g)

The bearing bushing " E " of the lever assembly must be set

down on washer " 14 " and retaining ring " 11B " without force.

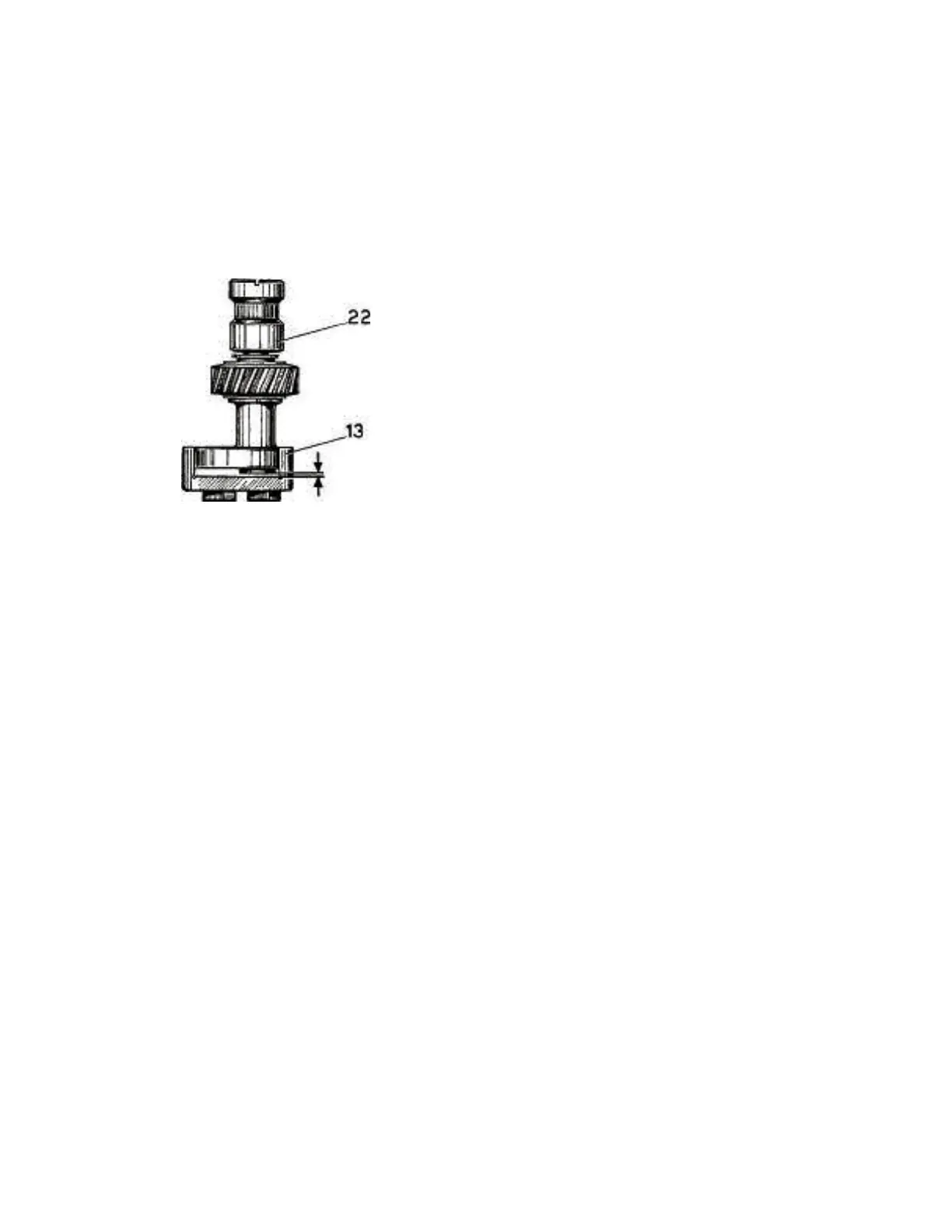

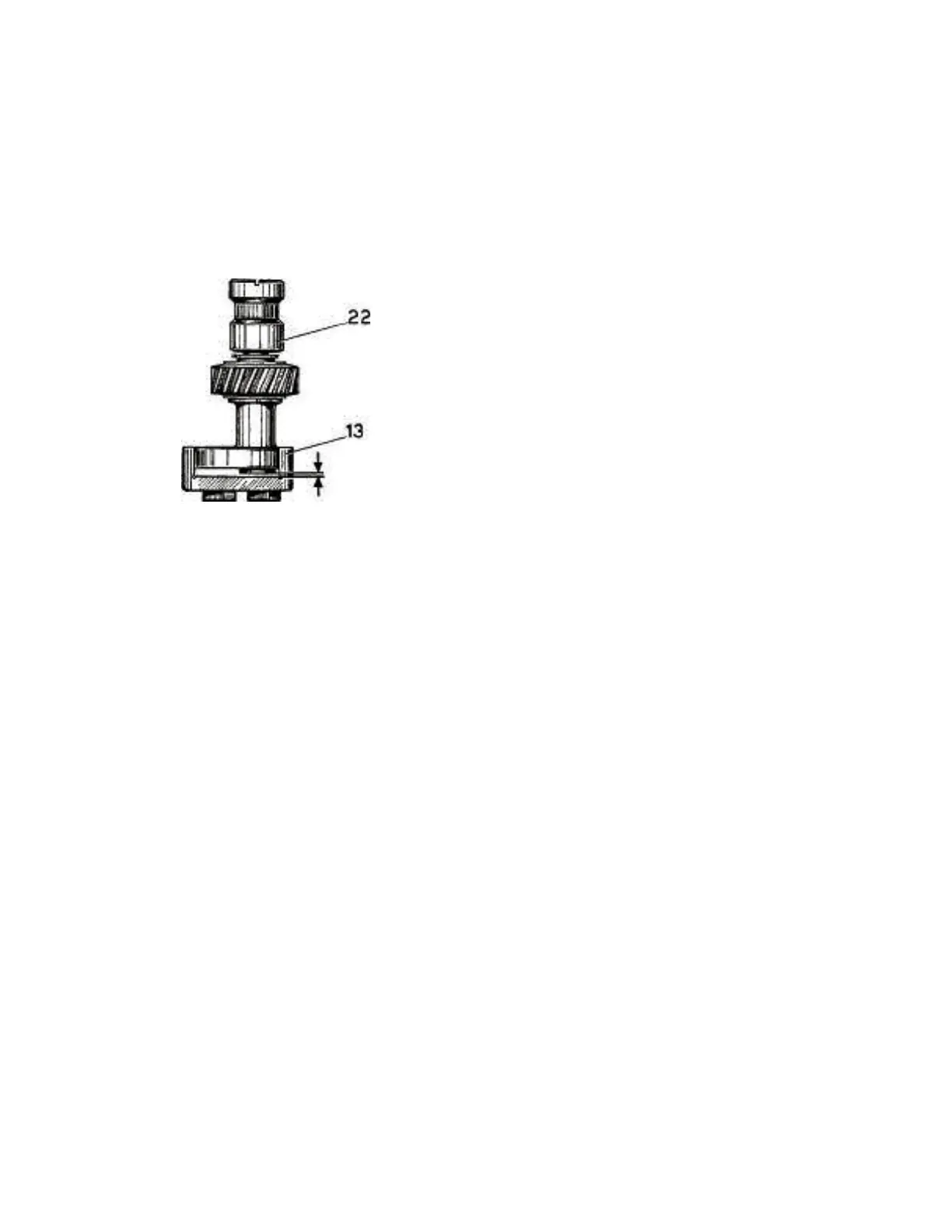

Adjust the clearance (open distance) between the underside

of the eccentric " 22 " (see Fig. 50) and the channel of the

lever assembly " 13 " so that there is a free space of about

0,02" (see Fig. 51).

about 0,02"

Fig. 51

h) Tighten securely screw " 2 " which holds pin " 15 " in the

hole of the upper arm (Fig. 50).

Place the sector " 21 " (Fig. 46) on the short stud in the link " 35

" of the vertical shaft, then let the sector " 21 " move into the

groove underneath the lever assembly " 13 ".

/') Take the needle bar positioning lever » " 12 " (Figs. 46 and 47)

and introduce it between the upper shaft and the rear wall of the

machine in such a manner that its handle " C " passes below

the upper shaft and through the front opening of the

machine (Fig. 47). The lever bearing " D " of this same lever

assembly " 12 " must be slipped over the pin " 15 ".

Slip retaining ring " 11A " into the upper groove of the pin " 15". 1)

Attach spring " 10 " (Fig. 52). m) Attach spring " 30 " (Fig. 52).

n) Replace the needle bar positioning rod " 7 " (Fig. 46) from

the face plate side of the machine and insert its right-hand end

into the hole of the block " 27 ". Connect this rod " 7 " with a

needle

Loading...

Loading...