OIL

SYSTEM

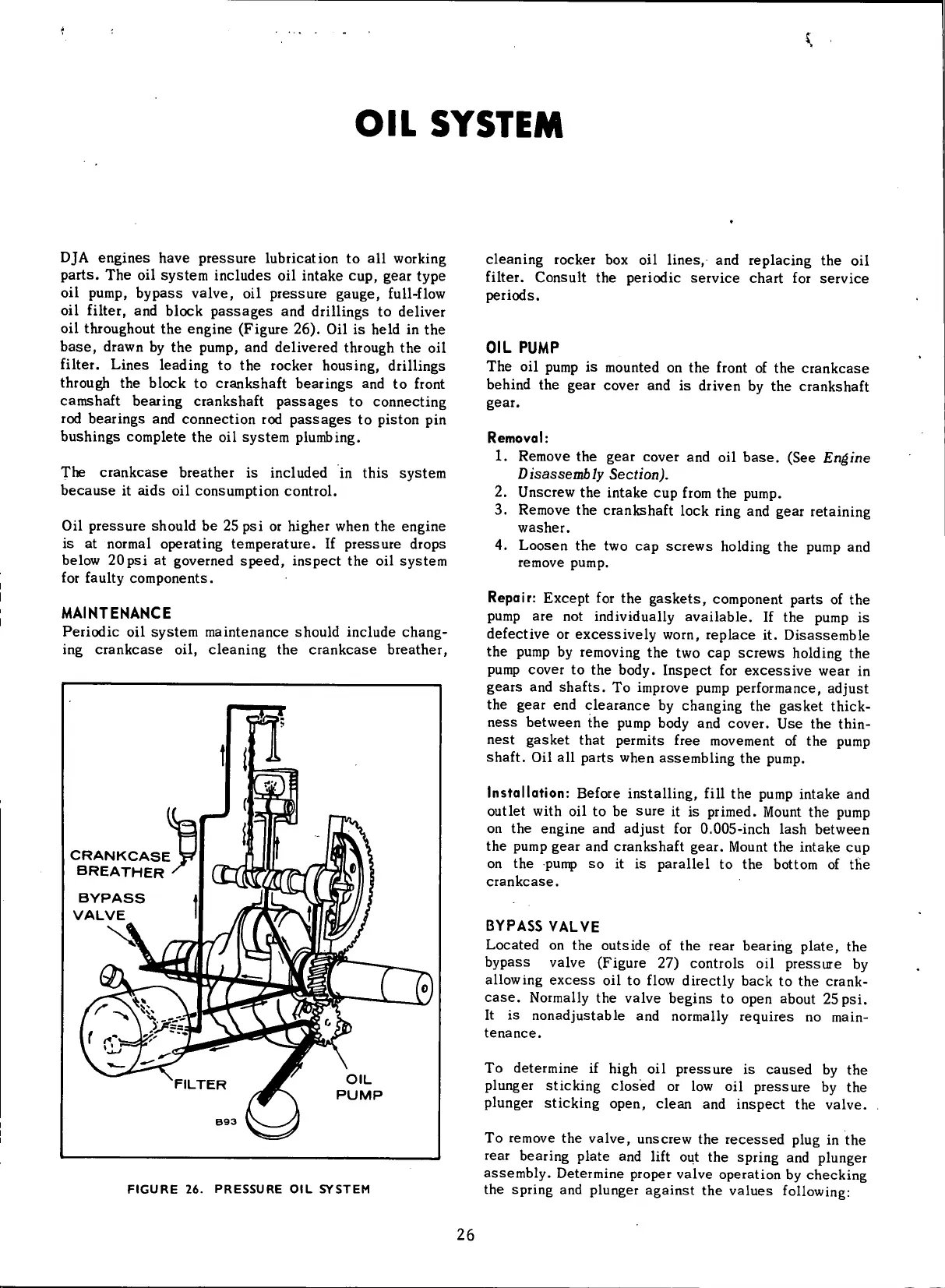

DJA

engines

have

pressure

lubrication to all

working

parts. The oil system includes oil intake cup,

gear

type

oil

pump,

bypass

valve, oil

pressure

gauge,

full-flow

oil

filter,

and block

passages

and

drillings

to deliver

oil

throughout the engine (Figure 26). Oil is held in the

base,

drawn by the pump, and delivered through the oil

filter.

Lines leading to the rocker housing,

drillings

through

the block to crankshaft bearings and to

front

camshaft bearing crankshaft

passages

to connecting

rod

bearings and connection rod

passages

to piston pin

bushings complete the oil system plumbing.

The

crankcase

breather is included in this system

because

it aids oil consumption control.

Oil

pressure

should be 25 psi or higher when the engine

is

at normal operating temperature. If

pressure

drops

below

20psi at governed

speed,

inspect the oil system

for

faulty

components.

MAINTENANCE

Periodic oil system maintenance should include chang-

ing

crankcase

oil, cleaning the

crankcase

breather,

CRANKCASE

BREATHER

BYPASS

VALVE

OIL

PUMP

FIGURE

26.

PRESSURE

OIL

SYSTEM

cleaning rocker box oil lines, and replacing the oil

filter.

Consult the periodic service chart for service

periods.

OIL

PUMP

The oil pump is mounted on the

front

of the

crankcase

behind

the

gear

cover and is driven by the crankshaft

gear.

Removal:

1. Remove

the

gear cover

and oil

base.

(See

Engine

Disassembly Section).

2.

Unscrew the intake cup

from

the pump.

3. Remove the crankshaft

lock

ring

and

gear

retaining

washer.

4.

Loosen the two cap screws holding the pump and

remove pump.

Repair: Except for the

gaskets,

component parts of the

pump are not

individually

available. If the pump is

defective or excessively

worn,

replace it. Disassemble

the pump by removing the two cap screws holding the

pump cover to the body. Inspect for excessive wear in

gears

and shafts. To improve pump performance, adjust

the

gear

end

clearance

by changing the

gasket

thick-

ness

between the pump body and cover. Use the

thin-

nest

gasket

that permits free movement of the pump

shaft. Oil all parts when assembling the pump.

Installation:

Before

installing,

fill

the pump intake and

outlet

with

oil to be

sure

it is primed. Mount the pump

on

the engine and adjust for 0.005-inch lash between

the pump

gear

and crankshaft

gear.

Mount the intake cup

on

the punp so it is parallel to the bottom of the

crankcase.

BYPASS

VALVE

Located

on the outside of the

rear

bearing plate, the

bypass

valve (Figure 27) controls oil

pressure

by

allowing

excess

oil to

flow

directly back to the crank-

case.

Normally

the valve begins to open about 25 psi.

It

is nonadjustable and normally requires no main-

tenance.

To

determine if

high

oil

pressure

is

caused

by the

plunger sticking closed or low oil

pressure

by the

plunger sticking open, clean and inspect the valve.

To

remove the valve, unscrew the

recessed

plug in the

rear

bearing plate and

lift

out the spring and plunger

assembly. Determine proper valve operation by checking

the spring and plunger against the values

following:

26

Loading...

Loading...