12 - 43

12 Troubleshooting

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

12-5 Troubleshooting

12

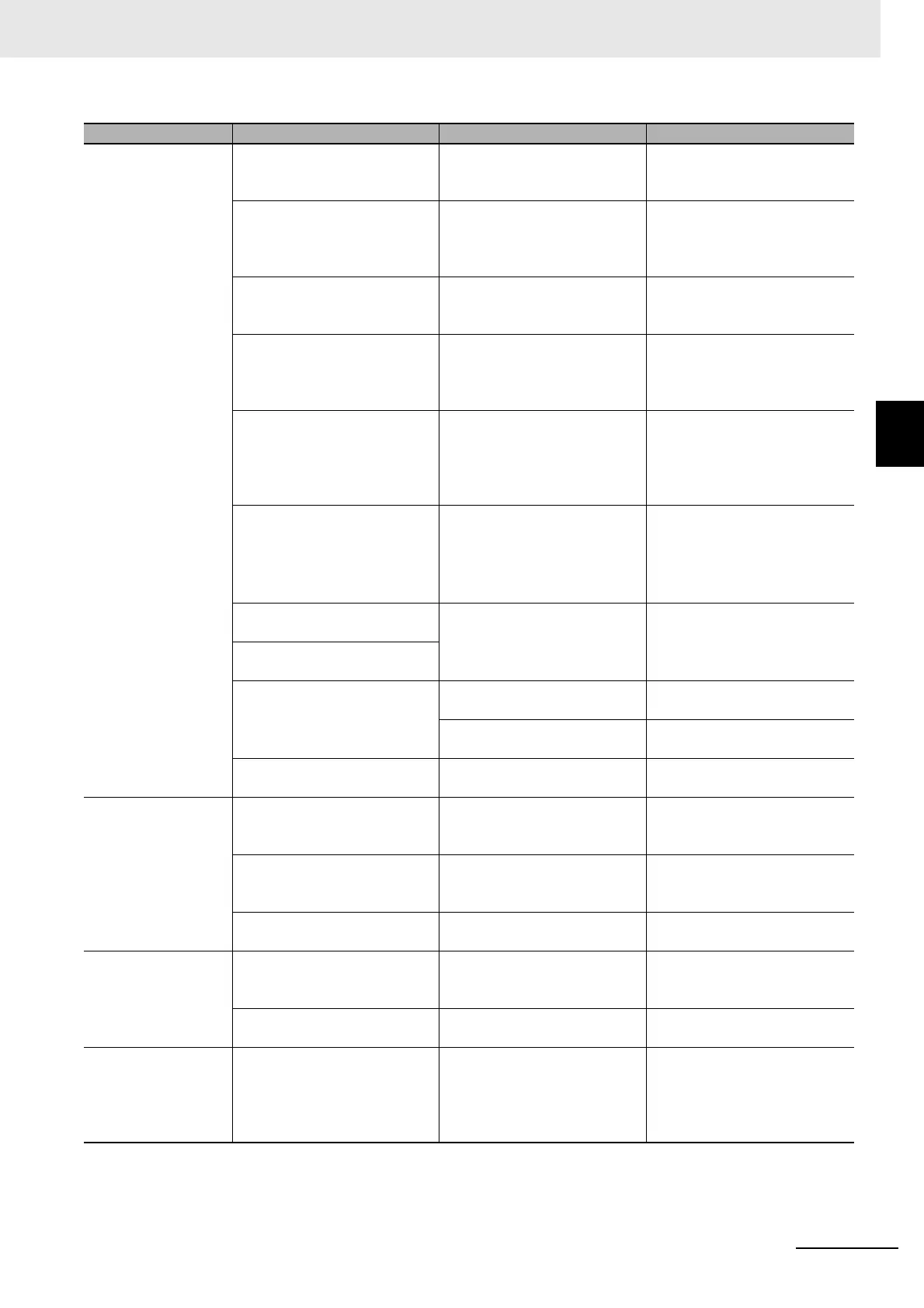

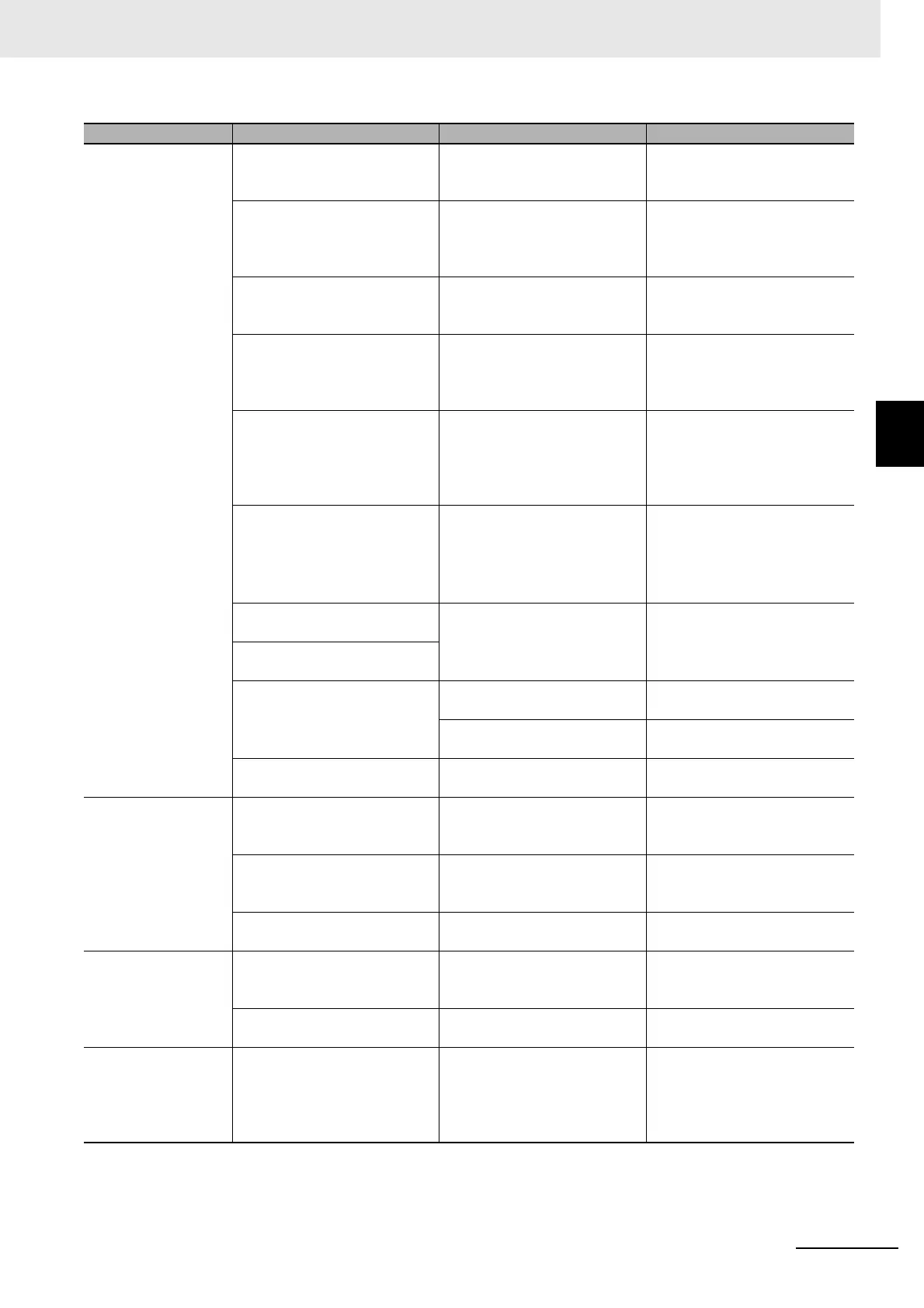

12-5-3 Troubleshooting Using the Operation State

The Servo locks but

the Servomotor does

not rotate.

The host controller does not

give a command.

For a position command, check

to see if the speed and position

are set to 0.

Enter position and speed data.

Start the Servomotor.

The Servo Drive received a

command but it is not

accepted.

Check to see if the Servo Drive

retains the object value for two

communications cycles or more

in Profile position mode (pp).

Set the Servo Drive so that it

retains the object value for two

communications cycles or

more.

It is hard to determine if the

Servomotor is rotating.

Check to see if the velocity

command given by the host

controller is too small.

Check the velocity command

from the host controller.

The holding brake is operating. Check the Brake Interlock Out-

put (BKIR) signal and the +24

VDC power supply.

Check to see if the holding

brake on a Servomotor with

brake is released when the

Servo is locked.

The torque limits set in the

Positive torque limit value

(60E0 hex) and the Negative

torque limit value (60E1 hex)

are too small.

Check to see if the torque limits

in objects 60E0 hex and 60E1

hex are set to a value close to

0.

Set the maximum torque that

you use for each of these

objects.

Positive Drive Prohibition Input

(POT) or Negative Drive Prohi-

bition Input (NOT) is OFF.

Check the ON/OFF state of the

POT and NOT signals from the

