1= b

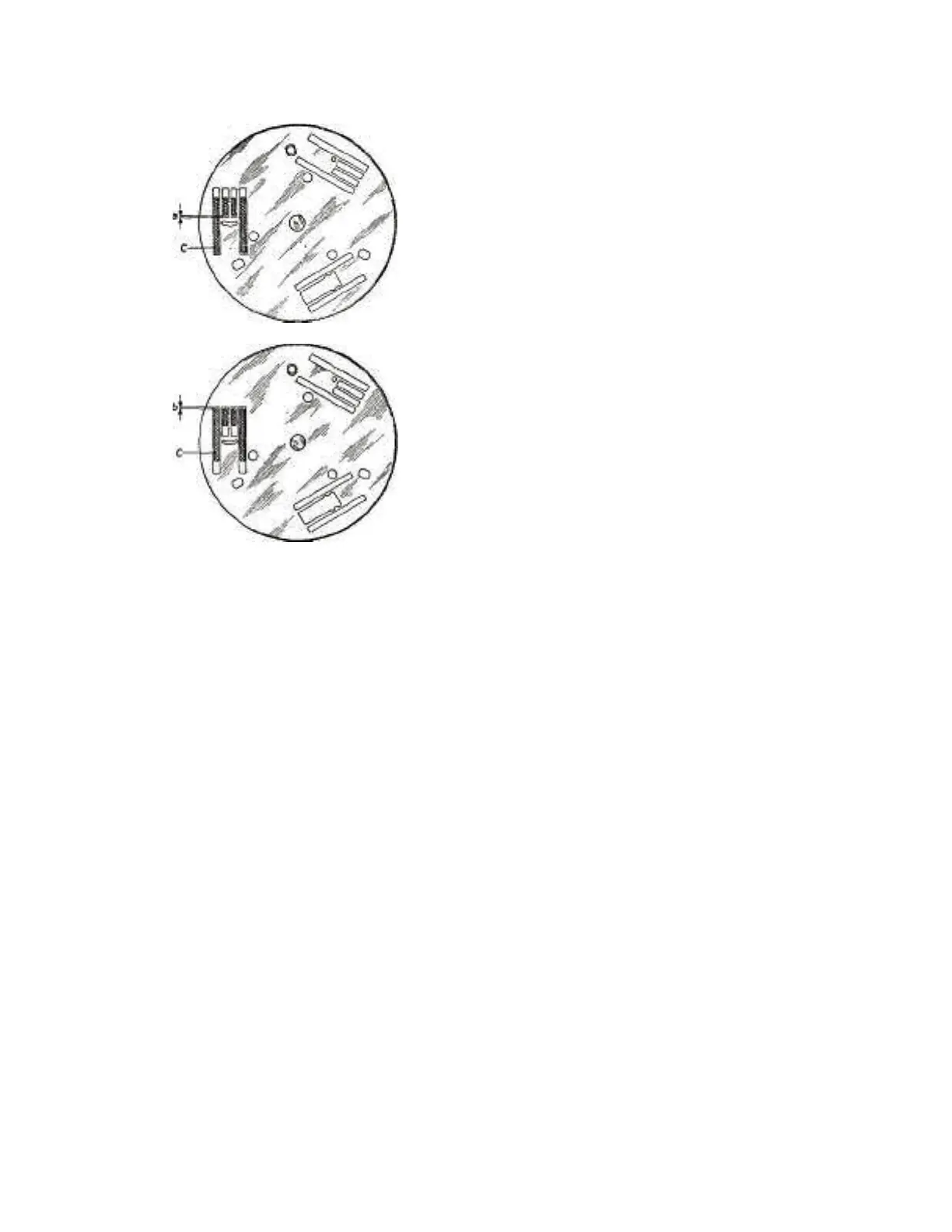

The feed dog has completed its

horizontal movement in the slot of

the needle

Fig. 59

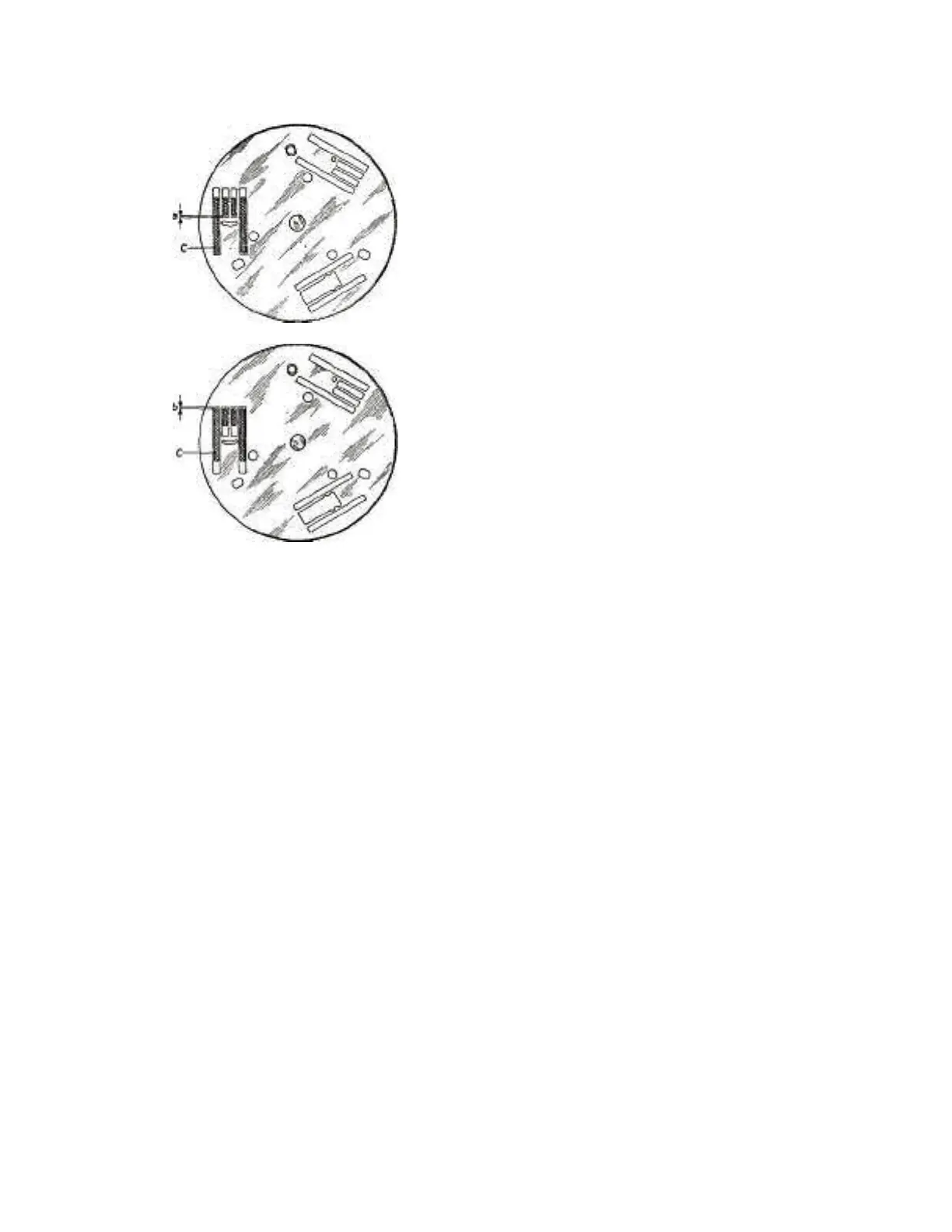

The feed dog starts its horizontal

movement in the slot of the needle

plate

Fig. 58

" G " until the rows of the feed dog are in the right position,

namely at the same distance from both edges of the slot.

Tighten screws " E " firmly, making certain that no looseness exists

between the pointed pins " F " and the feed rock shaft " G ". Before

tightening the screw " H", check adjustment " B" as

explained later on.

2nd Case

The rows "C" of the feed dog (Fig. 57) are not parallel with the

edges of the needle plate slots. To adjust, proceed as follows:

remove needle plate (as shown in Fig. 5) and slightly loosen the

screws " M " (Fig. 60) which fasten the feed dog to its support.

Then align the feed dog " C " as required and set it in the correct

position. Place the needle plate in its receptacle and check

whether the feed dog is parallel with the slots. Remove needle

plate again and tighten the screws " M ' firmly.

Adjustment " B "

If this adjustment is required, loosen the screw " H " which holds

the crank " L " to the feed rock shaft " G " (Fig. 60). Rotate the

shaft " G " by hand slightly toward the left or right, as required.

Tighten screw " H " and check whether all parts are correctly

adjusted.

Loading...

Loading...