- 28 -

EXCESS OIL IN THE GAS HEAD INSPECTION

PROCEDURE

As the low pressure oil piston seal in the “A” Sleeve starts to wear out, the piston

may pull oil into the gas head. The gas volume is then decreased and the hydraulic

oil pressure required to move the piston to its full upstroke position increases.

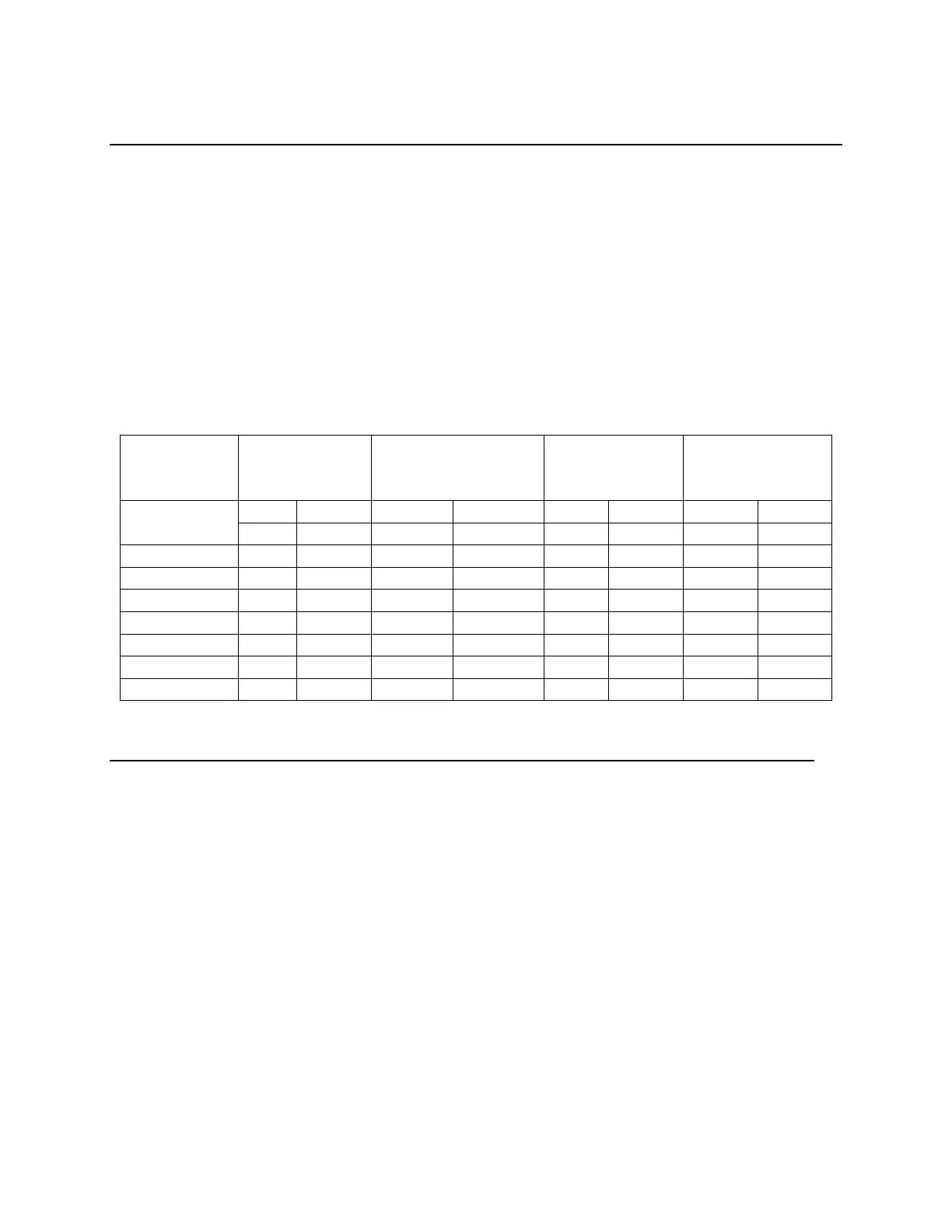

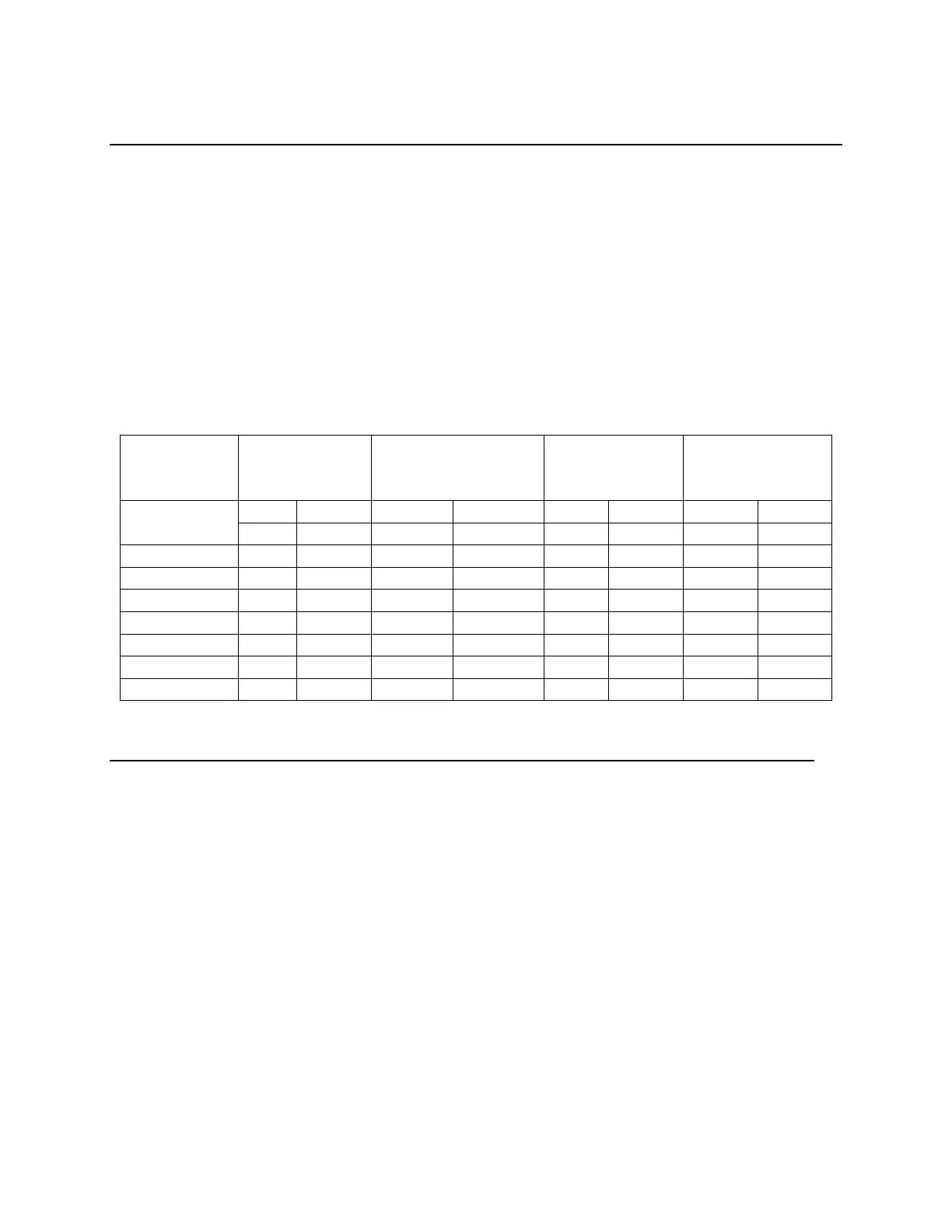

With the hammer suspended, check and adjust the nitrogen gas pressure to the

ambient or to the hot specification shown in the chart below.

Load the hammer by pressing it against a solid object until the tool stops up inside.

The gauge reading should not be much above the loaded gas pressure shown on

the chart below. If the loaded gas pressure is high, there is excess oil in the gas

head and the hammer must be resealed.

MODEL

PRE-

CHARGE

AT LOAD

PRE-CHARGE

AT LOAD

Cold Cold Cold Cold Hot Hot Hot Hot

psi bar psi bar psi bar psi bar

GH06 350 24 385 26.5 405 28 450 31

GH07 350 24 385 26.5 405 28 450 31

GH1 350 24 400 27.5 405 28 465 32

GH2/GHS2 350 24 400 27.5 405 28 465 32

GH3 350 24 400 27.5 405 28 465 32

GH4 375 26 425 29.5 435 30 495 34

GH6 390 27 440 30.5 450 31 505 35

NOTES:

1. Cold gas charge is the initial set with the hammer at ambient temperature.

2. Hot gas charge is checked after 1 to 2 hours of running and with a system oil

temperature of 140° to 180°F (60° to 80°C). This is the preferred check.

Loading...

Loading...