- 65 -

REPLACING THE SEALS

If the gas pressure drops more than 25 psi (2 bar) a day or a large oil leak is found,

replace the seals.

Check the seals, seal grooves, and piston active seal areas for damage.

1. Small nicks may be removed with a suitable hone.

2. When large or deep nicks are found, replace the part.

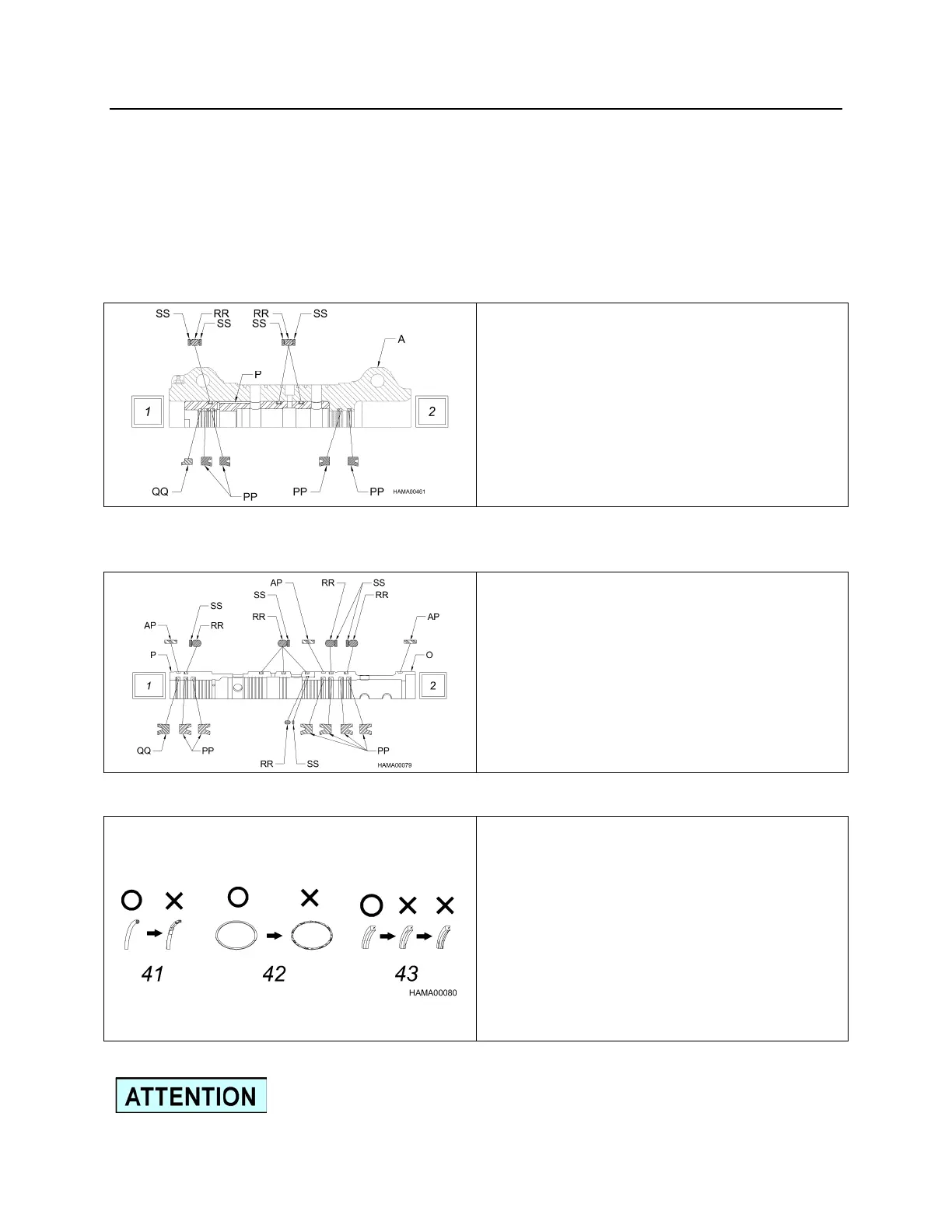

GH06 – GH3

A. BODY

P. “B” SLEEVE

PP. U-CUP SEAL

QQ. DIRT SEAL

RR. O-RING

SS. BACKUP RING

1. TOOL END

2. GAS END

NOTE: GHS2 has extra machining for the anti-blank firing feature.

