ENGINE

DISASSEMBLY

CYLINDER

HEAD,

VAIVES

The

cylinder

head assembly has

alloy

hardened faced valves,

release

type rotators,

alloy

hardened inserts, guides, rocker

arms,

injection

nozzle and

glow

plug.

The push rods run

through

shields.

MAINTENANCE

Check the valve

clearances

at regular intervals. In

addition,

dean the combustion chamber 'and valve

seats

at regular

intervals.

VALVE

CLEARANCE

Check valve clearance when the engine is at

room

temper-

ature (about 70

o

n.

1.

Tum the

flywheel

until

the

cylinder

is on its compres-

sion

stroke. Use a socket wrench on the

flywheel

screw

hex head.

To

determine

ifthe

cylinder

is in its compression stroke,

observe the action of the push rods as the engine is

rotated

in a clockwise

direction.

The exhaust valve

push rod

will

be in its lowest

position

and the intake

valve

push rod

will

be

moving

downward. As the piston

reaches

top dead center, the

flywheel

timing

mark should

be aligned

with

the

timing

pointer and the valve push

rods stationary.

2.

Now

turn

the

flywheel

clockwise for an additional 10

to

45-degrees.

There is no

timing

mark for this

position

so it must be estimated.

With

the piston located in this

position,

it

will

be in its power stroke

with

both valves

completely

closed.

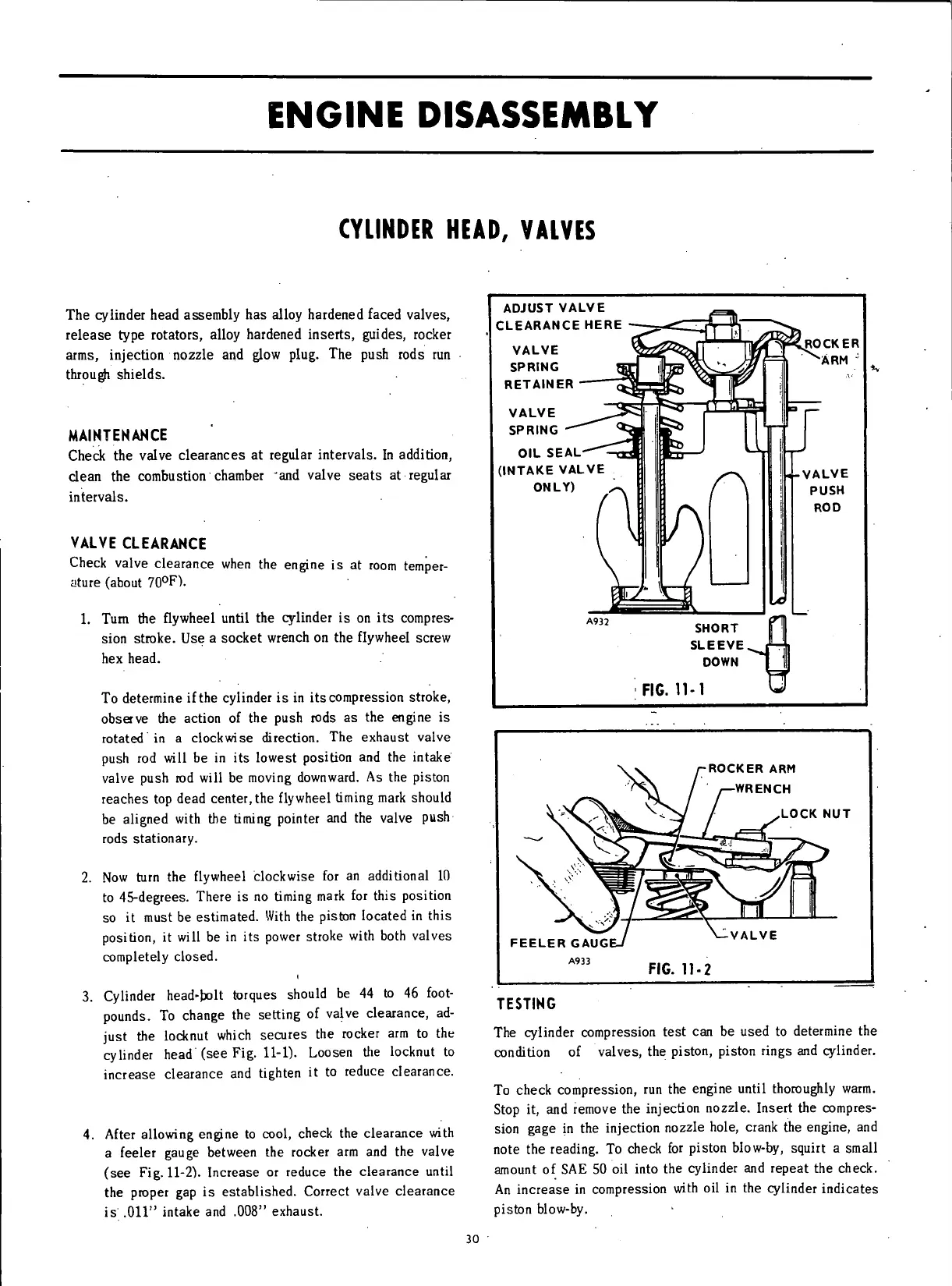

3.

