32

Installation Section 3-1

Tighten the screws on the terminal block to a torque of 0.8 N⋅m.

Recommended Terminals

Note Conformance to Shipbuilding Standard

• Use gaskets or other materials to completely shield all openings and

other gaps in the control panel.

• Use copper tape or other electrically conductive tape to shield gaps

between the cutout and the PT before securing the PT in place.

• To suppress noise terminal voltage, perform installation under the follow-

ing conditions. It is recommended to use the following product for the DC

power supply.

Recommended Power Supply model: S82K-03024

Manufacturer: OMRON

3-1-4 Grounding

The NT31/NT31C has a functional ground terminal ( ).

Carry out wiring under the following conditions.

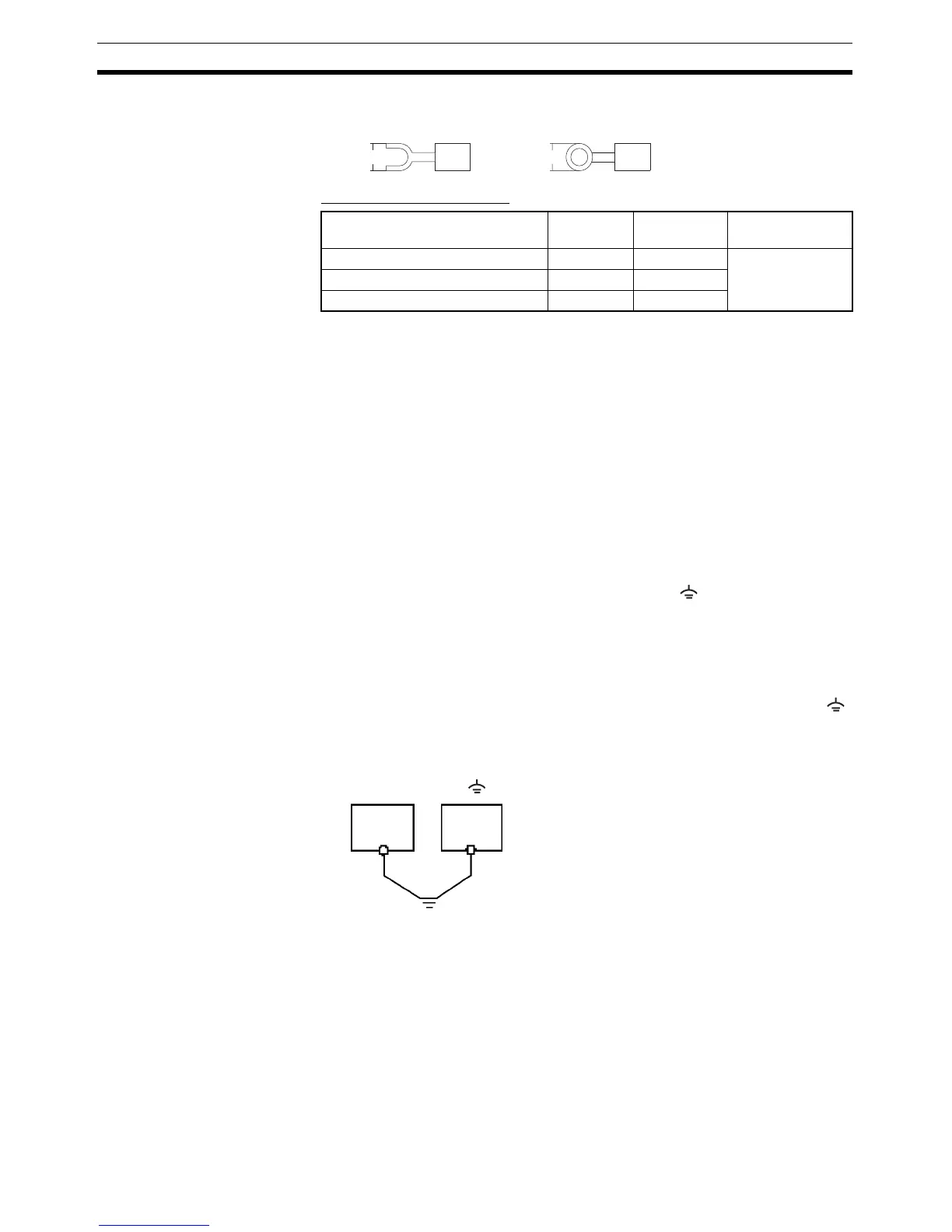

1,2,3... 1. In cases where there is a potential difference between the grounds of the

NT31/NT31C and the host, ground as shown in the following figure. If there

is some distance between the NT31/NT31C and host and grounding at a

single point is difficult, do not connect the functional ground terminal ( )

of the NT31/NT31C.

