GOVERNOR

SYSTEM

The

purpose of the governor is to

maintain

a constant engine

speed

during

changes

in

power demands.

A

governor responds

to changes by varying the throttle position.

Three

types of

governors are used: The constant speed governor which is

standard,

the two-speed

and

variable

speed governors which

are

optional.

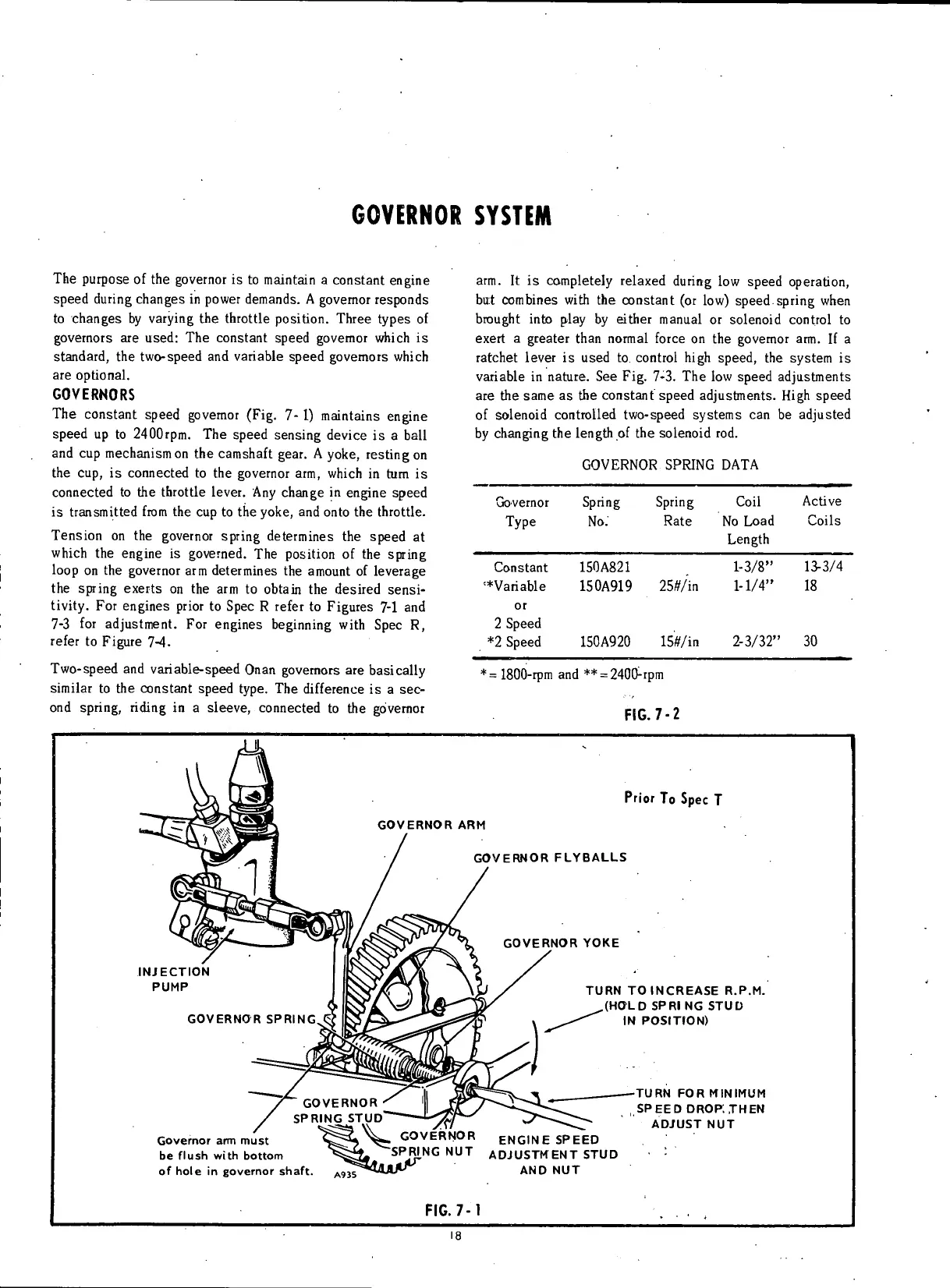

GOVERNORS

The

constant speed governor (Fig. 7-1) maintains engine

speed up to 2400rpm. The speed sensing device is a

ball

and

cup

mechanism

on

the camshaft

gear.

A

yoke,

resting

on

the cup, is connected to the governor arm,

which

in tum is

connected to the throttle lever.

Any

change in engine speed

is

transmitted

from

the cup to the

yoke,

and onto the

throttle.

Tension

on the governor spring determines the speed at

which

the engine is governed. The

position

of the spring

loop

on the governor arm determines the amount of leverage

the spring exerts on the arm to obtain the desired sensi-

tivity.

For engines

prior

to

Spec

R refer to Figures 7-1 and

7-3 for adjustment. For engines beginning

with

Spec

R,

refer

to Figure 7-4.

Two-speed

and variable-speed Onan governors are basically

similar

to the constant speed type. The

difference

is a

sec-

ond

spring,

riding

in a sleeve, connected to the governor

arm.

