u

Fig. 43

occupies a position other than those described above, then

loosen first the two screws " E " of the worm gear " F " (Fig, 45),

hold the balance wheel firmly, thus keeping the needle bar in its

highest position, and, by hand, turn the worm gear " F " around

the upper shaft until the eccentric " A " is in position I or position

II (Fig. 42).

After this adjustment firmly tighten the two screws " E " (Fig.

45).

The timing of the zig-zag movement and the movement of the

needle bar can also be performed with the aid of the gauge

10-4.

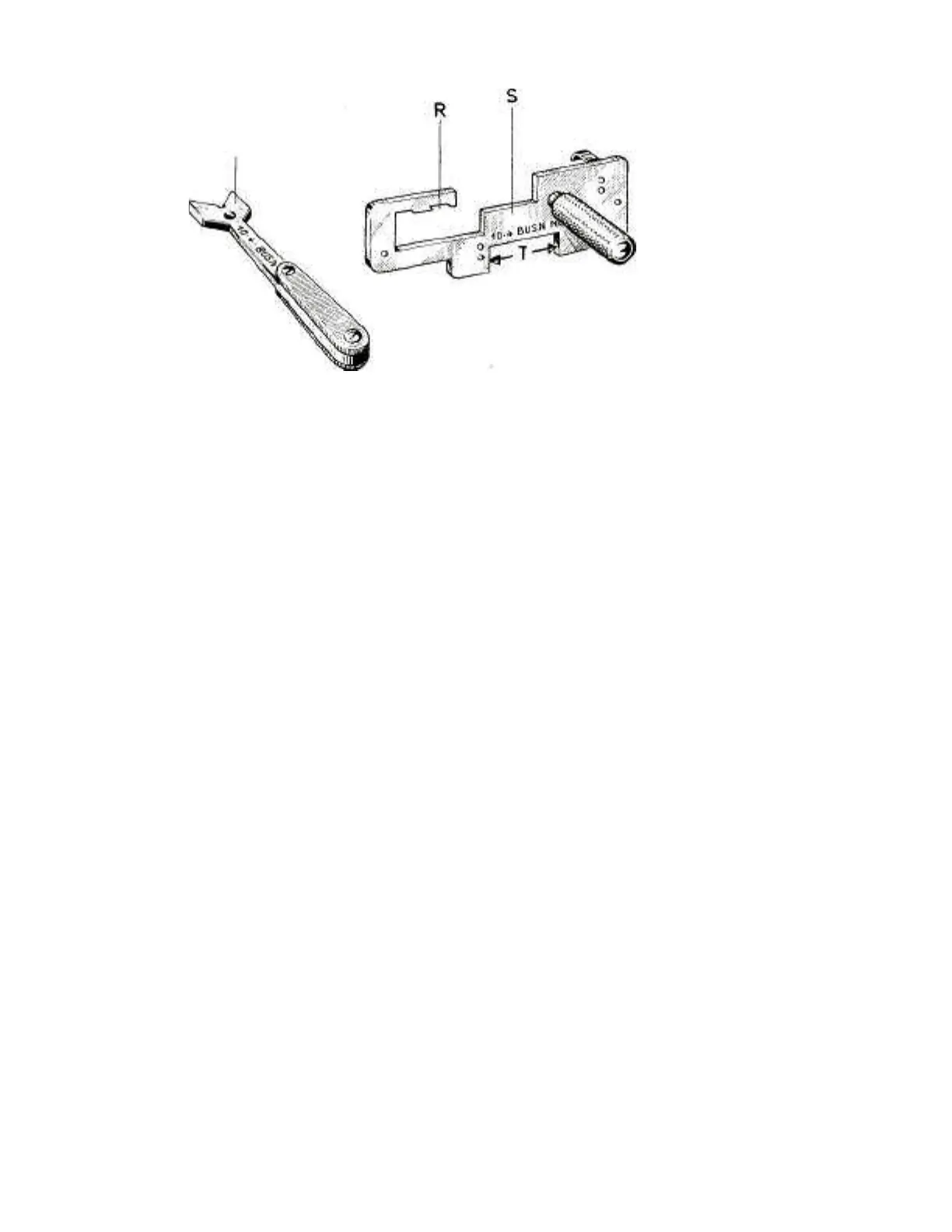

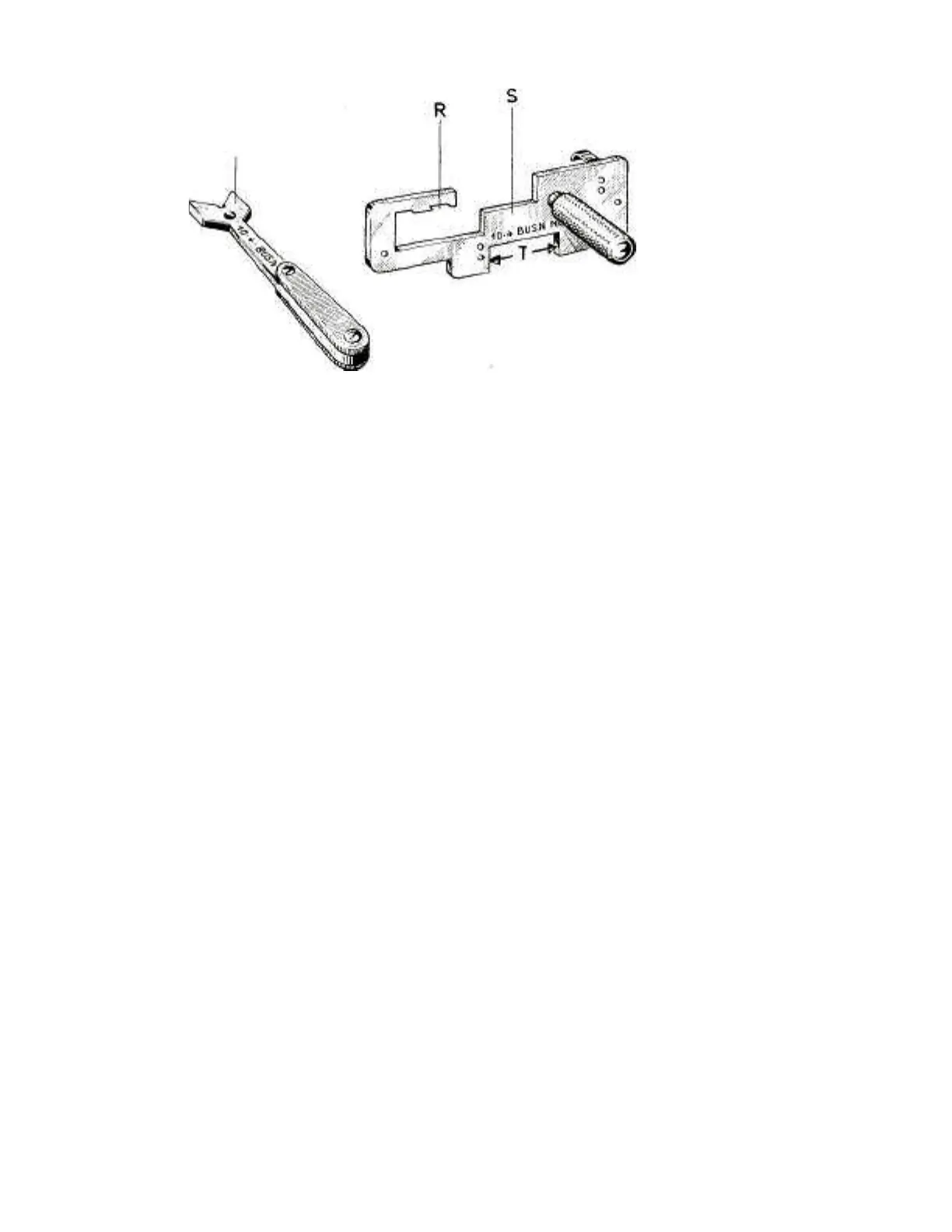

The gauge 10-4, shown in Fig. 43, consists of:

A plate " S " with a knurled stud serving as a holder.

During the timing operation this plate " S " replaces the zig-zag

mechanism cover plate. The notch " R " serves for positioning

of the needle positioning lever and the space " T " is required for

the zig-zag width lever.

A small steel plate " U ", with a handle-shaped portion at one end

and a V-shaped cut-out at the other end.

Loading...

Loading...