4-3

4-1 Installation Conditions

4

System Design

Servomotors

Operating Environment

The environment in which the Servomotor is operated must meet the following conditions.

Operating the Servomotor outside of the following ranges may result in malfunction of the

Servomotor.

Ambient operating temperature: 0 to 40°C

Ambient operating humidity: 85% RH max. (with no condensation)

Atmosphere: No corrosive gases.

Impact and Load

The Servomotor is resistant to impacts of up

to 98 m/s

2

. Do not apply heavy impacts or

loads during transportation, installation, or

removal.

When transporting, hold the Servomotor

body itself, and do not hold the Encoder,

Cable, or connector areas. Doing so may

damage the Servomotor.

Always use a pulley remover to remove

pulleys, couplings, or other objects from the

shaft.

Secure cables so that there is no impact or

load placed on the cable connector areas.

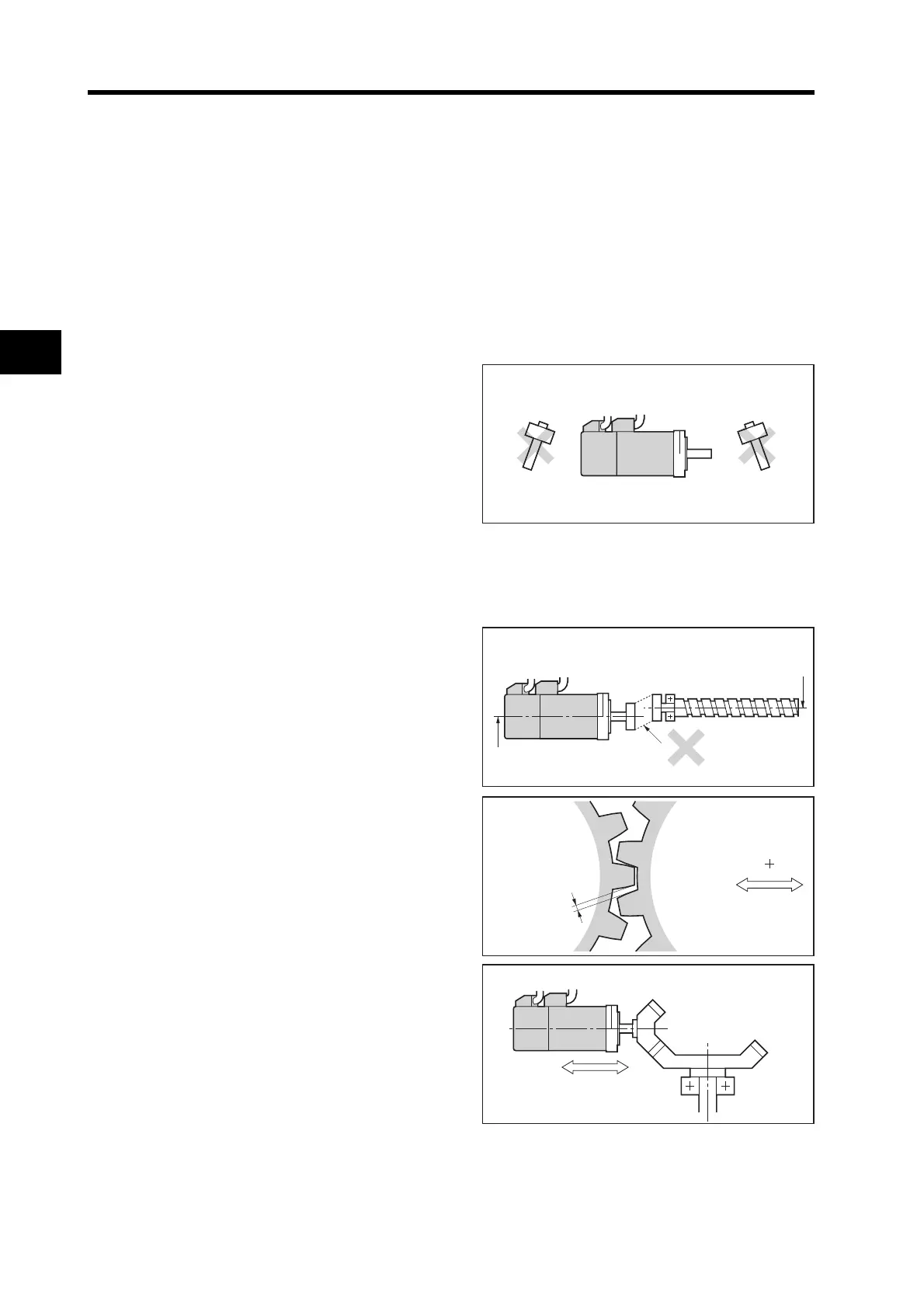

Connecting to Mechanical Systems

The axial loads for Servomotors are

specified in Characteristics on page 3-17. If

an axial load greater than that specified is

applied to a Servomotor, it will reduce the

service life of the motor bearings and may

break the motor shaft.

When connecting to a load, use couplings

that can sufficiently absorb mechanical

eccentricity and declination.

For spur gears, an extremely large radial

load may be applied depending on the gear

precision. Use spur gears with a high degree

of precision (for example, JIS class 2: normal

line pitch error of 6 μm max. for a pitch circle

diameter of 50 mm).

If the gear precision is not adequate, allow

backlash to ensure that no radial load is

placed on the motor shaft.

Bevel gears will cause a load to be applied in

the thrust direction depending on the

structural precision, the gear precision, and

temperature changes. Provide appropriate

backlash or take other measures to ensure

that a thrust load larger than the specified

level is not applied.

Do not put rubber packing on the flange

surface. If the flange is mounted with rubber

packing, the motor flange may crack under

the tightening force.

Make

moveable.

Bevel gear

Structure in which

the distance between

shafts adjustable.

Backlash

Servomotor shaft

center line

Ball screw center line

Do not offset center linesDo not offset center lines.Do not offset center lines.

Loading...

Loading...