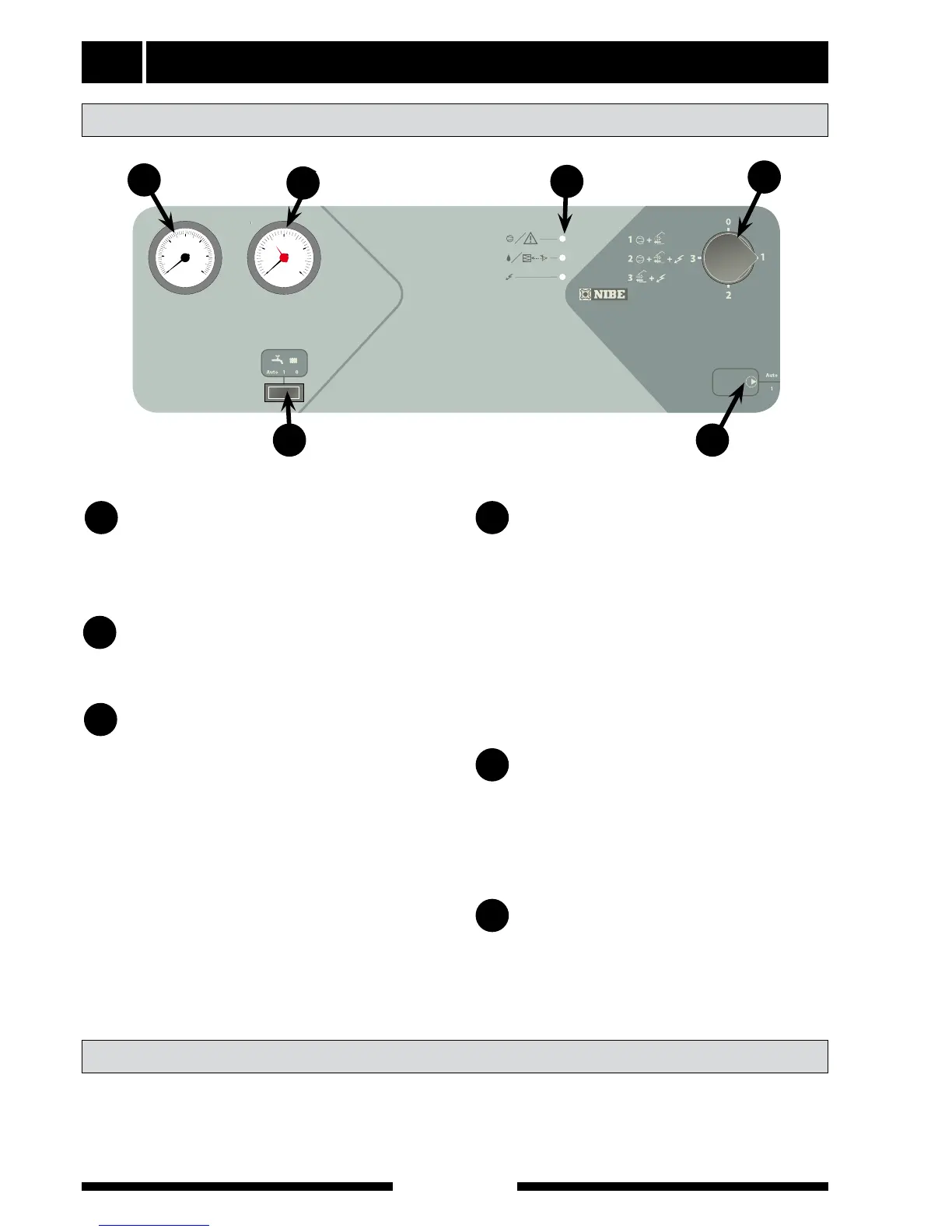

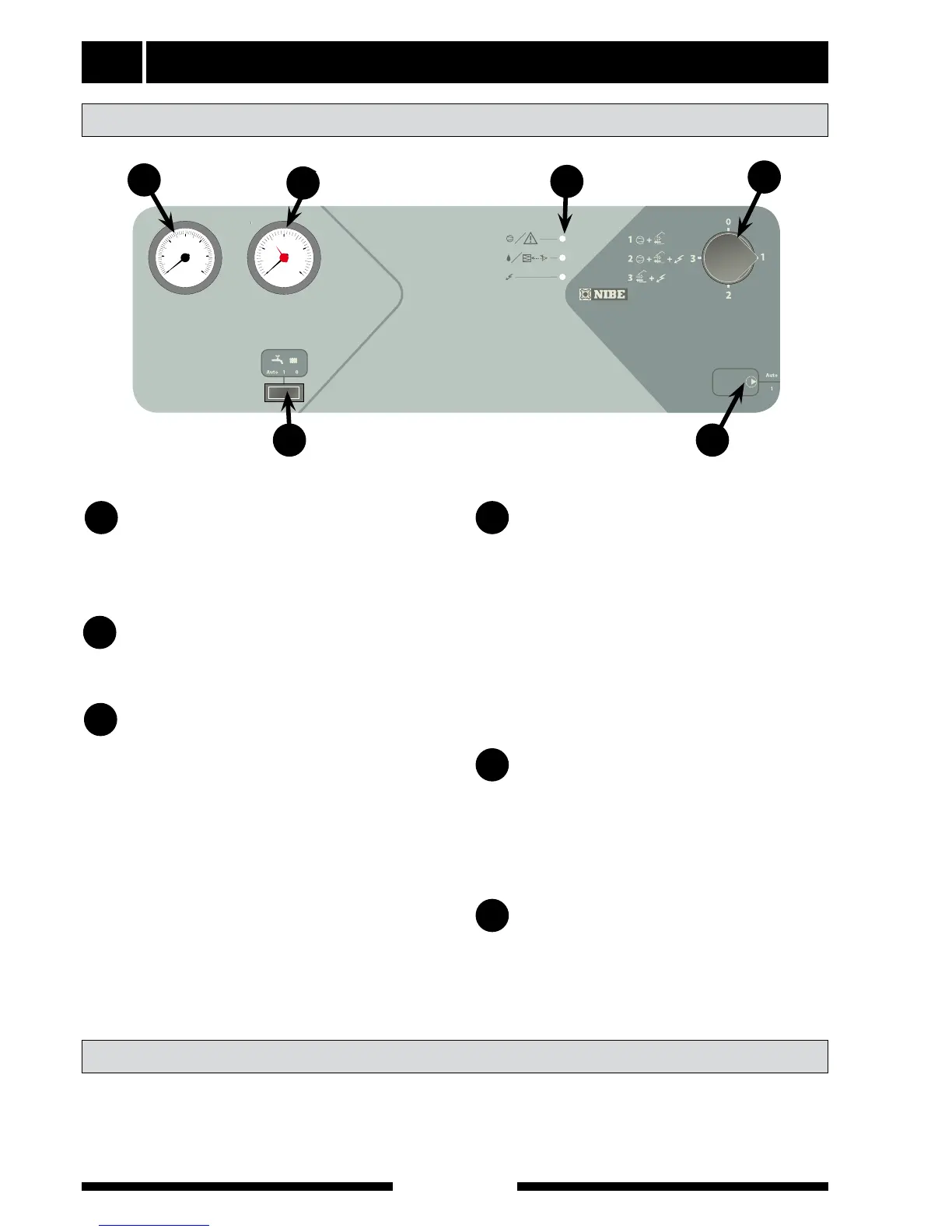

Front panel

FIGHTER 200P

For Home Owners

4

Thermometer

Here the boiler temperature is indicated . The

value depends on the cut-out temperature of

the immersion heater, the set value for the

compressor cut-out temperature and the hot

water taps.

A

C

Indicators lamps

Top lamp

Lit Compressor is running.

Flashing Alarming for tripped pressostates

or indicating standby mode (Com-

pressor blocked).

Not lit Compressor is not running.

Midmost lamp

Lit Defrosting is operational.

Flashing Air filter to be cleaned.

Not lit -

Lower lamp

Lit Immersion heater is in operation.

Flashing -

Not lit Immersion heater is not in opera-

tion.

Front panel functions

D

Switch

with 4 positions 0 - 1 - 2 - 3:

0 Heat pump off.

1 Fan is operational. Compressor and circula-

tion pump operational on demand.

2 Fan is operational. Compressor, immersion

heater and circulation pump operational on

demand.

3 Standby mode. Fan is operational. Compres-

sor is not operational. Immersion heater and

circulation pump operational on demand.

Pressure gauge

Here the pressure of the radiator circuit is

indicated . The scale marks go from 0 - 4 bars.

Normal pressure is 0,5 - 1,5 bar.

B

E

Hot water prioritising (hidden)

with 3 positions Auto - On - Off:

Auto Hot water prioritising operational

On Hot water prioritising operational

Off Hot water prioritising not operational

F

Circulation pump (hidden)

with 2 positions Auto - On:

Auto The On and Off of the circulation pump

is controlled by the control system.

On Circulation pump permanently running

Switch

Pressure gauge

Thermometer Indicator lamps

Hot water priority (hidden)

Circulation pump (hidden)

A

B

C

D

E F

The heat emission is controlled by means of a room

thermostat. On achieving the set temperature, the

circulation pump inside FIGHTER 200P will stop.

In order to set different intervals with a temperature

change we recommend the enclosed clock thermostat.

For time and temperature settings see section "Com-

missioning and adjusting" – "Operating instructions for

enclosed clock thermostat".

Automatic heating control system

Loading...

Loading...