2. If the NT31/NT31C is installed in the same panel as equipment that gen-

erates noise, such as a motor or inverter, do not ground the functional

ground terminal ( ) of the NT31/NT31C.

Note Carry out grounding correctly in order to prevent operating errors due to

noise.

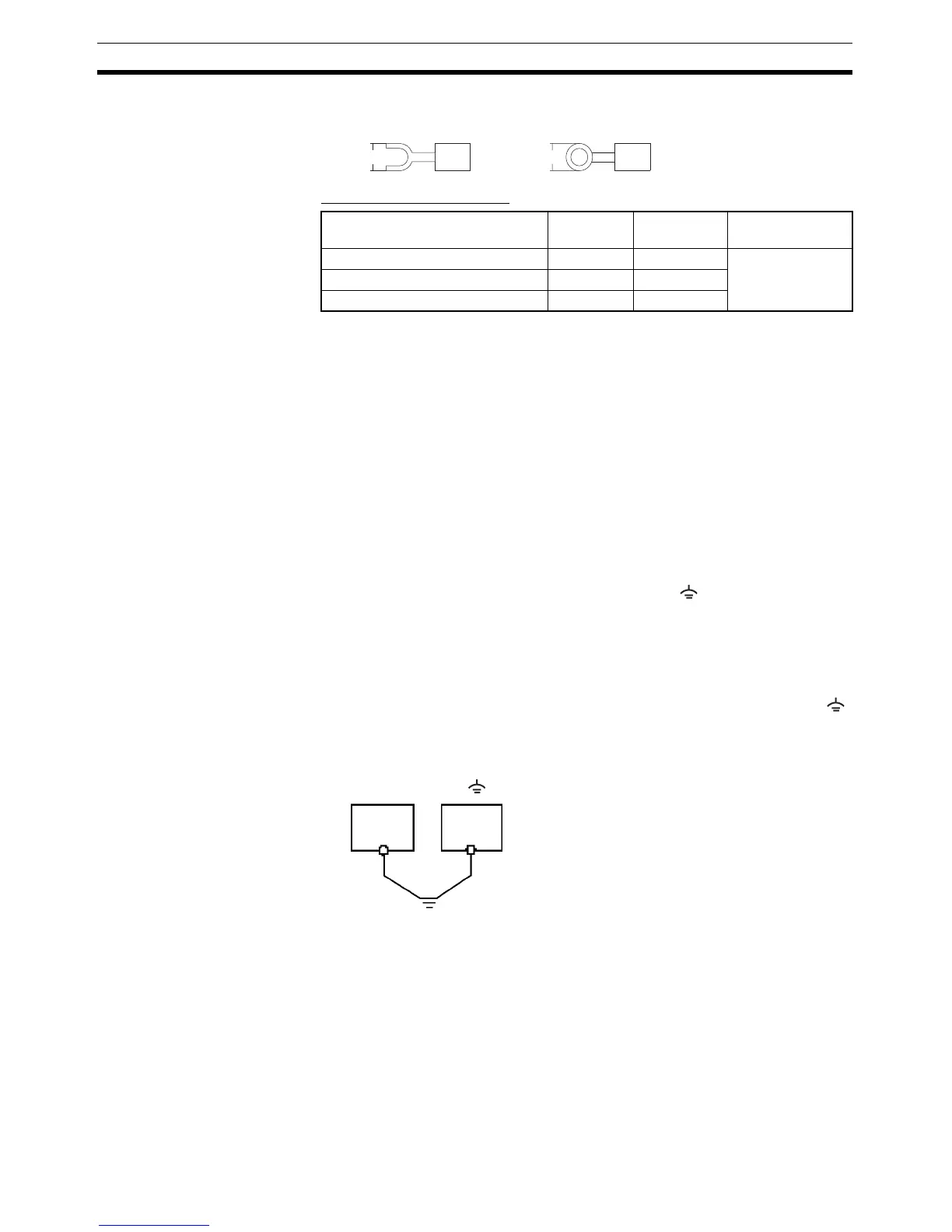

Maker Type

(fork type)

Type

(round type)

Applicable Wire

(stranded wire)

Japan Solderless Terminal MFG 2-YS3A 2-3.5

2.0 to 2.63 mm

2

Fuji Terminal 2-YAS3.5 V2-S3.5

Nichifu Terminal 2Y-3.5 2-3.5

Fork type Round type

7 mm max. 7 mm max.

Host

NT31/

NT31C

Grounding at

a single point

Loading...

Loading...