2 – English

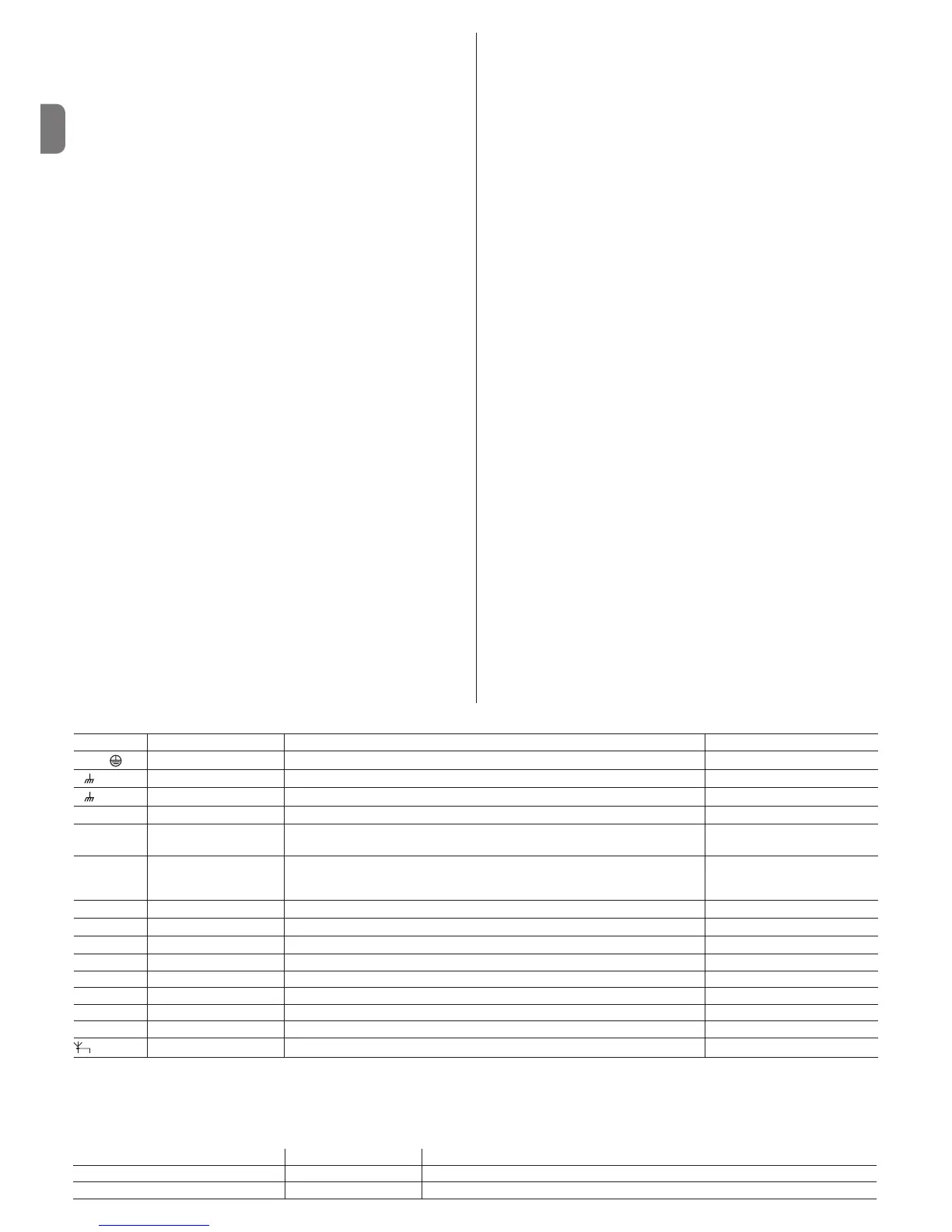

Function Input type Description

PARTIAL OPEN TYPE 1 NO Fully opens the upper leaf

PARTIAL OPEN TYPE 2 NO Opens the two leaf half way

To check the parts of the control unit see g. 2.

Key to g. 2:

A 24 V AC power supply socket

B Back-up PS124 battery / Solemyo solar energy power supply

system socket (for further details see chapter 6.3)

C Services fuse (2A, type F)

D “SM” connection for radio receiver

E MotorterminalM1(partrstclosed)

F MotorterminalM2(partrstopened)

G Flashing lights output terminal

H OGI or electric locking output terminal

I 24 V DC terminals for services and phototest

L9..L13 Input LEDs

OK "LED OK" LED status

L1..L8 Programming LEDs

LR Radio programming LED

M Terminals for inputs

N Terminal for radio aerial

O Motor selector switch

Q Connector for IBT4N

R Networkfuse(see:technicalspecicationsofproduct)

S Networksupply(L-Line;N-Neutral)(see:technicalspecications

of product)

T Connection to earth

U Pressacavo

P1..P3 Buttons to programme control unit

P4 Button to programme radio

2.1 - Preliminary checks for installation

Before proceeding with installation, check the condition of the product compo-

nents, suitability of the selected model and conditions of the intended installa-

tion environment:

• Ensure that all conditions of use remain within the limits of product application

andwithinthe“Producttechnicalspecications”.

• Ensure that the selected installation environment is compatible with the over-

all dimensions of the product (g. 3).

• Ensure that the selected surfaces for product installation are solid and guar-

anteeastablexture.

