- 70 -

REASSEMBLY OF THE HAMMER

ALTERNATE METHOD OF INSTALLING THE PISTON AND

SLEEVES INTO THE MAIN BODY

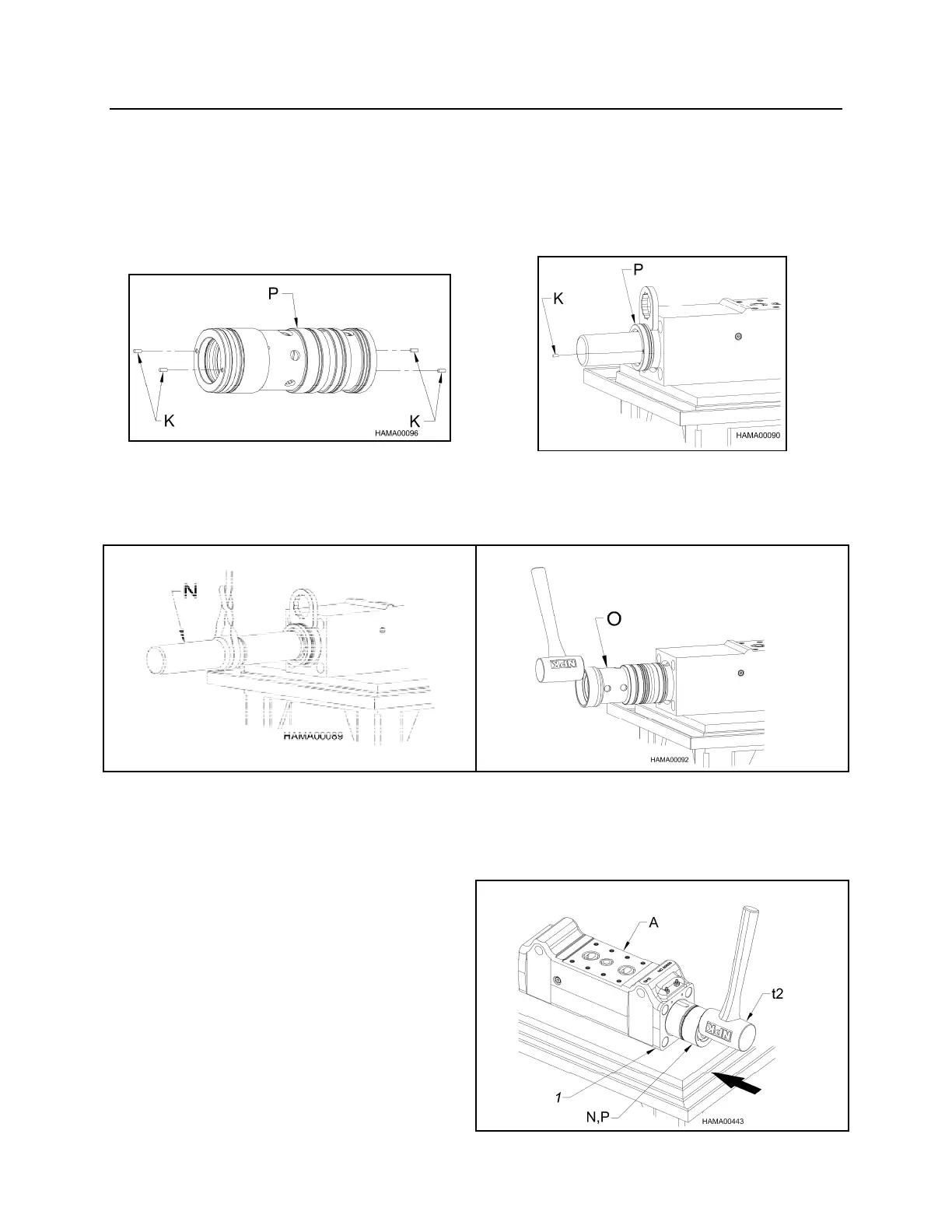

2. Install two dowel pins (K) into each end of “B” sleeve (P). Apply a sufficient

amount of grease to prevent the pins from falling out.

3. Using a lock plate as a stop to keep “B”

sleeve (P) from going any further at this

point.

4. Install the piston (N). 5. Install “A” sleeve (O).

Carefully insert the piston (N) into “B”

sleeve from the gas end of the main body.

