19

TROUBLESHOOTING COMMON PROBLEMS

MAINTENANCE

WARNING:

Inspection, testing and repair of electrical equipment should be performed only by

qualied service personnel. Certain procedures in this section require electrical tests

or measurements while power is applied to the machine.

EXERCISE EXTREME CAUTION AT ALL TIMES.

If test points are not easily accessible, disconnect power, attach test equipment and

reapply power to test. When replacing electrical parts, disconnect power at source

circuit breaker.

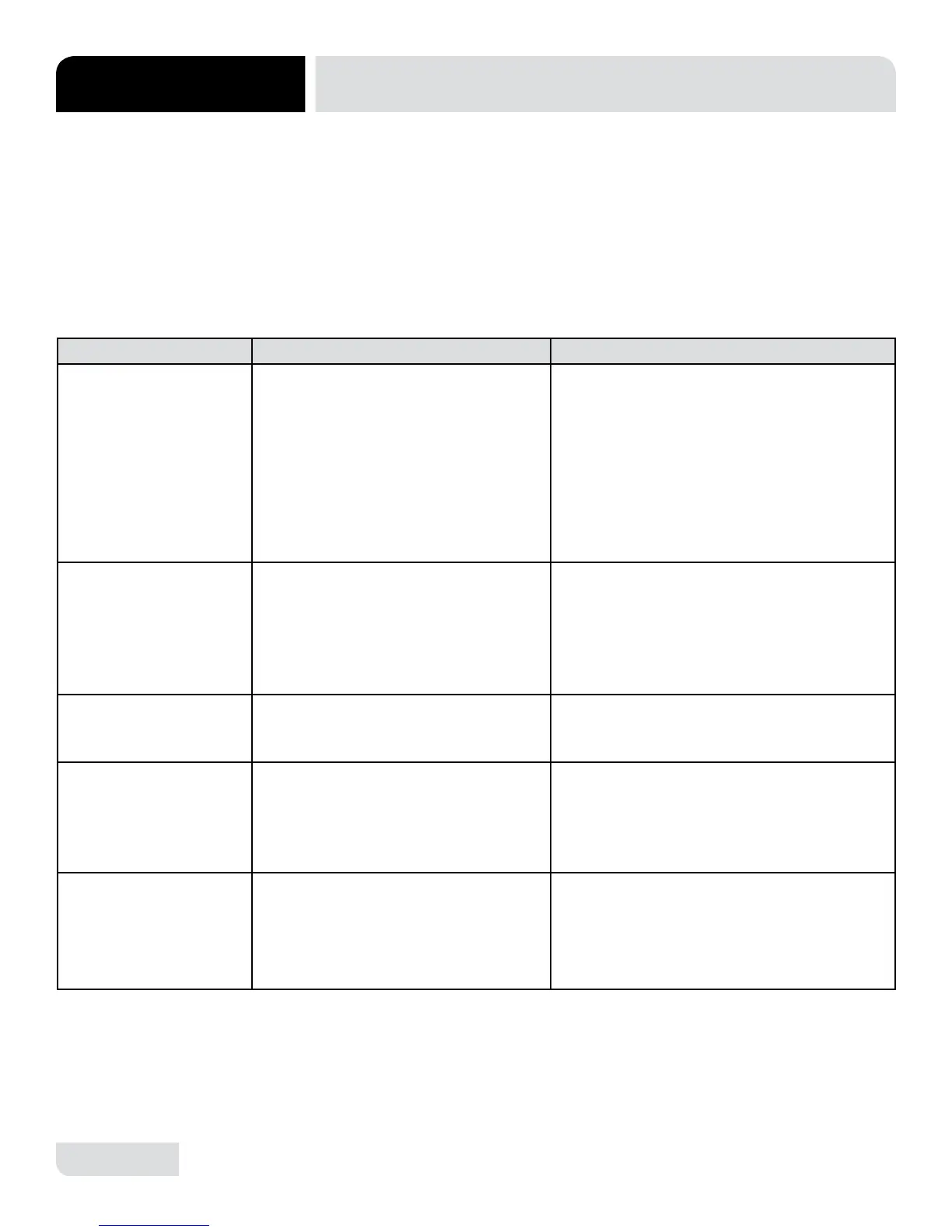

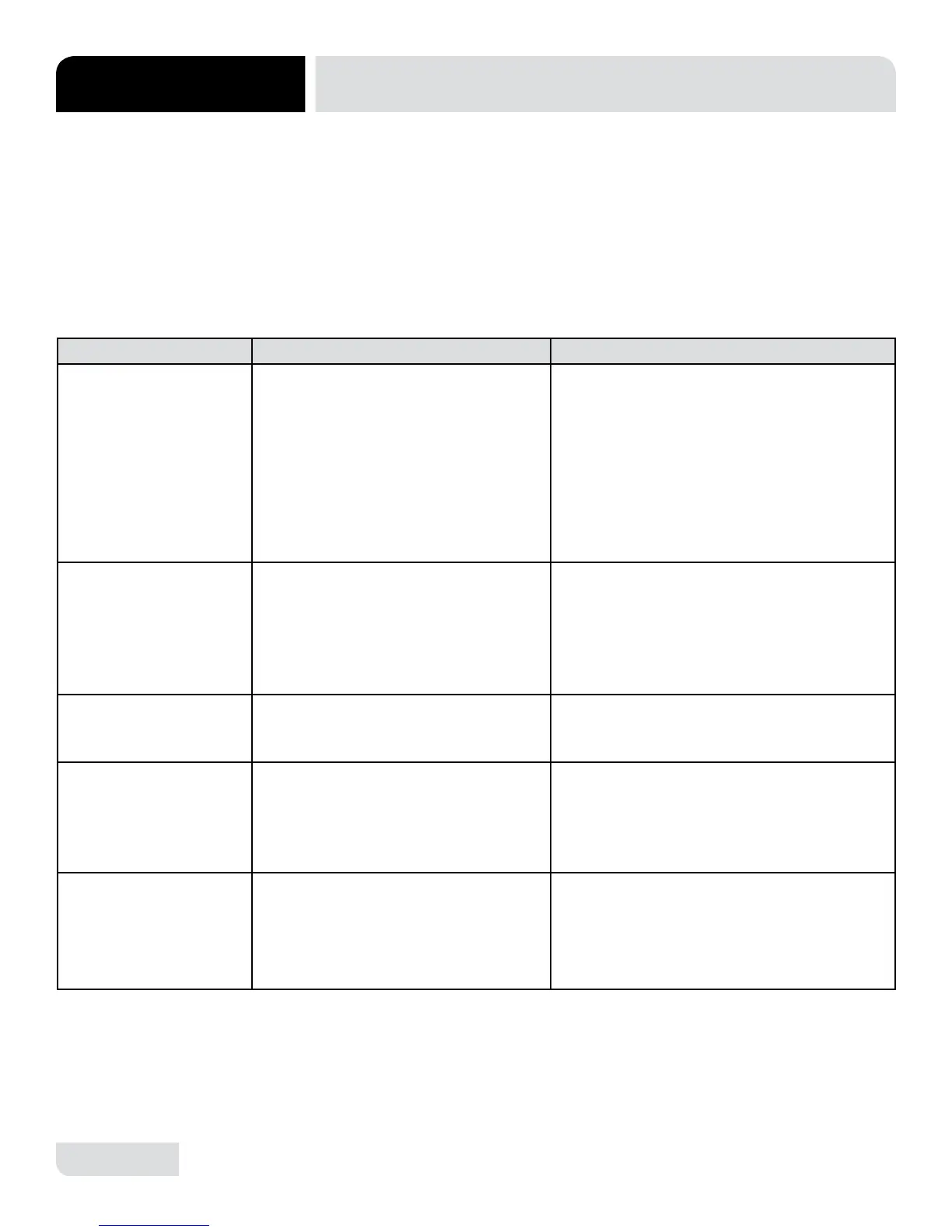

PROBLEM POSSIBLE CAUSE REMEDY

Water overow from

bottom of door.

1. Clogged drain.

2. Machine not level.

3. Excessive inlet pressure.

4. Detergent foaming

1. Remove obstruction.

2. Level machine, or increase height to the front.

3. Install pressure reducing valve, or adjust if

one is present. Ensure ow is 20 ±5 PSI.

4. Reduce detergent quantity.

Wash motor doesn’t oper-

ate on manual wash.

1.Loose or broken wires.

2.Defective manual wash switch

3.Defective motor starting relay.

1. Reconnect or replace wires in motor.

2. Replace.

3. Replace.

Motor operates on manual

wash but not on automat-

ic.

1. Defective circuit in manual wash

switch.

1. Replace switch.

No water comes through

the rinse arms when the

“ON/FILL” switch is de-

pressed.

1. Water not turned on.

2. Defective solenoid valve.

1. Turn water on.

2.Replace solenoid valve.

Little or no water coming

through the rinse assem-

blies.

1. Limed up rinse heads or piping.

2. Low water pressure.

1. Delime rinse heads.

2. Increase pipe size to machine. Adjust pres-

sure regulator.

Loading...

Loading...