- 12 -

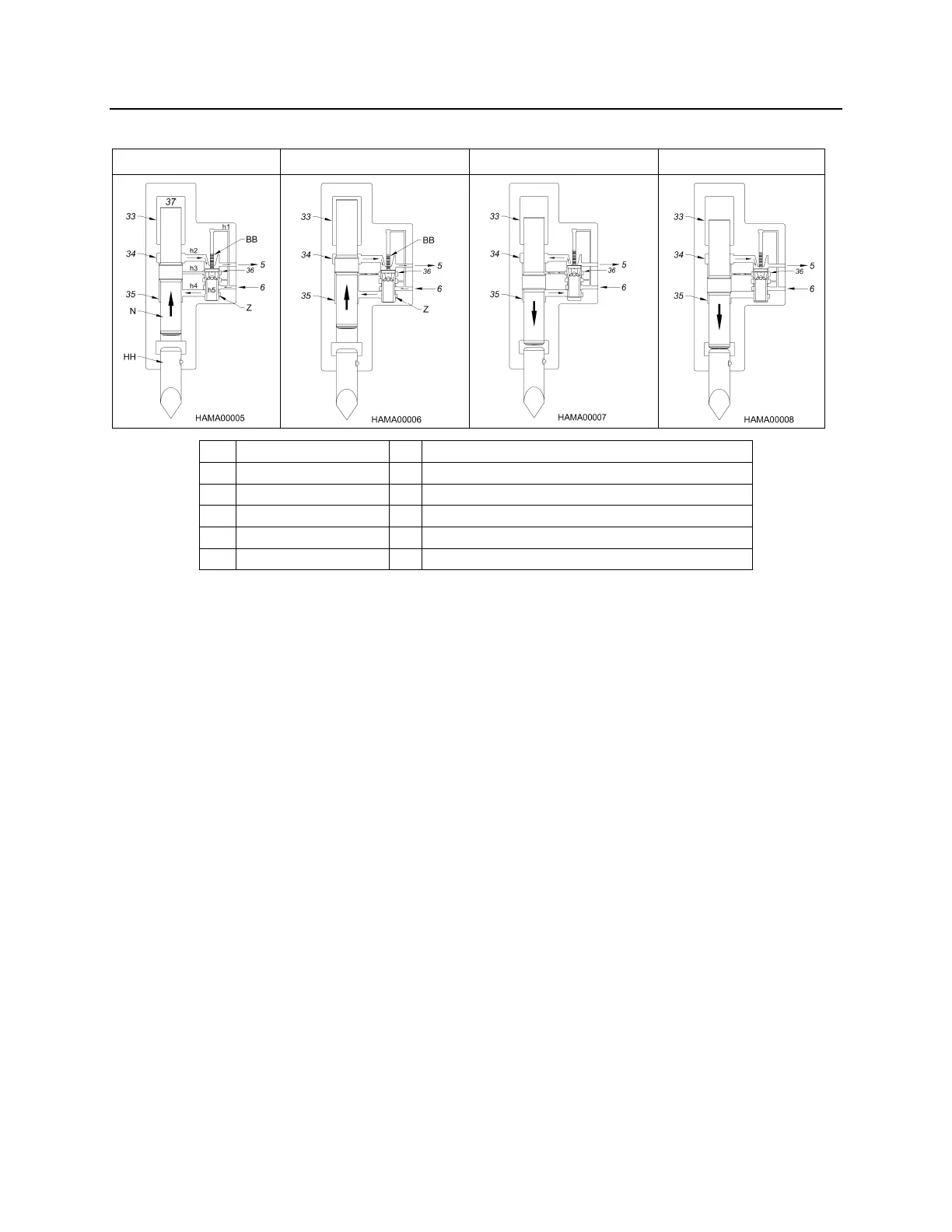

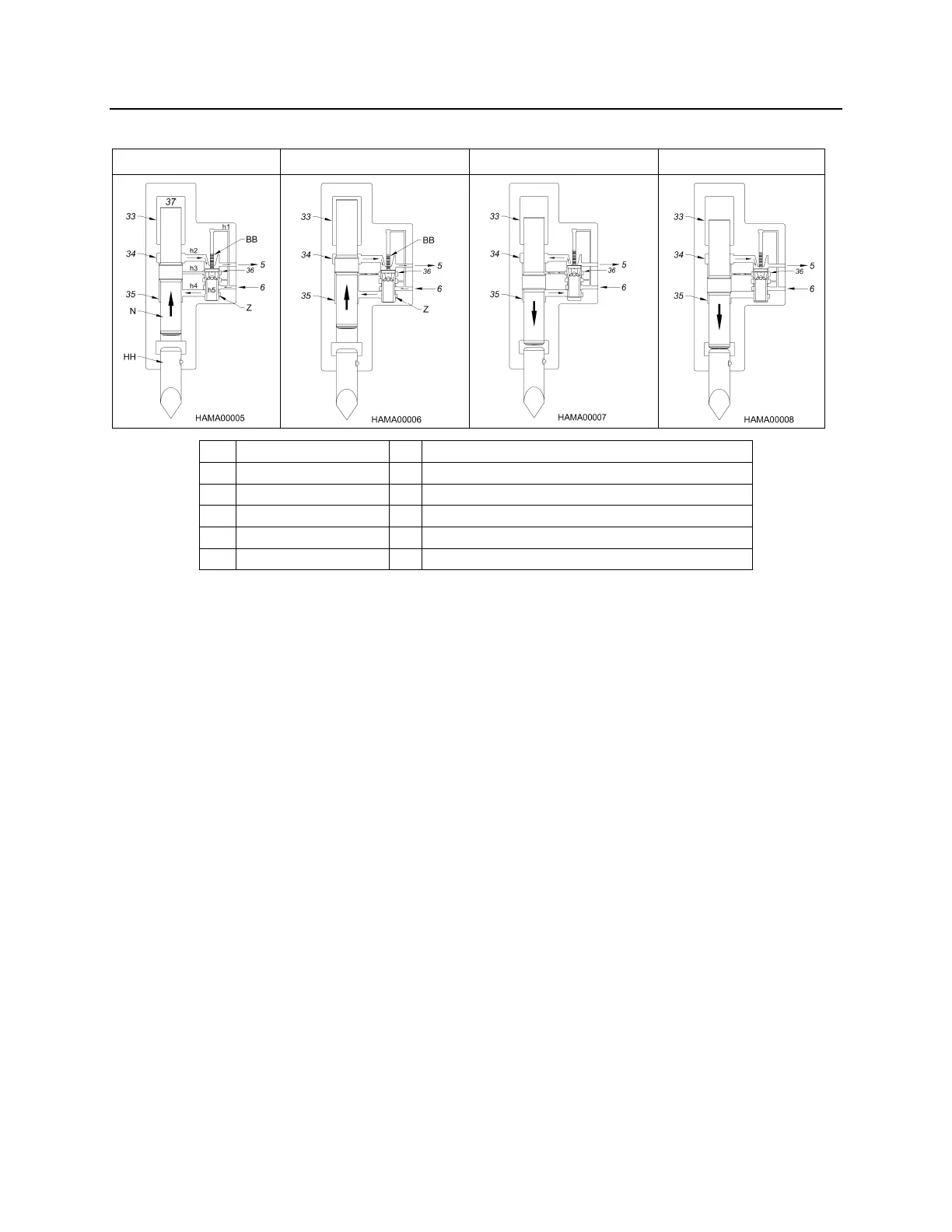

PRINCIPLE OF OPERATION

OPEN VALVE

(1) UPSTROKE (2) VALVE SHIFT (3) POWER STROKE (4) IMPACT

N

PISTON 33 NITROGEN GAS CHAMBER ABOVE PISTON

Z

MAIN VALVE SPOOL 34 UPPER CHAMBER OF PISTON

BB

PLUNGER 35 LOWER CHAMBER OF PISTON

HH

TOOL 36 CHAMBER OF VALVE SPOOL

5 OUT PORT 37 NITROGEN GAS

6 IN PORT

(1) UPSTROKE OF PISTON

Hydraulic oil supplied by the carrier machine hydraulic pump enters the NPK HAMMER

"IN" port (6) and is directed through port (h1) to the top of the valve plunger, forcing the

main valve spool (Z) to the down position. Oil flows through the main valve spool (Z) to

the lower chamber of the piston (35). The oil pressure acts on the piston (N), raising the

piston up, compressing the nitrogen gas (37). Oil in the upper chamber of the piston (34)

is forced out the return line through port (h2).

(2) VALVE SHIFT

As the piston (N) rises, lower chamber (35) is opened to passage (h3) and oil flows into

the chamber (36) of the main valve spool (Z). Since the area acting on the main valve

spool (Z) in chamber (36) is greater than the area of the plunger (BB), the main valve

spool (Z) shifts up.

(3) POWER STROKE

With the main valve spool (Z) in the up position, chamber (35) is closed off from the "IN"

port (6) and opened to chamber (34) and the return line via passages (h4), (h5), and (h2).

The piston (N) is driven downwards by the compressed nitrogen gas (37) as the oil in

lower chamber (35) re-circulates to upper chamber (34). When the piston (N) opens

passage (h3) to upper chamber (34), the oil in main valve spool chamber (36) is switched

to low pressure and the main valve spool (Z) shifts down.

(4) IMPACT

The piston (N) impacts the tool (HH) and the main valve spool (Z) shifts to the down

position. High pressure oil is directed to the lower chamber of the piston (35) for the start

of another cycle.

AUTOMATIC ENERGY RECYCLING: Extremely hard material will impart greater rebound

energy to the piston (N) after it strikes the tool (HH). This will assist the incoming oil in raising

the piston (N) against the gas pressure in chamber (33). This reduces upstroke time and

therefore increases hammer frequency (beats per minute). The impact force of the hammer

remains the same on each impact.

Loading...

Loading...