Apply lubricating oil or NPK assembly lube

to inside and outside diameters of “A”

sleeve (O). Align dowel pin holes and

install “A” sleeve (O) onto piston (N), flush

with “B” sleeve (P).

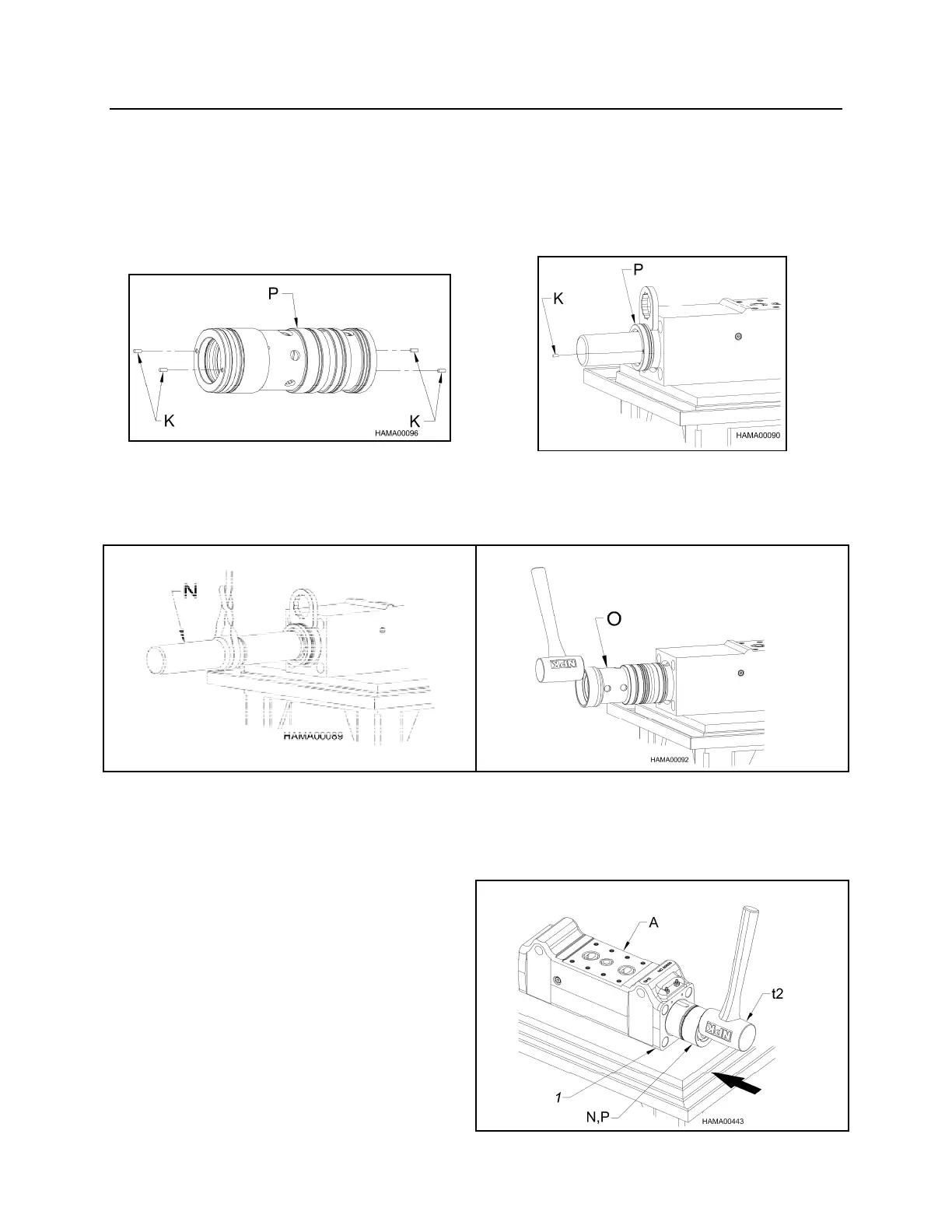

a. MODELS GH06 - GH3

Tap the “B” sleeve (P) and the

piston (N) into the hammer body (A)

from the tool end (1) gently tapping

using a dead blow hammer (t2) as

shown.

Loading...

Loading...