GH4 – GH6

O. “A” SLEEVE

P. “B” SLEEVE

AP. WEAR BAND

PP. U-CUP SEAL

QQ. DIRT SEAL

RR. O-RING

SS. BACKUP RING

1. TOOL END

2. GAS END

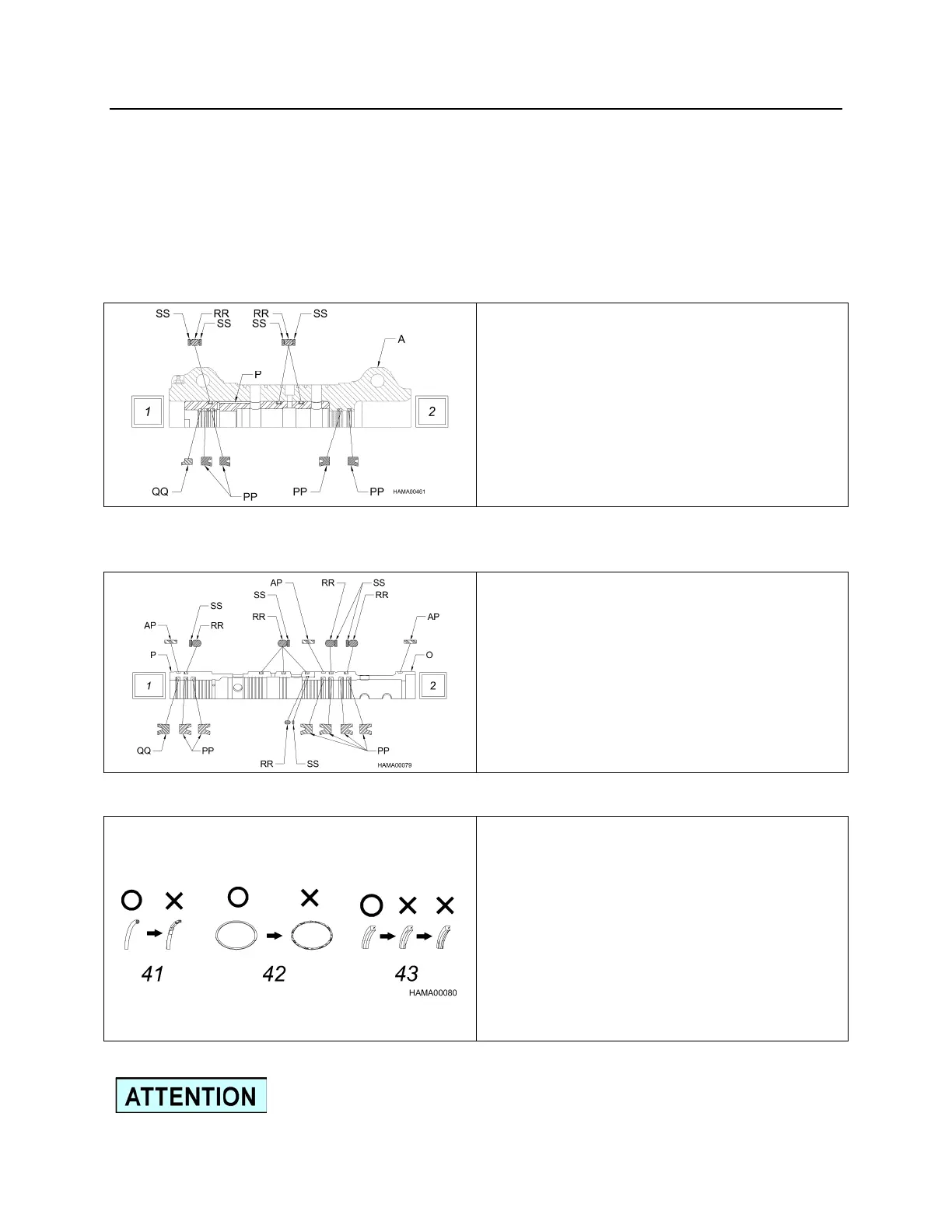

(DEFECTIVE SEALS)

ALL DEFECTIVE SEALS SHOULD BE

REPLACED WITH NEW ONES.

41. O-RINGS DEFORMED, WORN,

WARPED, DAMAGED OR

DETERIORATED

42. BACKUP RINGS WORN OR

DEFORMED

43. U-CUP SEALS WORN OR

DETERIORATED

Some minor leakage may be found for a while after new oil

seals are installed, the oil leak will stop when the seal seats

itself in use.

Loading...

Loading...