OIL

SYSTEM

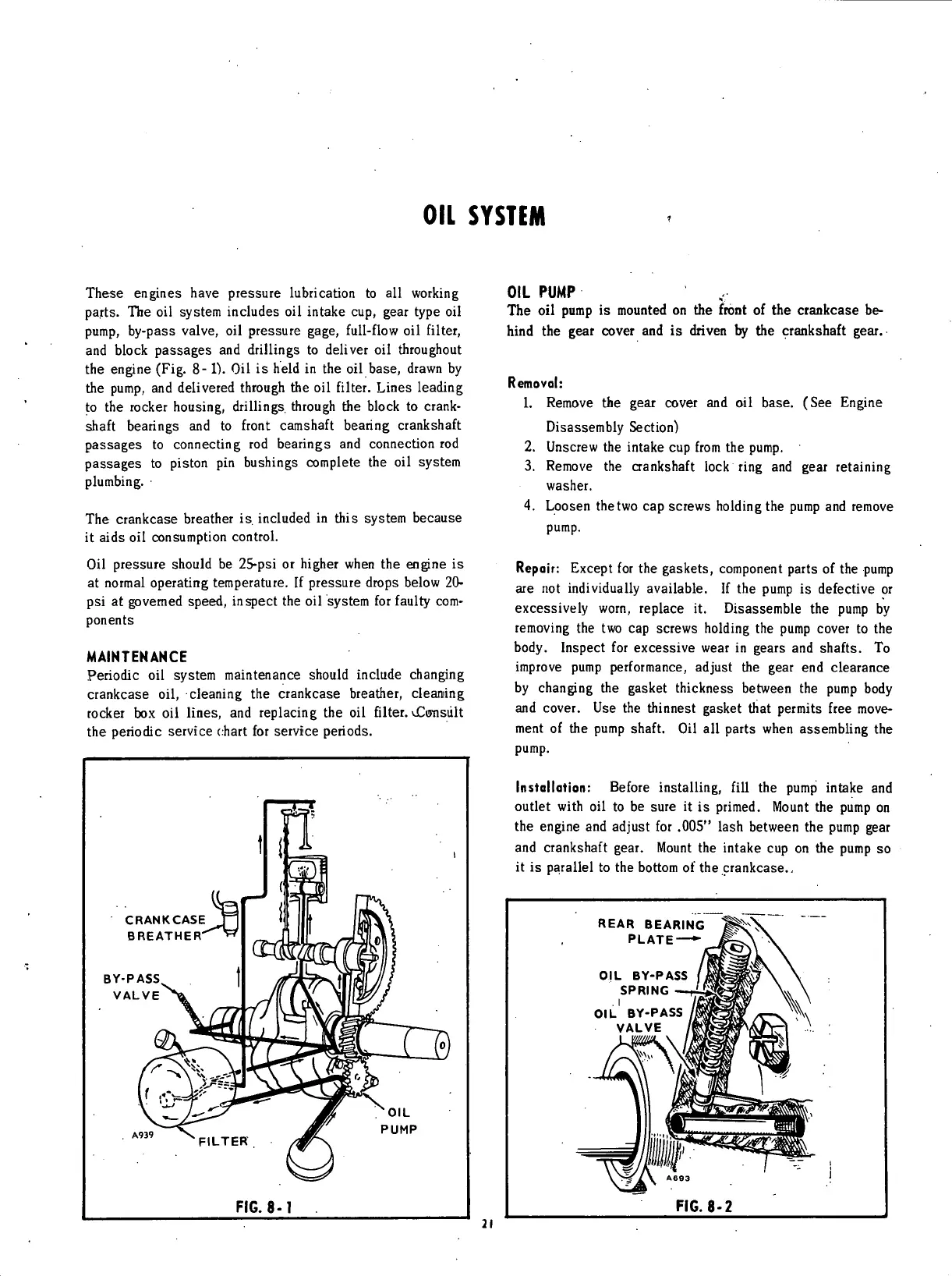

These

engines have

pressure

lubrication

to all

working

parts. The oil system includes oil intake cup,

gear

type oil

pump,

by-pass

valve, oil

pressure

gage,

full-flow

oil

filter,

and block

passages

and

drillings

to deliver oil throughout

the engine

(Fig.

8-

D.

Oil is held in the oil

base,

drawn by

the pump, and delivered through the

oil

filter.

Lines leading

to

the rocker housing,

drillings,

through the block to crank-

shaft bearings and to

front

camshaft bearing crankshaft

passages

to connecting rod bearings and connection rod

passages

to piston pin bushings complete the oil system

plumbing.

The crankcase breather is. included in this system

because

it

aids

oil

consumption

control.

Oil

pressure

should be 25-psi or higher when the engine is

at normal operating temperature. If

pressure

drops below 20-

psi

at govemed

speed,

inspect the

oil

system

for

faulty

com-

ponents

MAINTENANCE

Periodic

oil system maintenance should include changing

crankcase oil, cleaning the crankcase breather, cleaning

rocker

box oil lines, and replacing the oil

filter.

vJCcmsiilt

the periodic service chart for service periods.

CRANKCASE

F~

BREATHER^"^

BY-PASS

N

VALVE

A939

OIL

PUMP

FIG.

