FLYWHEEL

ALTERNATOR

There are

four

major components in the battery charging

system. (I) a permanent magnet on the

flywheel

provides a

rotating

magnetic

field;

(2) a group of coils mounted behind

the

flywheel

on the

gear

cover cut the

field

to produce a

voltage;

(31 a

2-step

mechanical regulator controls the ac

voltage

to the

rectifier,

and (4) a

full

wave

rectifier

con-

verts the regulated ac to dc

for

battery charging.

The permanent magnet

(rotor)

is held to the

flywheel

by

screws. It is

fully

supported by the

flywheel

and therefore

has no bearings. The stator windings are encapsulated in

an epoxy resin for protection

from

moisture.

Cooling

of

the stator is

from

special

fins

on the rotor. The

rectifier

is

located inside the blower housing and cooled by incoming

engine air. A fuse between the

rectifier

and ground pro-

tects the rectifiers

from

destruction should the battery be

connected in the

circuit with

reversed

polarity.

The mech-

anical

regulator cannot tolerate normal

vibration

of the

engine, so it must be mounted on a

separate

panel.

The alternator develops

two

different

rates

of current output.

The smaller output is connected in the charge

circuit

for a

continuous

low

rate charge. The larger output is controlled

by

the mechanical regulator,

which

has two relays, one of

which

is voltage sensitive. When battery voltage

falls

and

the voltage sensitive relay is de-energized, contacts close

to

provide a

circuit

to the other relay,

which

makes a

circuit

for

the

high

rate charge. See Fig. 10-2

wiring

schematic.

The voltage at

which

the sensitive relay is energized varies

with

the temperature.

The

final

result is a charge rate of 12-amperes

into

a 70-amp

hour,

12-volt

battery when the engine is

running

at 1,800-rpm.

The maximum continuous dc load is

limited

to 10-amperes

at 1,800-rpm. Reverse current through the

rectifiers

is 5 to

10-milliamperes,

so no special reverse current protection is

"needed. The engine should not be run

while

the battery is

disconnected, but if the battery is

accidentally

disconnected,

the system

will

not be damaged.

MAINTENANCE

There are neither

brushes

nor bearings in this system so

maintenance is

limited

to keeping the components in good

condition.

When the

flywheel

is off, clean the rotor and

stator and check the wires. In general, see that all connec-

tions

are

secure

and all components clean. If the alternator

is

operating

satisfactorily,

do not tamper

with

it.

