- 64 -

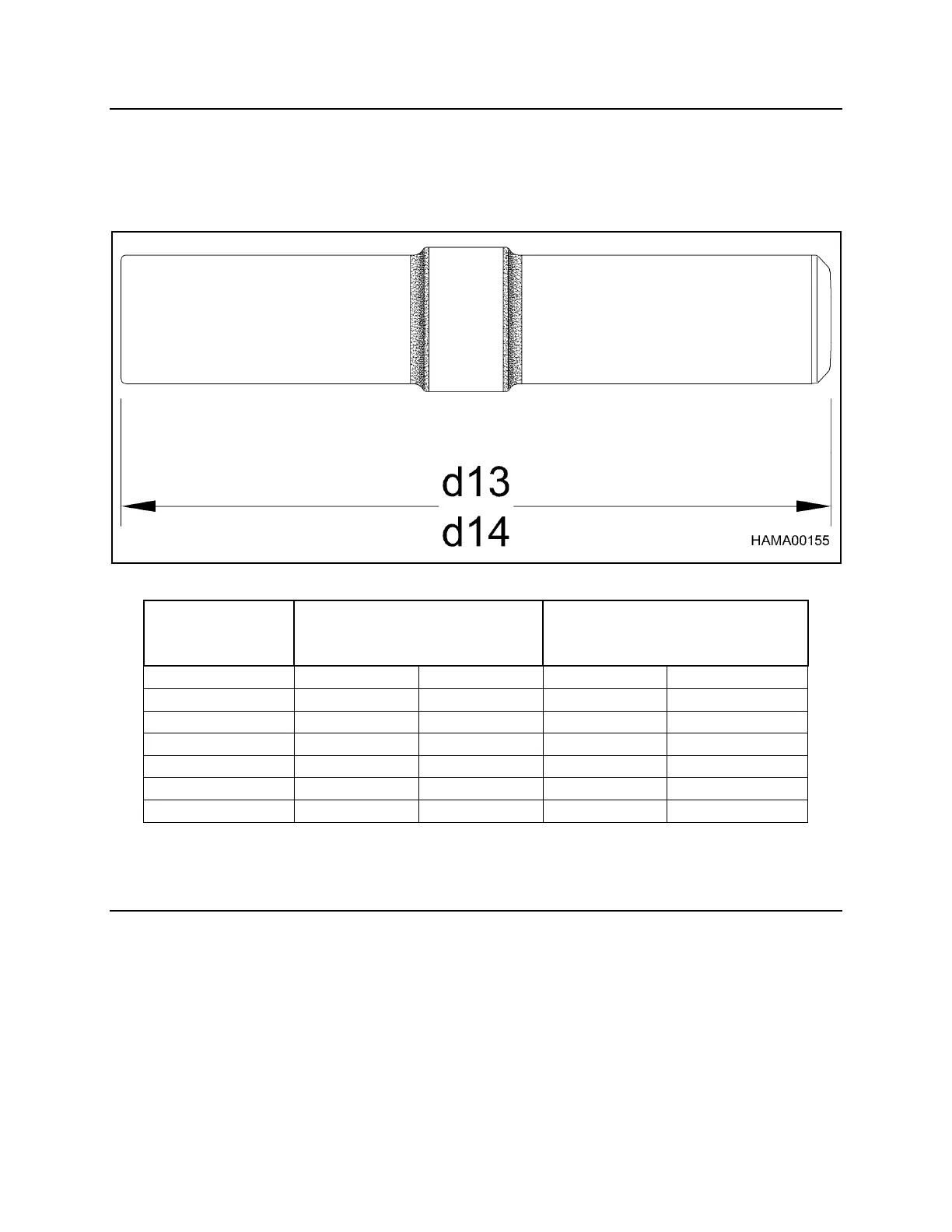

REPAIR THE STRIKING END OF PISTON

The NPK piston is designed for maximum fatigue resistance to failure of the striking

face. The striking face can become indented and mushroomed when the hammer has

been used for a long time or operated with worn-out tool bushings. To repair the piston,

dress the tool striking end with a grinder.

MODEL

NEW d13 MINIMUM d14

inch mm inch mm

GH06 13 329 12.70 323

GH07 13.10 332 12.80 326

GH1 15.60 396 15.30 388

GH2/GHS2 16 406 15.70 398

GH3 17.90 454 17.50 444

GH4 21.40 544 21.00 534

GH6 23.50 598 23.10 588

MAIN BODY SLEEVES

REPAIR OF SLEEVE INSIDE DIAMETER

Scoring or galling may occur when the hammer has been used for a long period of time;

or operated with worn-out tool bushings, loose tie rods, overheated hydraulic system, or

contaminated hydraulic oil. If the sleeve has slight scratches or scoring, then repair by

polishing. Call NPK for detailed information.

If the sleeve is damaged from scoring or galling in the axial direction, the oil grooves

may be filled with metallic particles. The oil grooves must be cleaned or they will cause

additional scoring.

Loading...

Loading...