Cylinder

head-bolt torques should be 44 to 46

foot-

pounds. To

change

the setting of valve clearance, ad-

just

the

locknut

which

secures

the rocker arm to the

cylinder

head (see Fig. 11-1). Loosen the

locknut

to

increase clearance and tighten it to reduce clearance.

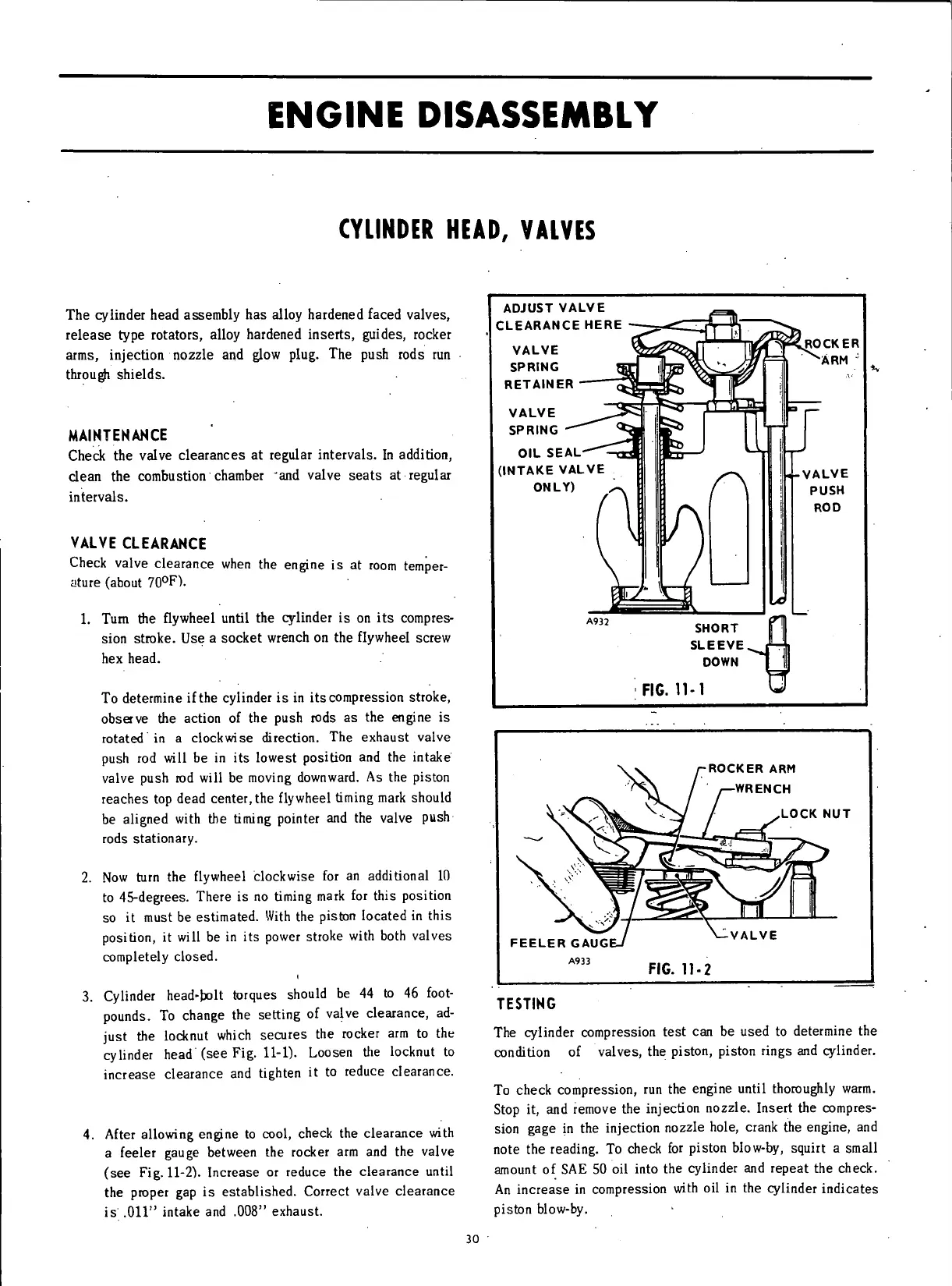

4.

After

allowing

engine to

cool,

check the clearance

with

a feeler

gauge

between the rocker arm and the valve

(see

Fig.

11-2).

Increase or reduce the clearance

until

the proper gap is established. Correct valve clearance

is

.011" intake and .008" exhaust.

ADJUST

VALVE

CLEARANCE

HERE

VALVE

SPRING

RETAINER

VALVE

SPRING

OIL

SEAL-

(INTAKE

VALVE

ONLY)

f

LROCKER

"ARM

;

FIG.

11-1

ROCKER

ARM

WRENCH

LOCK

NUT

FEELER

GAUG

A933

VALVE

FIG.

11-2

TESTING

The

cylinder

compression test can be used to determine the

condition

of valves, the piston, piston rings and cylinder.

To

check compression, run the engine

until

thoroughly

warm.

Stop it, and remove the

injection

nozzle. Insert the compres-

sion

gage

in the

injection

nozzle hole, crank the engine, and

note the reading. To check for piston

blow-by,

squirt a small

amount of SAE 50 oil

into

the

cylinder

and

repeat

the check.

An

increase in compression

with

oil in the

cylinder

indicates

piston

blow-by.

30

Loading...

Loading...