•Makesurethatthexingzoneisnotsubjecttoooding.Ifnecessary,mount

the product raised from the ground.

• Ensure that the space around the product enables easy and safe completion

of manual manoeuvres.

• Make sure that the automation is provided with mechanical stops on both

closing and opening.

2.2 - Product application limits

The product may be used exclusively withWG2024, WG3524, WG4024,

WG5024,TOO3024,TOO4524,XME2024gearmotors.

2.3 - Installation

To install the control unit, proceed as shown in g. 4. Also observe the follow-

ing warnings:

• The control unit is supplied in an enclosure that if correctly installed assures

anIP54protectionrating.Thecontrolunitisthereforesuitableforinstallation

outdoors.

•Fixthecontrolunittoaat,vertical,non-removablesurfacethatisadequately

protected from potential impacts. Important! – The bottom of the control unit

must be at least 40 cm from the ground.

• Insert the dedicated cable clamps or pipe glands into the lower part of the

enclosure (g. 4). Important! – If the cable protection tubes end in a pit, it is

likely that condensation will form inside the control unit, which will damage the

electronic board. In this case, protect the control unit adequately so as to pre-

vent the formation of condensation.

• The cable clamps can be inserted on the long side of the enclosure only if the

control unit is installed in a protected indoor environment.

To install the other devices present in the automation, refer to the relevant

instruction manuals.

2.4 - Electrical connections

IMPORTANT!

– All electrical connections must be made with the unit disconnected

from the mains power supply and with the buffer battery disconnected,

if present in the automation.

– Connections must be made exclusively by qualied personnel.

– Make sure that all the electric cables used are of a suitable type.

01. Loosen the screws of the cover.

02. Prepare the electrical cable routing holes.

03. Connect the cables, referring to the electrical diagram shown in g. 5. To

connect the electrical power supply cable, vedere g. 2 e g. 6 nei punti

R, S, T, U. To secure the cable, use the cable clip U.

Note – To facilitate cable connections, the terminals can be removed from

their seats.

• With the exception of the photocell inputs when the PHOTOTEST function

is activated, if the inputs of the NC (Normally Closed) contacts are not in use

they should be jumped with the “COMMON” terminal. Refer to paragraph

2.4.3 for further information.

• If there is more than one NC contact on the same input, they must be con-

nected in SERIES.

• If the inputs of the NO (Normally Open) contacts are not used they should be

left free.

• If there is more than one NO contact on the same input, they must be con-

nected in PARALLEL.

• The contacts must be electromechanical and potential-free. Stage connec-

tions,suchasthosedenedas“PNP”,“NPN”,“OpenCollector”,etc.arenot

allowed.

• in the case of overlapping doors, you can select which motor must start

openingrstbyconnectingittoterminalM2.

Key to gs. 2 - 5a - 5b - 5c:

Terminals Function Description Type of cable

L - N -

Power supply line Mains power supply 3x1,5mm

2

M M

Motor 1 M1 motor connection (Note 1) 3x1,5mm

2

M M

Motor 2 M2 motor connection 3x1,5mm

2

1÷2 Flashing light

Connectionofashinglight24V

𝌂

max25W

2 x 1 mm

2

3÷4 Open Gate indicator /

Elect.Lock

Connection for Open Gate Indicator 24 V

𝌂

max5WorElectriclock12V

𝌂

max

25VA(“Seechapter5-Programing”)

OGI:2x0,5mm

2

Electric lock: 2 x 1 mm

2

5

Common 24 V

𝌂

(with

Everything in stand by /

phototest)

Power Supply +24 V

𝌂

for TX photocells with phototest (max. 100 mA); “COM-

MON” for all inputs, safety, with “Everything in stand by” function activated (Note 2)

1x0,5mm

2

6

0 V

𝌂

Power supply 0V

𝌂

for services

1x0,5mm

2

7

24 V

𝌂

Power input for services, without “Everything in stand by” (24 V

𝌂

max 200 mA)

1x0,5mm

2

8

Common 24 V

𝌂

Common for all inputs (+24 V

𝌂

) without “Everything in stand by”

1x0,5mm

2

9 ALT Input with ALT function (emergency, safety shutdown) (Note 3) 1x0,5mm

2

10 PHOTO NC Input for safety devices (photocells, sensitive edges) 1x0,5mm

2

11 PHOTO 1 NC Input for safety devices (photocells, sensitive edges) 1x0,5mm

2

12 STEP BY STEP Input for cyclical functioning (OPEN-STOP-CLOSE-STOP) 1x0,5mm

2

13 AUX Auxiliary input (Note 4) 1x0,5mm

2

Aerial Connection for the radio receiver aerial screenedcabletypeRG58

Note 1 – This is not used for single leaf gates (the control unit automatically recognises if only one motor has been installed).

Note 2 – The “Everything in stand by” function serves to reduce consumptions. For further details on the electrical connections refer to paragraph 2.4.1 ““Every-

thing in stand by/Phototest connection” and for programming refer to chapter 5.2 “Programmable functions”.

Note 3 – The STOP input can be used for “NC” or constant resistance 8.2 kΩ contacts during auto-recognition (please refer to the “Programming” chapter).

Note 4 – The AUX factory auxiliary input is programmed with the “Partial open type 1” function but can be programmed with any of the following functions:

Loading...

Loading...