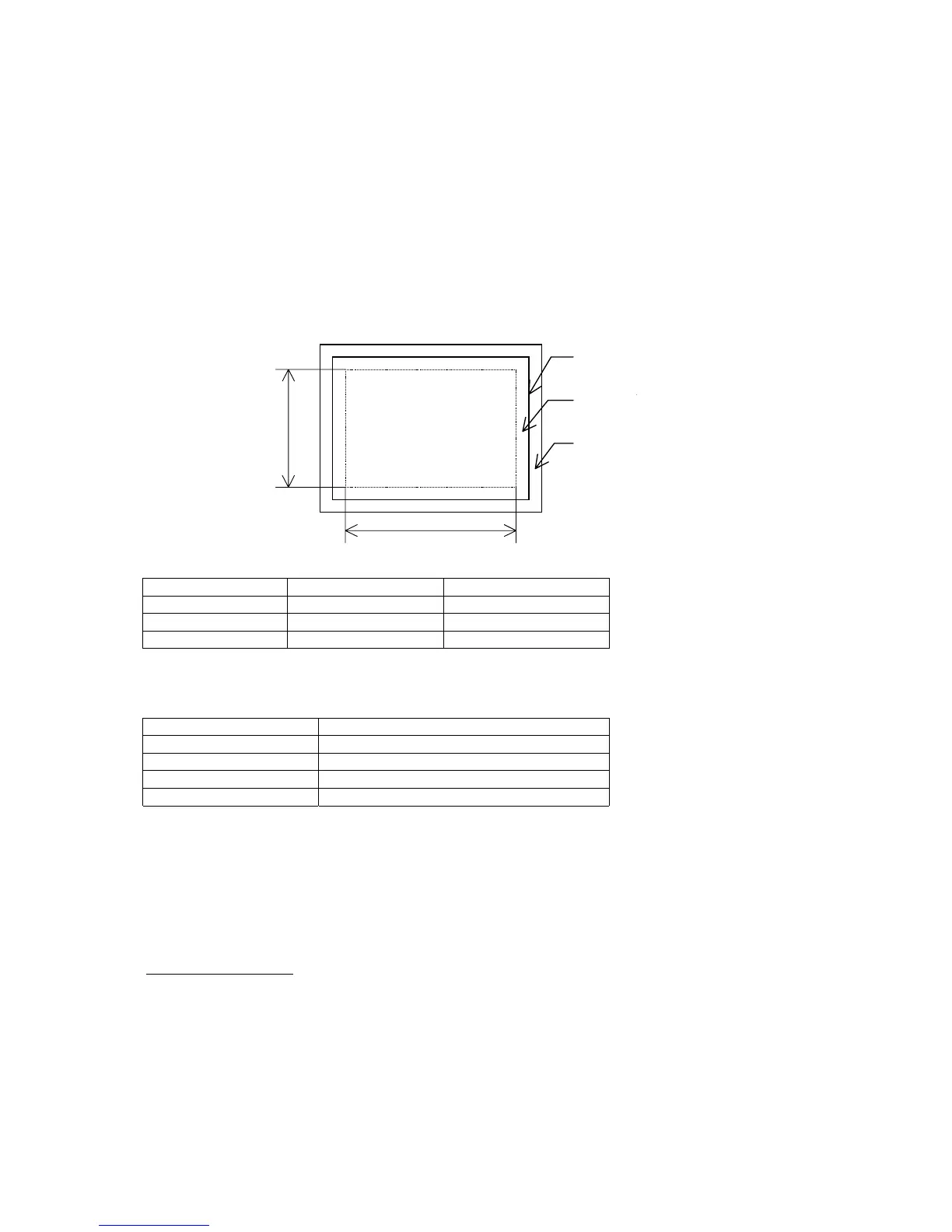

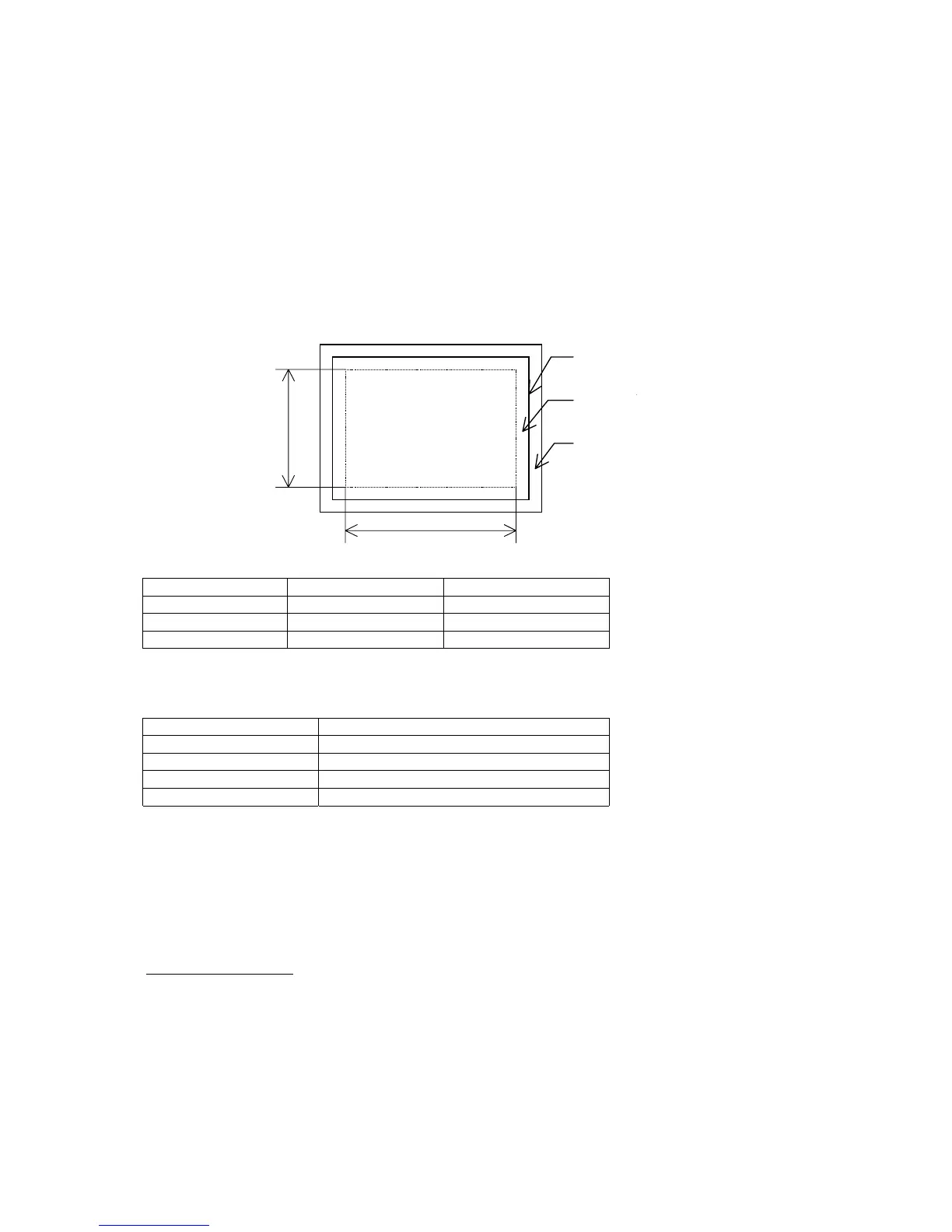

2. Zone classification

Zone A: Internal rectangular area with the horizontal and vertical dimensions shown in the following fig. In

which the screen center is located in the middle.

Zone B: Area between the edge of Zone A and phosphor screen.

Zone C: Area outside the edge of phosphor screen.

zone A

x

y

Edge of phosphor screen

zone B

zone C

Dimension table Unit = mm

Size X Y

41cm 300 225

46cm 360 270

51cm 395 295

3. Defect standards

3-1. Scratch (Glass and coating)

Width Zone A + B

More than 0.16mm Not acceptable

0.11 ~ 0.15mm Length within 13mm

0.06 ~ 0.10mm Length within 26mm

Less than 0.05mm No limitation of length

(Note 1) In the case that it has very law contrast, regard it as a stain, not as a scratch and apply the ratings in the

3-2. even if the scratch7s width is in excess of 0.16mm.

(Note 2) There is no specified standards regarding Z one C. However, no defect is acceptable that damages the

quality of the product. Discuss regarding the limitation, if necessary.

3-2. Opacity such as stain, etc. and peeling of coating

Defect contrast shall be classified. And judge defects in each contrast classification, according to size.

Definition of contrast

• High contrast: foreign object that blocks off the light from the phosphor screen, such as graphite

and dust, etc.

• Middle contrast: Translucent foreign object and stain (Ex. Solidified coating materials and white

stains, etc.)

Loading...

Loading...