It is completely relaxed

during

low speed operation,

but

combines

with

the constant (or low) speed.spring when

brought

into

play by either manual or solenoid

control

to

exert a greater than normal force on the governor arm. If a

ratchet lever is used to

control

high

speed,

the system is

variable

in nature. See

Fig.

7-3. The

low

speed adjustments

are the

same

as the constant speed adjustments.

High

speed

of

solenoid

controlled

two-speed systems can be adjusted

by

changing

the

length

of the solenoid rod.

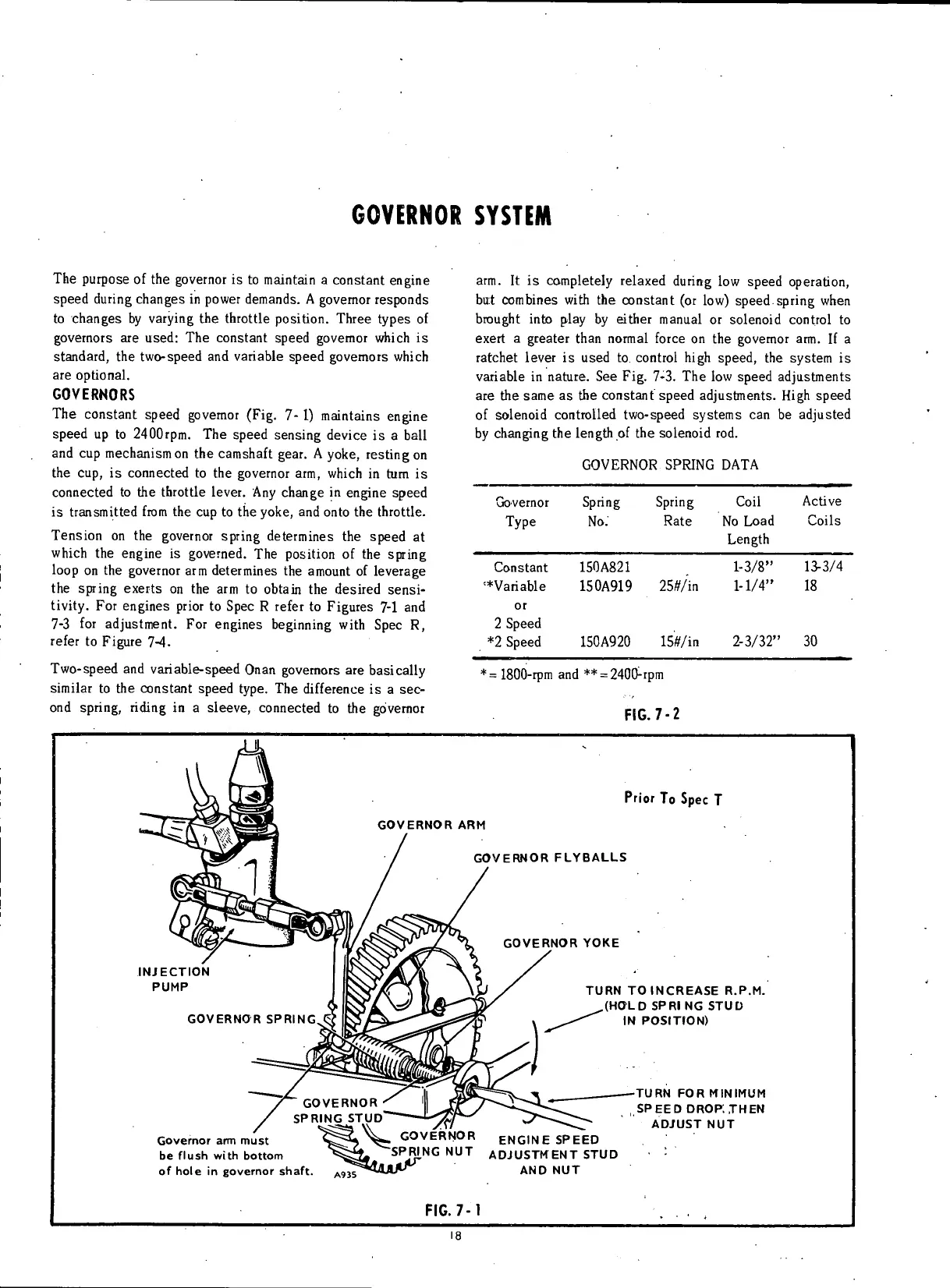

GOVERNOR

SPRING

DATA

Governor

Type

Spring

No.

Spring

Rate

Coil

No

Load

Length

Active

Coils

Constant

'•Variable

or

2

Speed

*2

Speed

150A821

150A919

25#/in

1-3/8"

1-1/4"

13-3/4

18

Constant

'•Variable

or

2

Speed

*2

Speed

150A920

15#/in

2-3/32"

30

*=

1800-rpm

and

**

=

2400

:

rpm

FIG.

7-2

INJECTION

PUMP

GOVERNOR

ARM

GOVERNOR FLYBALLS

GOVERNOR YOKE

Prior

To

Spec

T

TURN

TO

INCREASE R.P.M.

..(HOLD SPRI

NG

STUD

IN POSITION)

TURN

FOR

MINIMUM

SPEED DROP. THEN

ADJUST

NUT

Governor

arm

must

be flush with bottom

of hole

in

governor shaft.

ENGINE SPEED

ADJUSTMENT STUD

AND

NUT

FIG.

7-1

18

Loading...

Loading...