Sysmac Studio.

• Turn ON the POT and NOT

signals.

• Disable them in the settings

when the POT and NOT sig-

nals are not used.

The motor power cable is wired

incorrectly.

Check the wiring. Wire correctly.

The encoder cable is wired

incorrectly.

Power is not supplied. Check the power supply and

the 7-segment display.

Turn ON the power.

Check the voltage between the

power terminals.

Wire the power-ON circuit cor-

rectly.

The Servo Drive is broken

down.

--- Replace the Servo Drive.

The Servomotor oper-

ates momentarily, but

then it does not oper-

ate after that.

The position commands given

are too little.

Check the position data and the

electronic gear ratio at the host

controller.

Set the correct data.

The motor power cable is wired

incorrectly.

Check the wiring of the motor

power cable’s phases U, V, and

W.

Wire correctly.

The encoder cable is wired

incorrectly.

Check the encoder cable’s wir-

ing.

Wire correctly.

The Servomotor

rotates without a com-

mand.

There are inputs of small val-

ues in velocity control mode.

Check if there is an input in

velocity control mode.

Set the velocity command to 0.

Alternatively, change the mode

to position control mode.

The motor power cable is wired

incorrectly.

Check the wiring. Wire correctly.

When the runaway

detection function is

enabled, the

Servomotor rotates

without a command.

The Servomotor power cable is

wired incorrectly, and condi-

tions under which the runaway

detection function cannot work

are satisfied.

Check the wiring. Wire correctly.

Symptom Probable cause Check items Measures

Loading...

Loading...