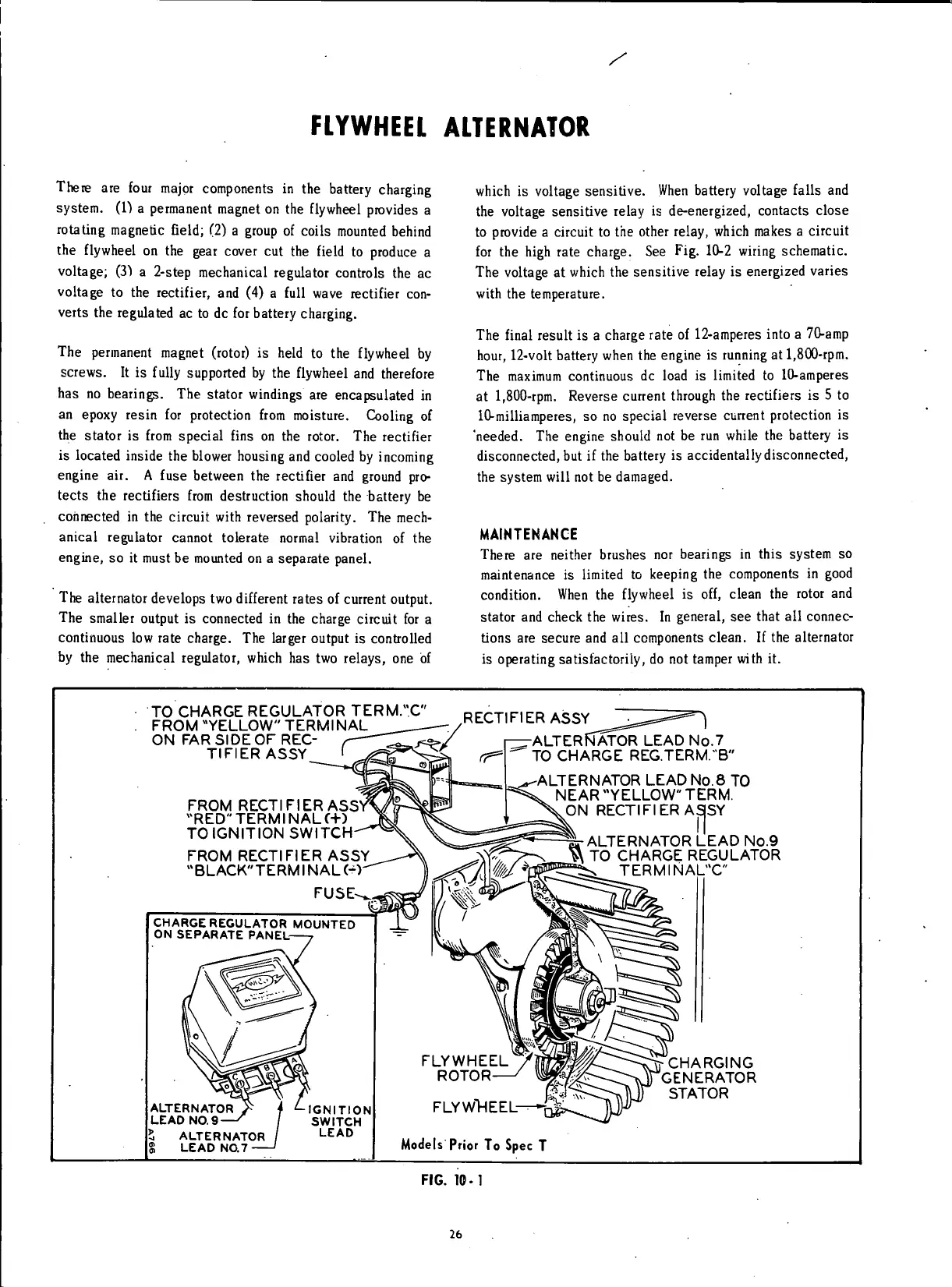

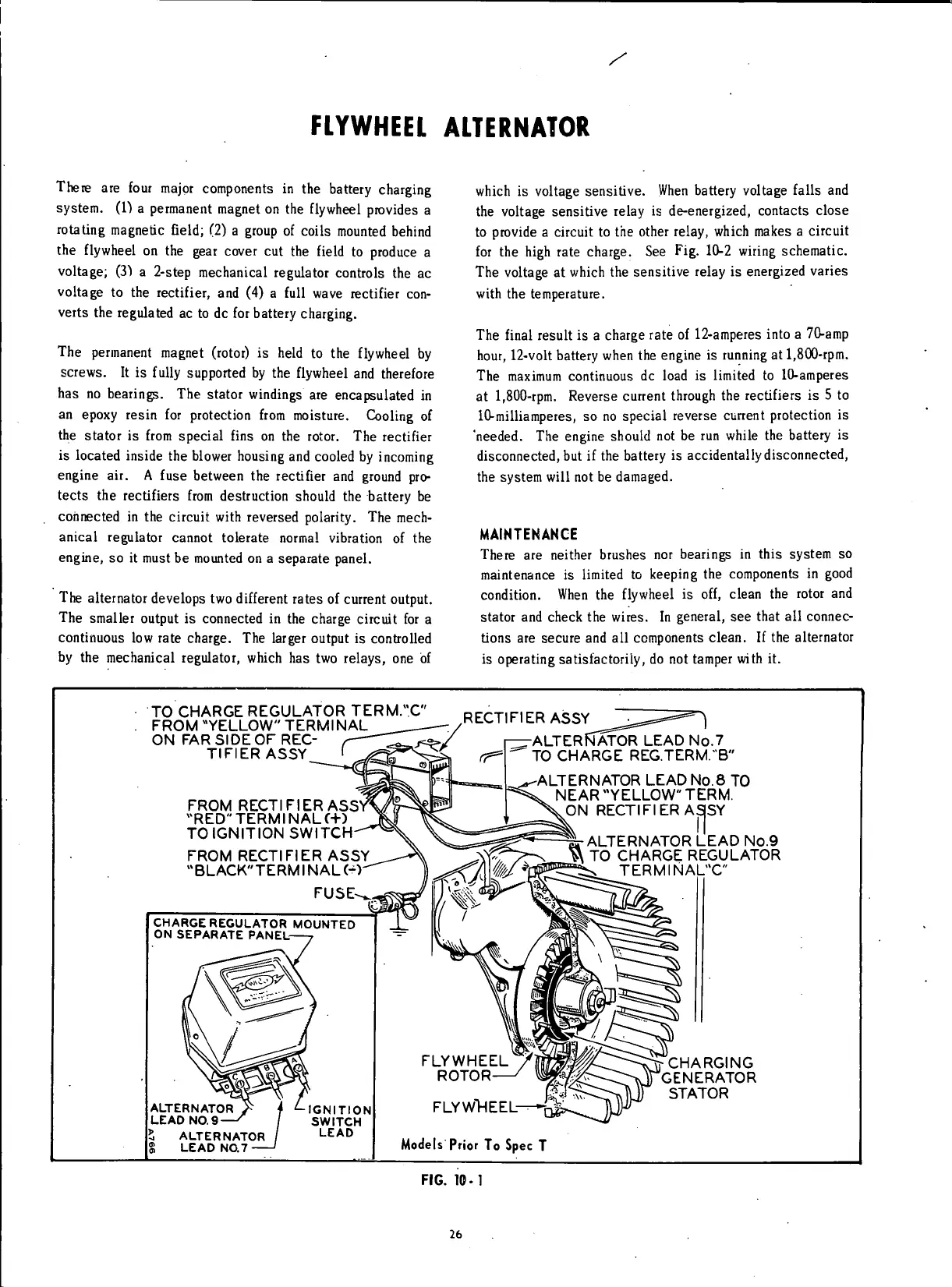

TO CHARGE REGULATOR TERM.X

FROM "YELLOW" TERMINAL

ON FAR SIDE OF REC-

TIFIER ASSY

FROM RECTIFIER ASSV

"RED"

TERM

I

NAL (+)

TO IGNITION SWITCH-

FROM RECTIFIER ASSY

"BLACK" TERMINALS)'

FUSE-

CHARGE REGULATOR MOUNTED

ON SEPARATE PANEL-

ALTERNATOR

LEAD

NO.9

5 ALTERNATOR

3 LEAD

NO.7

IGNITION

SWITCH

LEAD

RECTIFIER ASSY^J^^***"

1

>/ r^rALTERfWOR LEAD

No.7

-

— "

TO CHARGE REG.TERM. 'B"

-ALTERNATOR LEAD No.8

TO

NEAR "YELLOW" TERM.

ON RECTIFIER AS|SY

CM-

ALTERNATOR LEAD

No.9

^

TO

CHARGE REGULATOR

TERMINA

FLYWHEEL

ROTOR-

FLYWHEEL-

CHARGING

GENERATOR

STATOR

Models Prior

To

Spec

T

FIG.

10-1

26

Loading...

Loading...