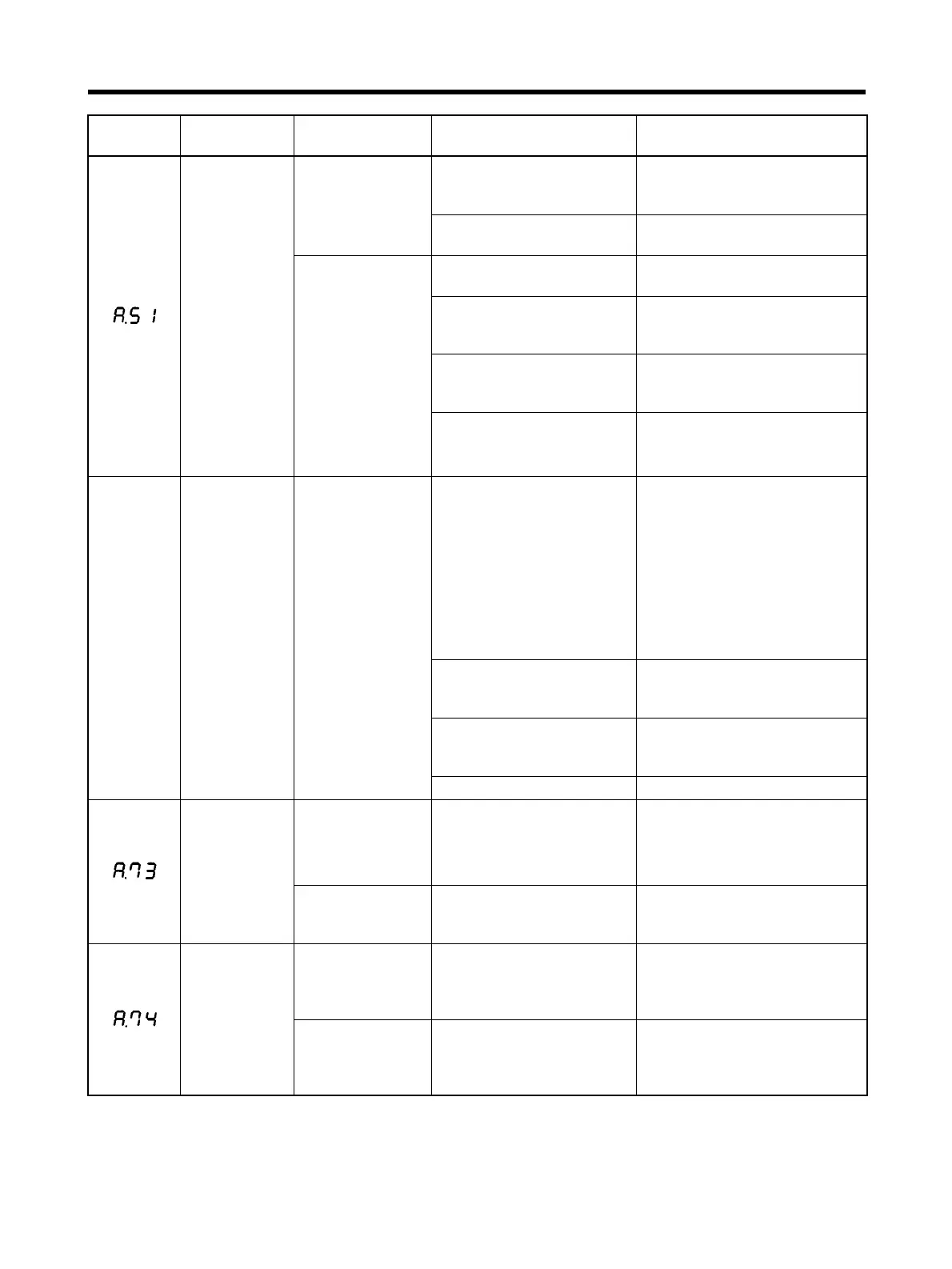

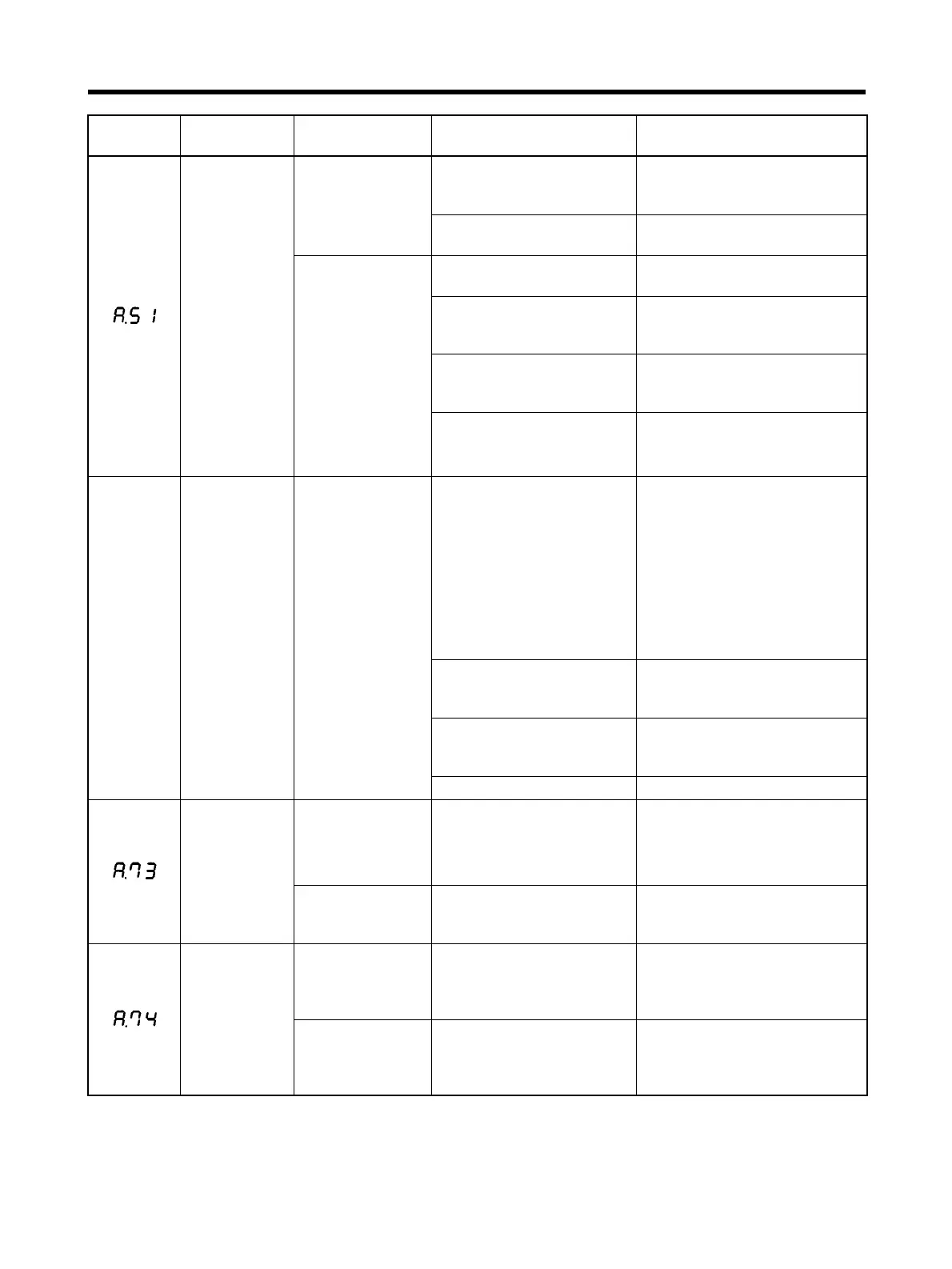

Chapter 5

5-9

Troubleshooting

Overspeed Occurs when the

servo is ON.

Encoder signal between

controllers is wired incor-

rectly.

Rewire correctly.

Servomotor power line is

wired incorrectly.

Rewire correctly.

Occurs along with

high-speed rota-

tion when a com-

mand is input.

Position command input

exceeds 4,500 r/min.

Input command values cor-

rectly.

Pn202 and Pn203 (elec-

tronic gear ratio) setting is

too large.

Set the parameters correctly.

Resolution setting switch

(switches 4 and 5) setting is

too low.

Reset the switches correctly.

Rotation limit has been

exceeded due to over-

shooting.

Adjust the gain.

Lower the maximum specified

speed.

Overload Occurs during

operation.

Running at over 120% of

rated torque (effective

torque).

Repair the Servomotor shaft if

it is locked.

If the Servomotor power line is

wired incorrectly, rewire it cor-

rectly.

Lighten the load.

Lengthen the acceleration and

deceleration times.

Adjust the gain.

Power supply voltage has

fallen.

Check the power supply volt-

age, and lower to within toler-

ance range.

Servomotor winding is

burned out.

Check the winding resistance.

Replace the Servomotor if the

winding is burned out.

Servo Driver is burned out. Replace the Servo Driver.

Dynamic

brake over-

load

Occurs when the

servo is turned

OFF after operat-

ing.

Energy required for stop-

ping exceeds the dynamic

brake resistor tolerance.

Lower the rotation speed.

Reduce the load inertia.

Reduce the frequency of

dynamic brake use.

Occurs when the

power supply is

turned ON.

Control panel error Replace the Servo Driver.

Inrush resis-

tance overload

Occurs when the

main circuit power

supply is turned

ON.

The frequency by which

main-circuit power supply is

turned ON and OFF

exceeds 5 times/min.

Reduce the frequency by which

the main circuit power supply is

turned ON and OFF.

Occurs when the

control circuit

power supply only

is turned ON.

Control panel error Replace the Servo Driver.

Display Error Status when

error occurs

Cause of error Countermeasures

a.7 0

Loading...

Loading...