8-1

OIL

PUMP

The

oil pump is mounted on the front of the crankcase be-

hind

the gear cover and is driven by the crankshaft gear.

Removal:

1.

Remove the

gear

cover and oil

base.

(See Engine

Disassembly Section)

2.

Unscrew the intake cup

from

the pump.

3. Remove the crankshaft

lock

ring

and

gear

retaining

washer.

4.

Loosen

the

two

cap screws

holding

the pump and remove

pump.

Repair: Except

for

the

gaskets,

component parts of the pump

are not

individually

available. If the pump is defective or

excessively

worn,

replace it. Disassemble the pump by

removing

the two cap screws

holding

the pump cover to the

body.

Inspect for excessive wear in

gears

and shafts. To

improve

pump performance, adjust the

gear

end clearance

by

changing the gasket thickness between the pump body

and cover. Use the thinnest gasket that permits free move-

ment of the pump shaft. Oil all parts when assembling the

pump.

Installation:

Before

installing,

fill

the pump intake and

outlet

with

oil to be

sure

it is primed.

Mount

the pump on

the engine and adjust for .005" lash between the pump

gear

and crankshaft

gear.

Mount

the intake cup on the pump so

it

is parallel to the

bottom

of the crankcase..

21

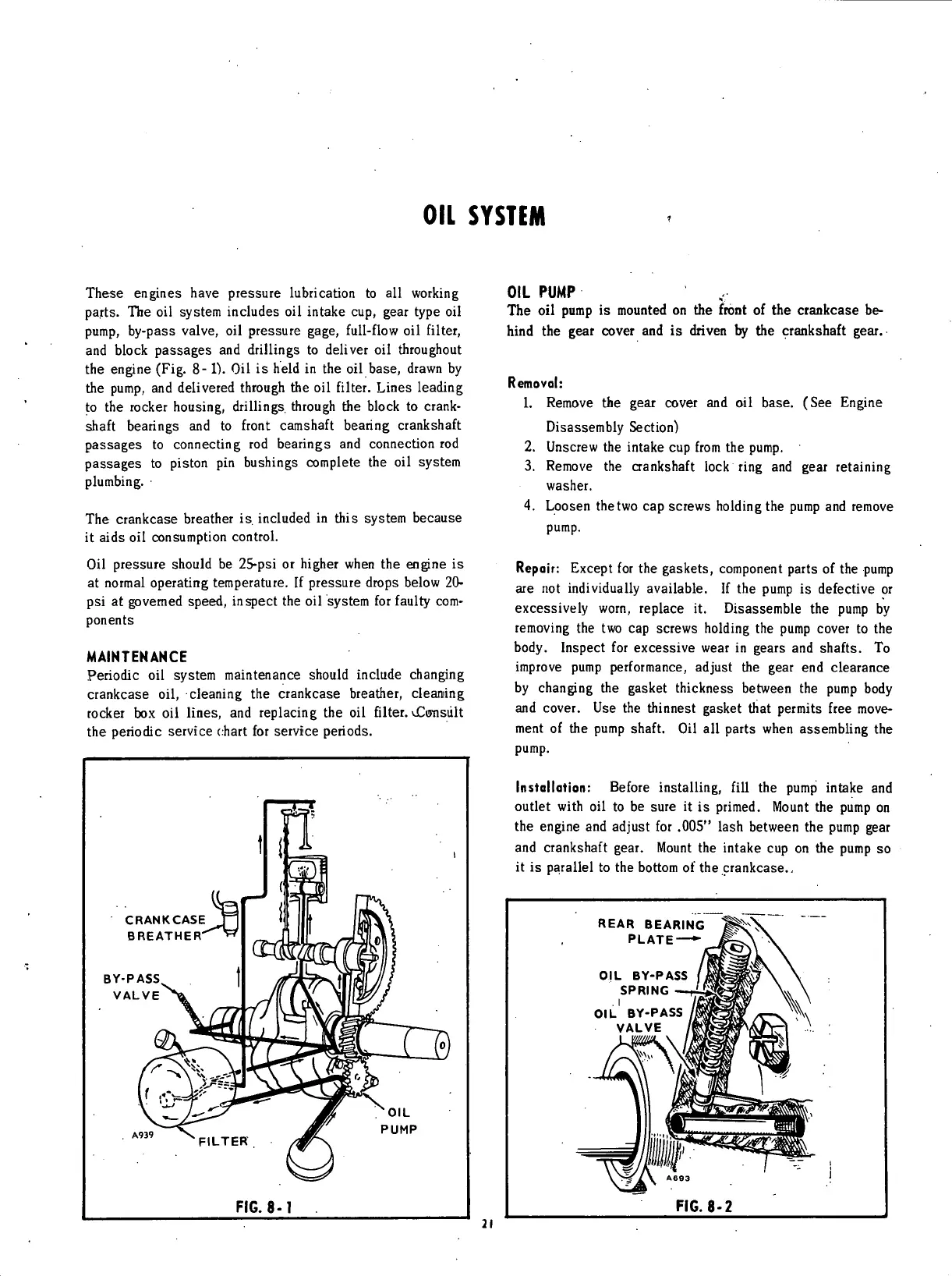

REAR

BEARING

PLATE-

OIL

BY-PASS

SPRING

OIL

BY-PASS

VALVE

FIG.

8-2

Loading...

Loading...