ALTERNATOR TROUBLESHOOTING

Trouble

in the charging system

will

be indicated by a weak

or

discharged battery.

1. Charge battery

and

check

its

condition

to be

sure

battery

is

serviceable. Charging system test requires

a tully

charged

battery.

2.

Connect voltmeter

across

battery - start engine and

operate at 1800 - 3600rpm. The voltmeter should ,

register 13.4 -14.05

volts.

If

voltage is below 13.4volts

install

new output

control,

and retest. Be

sure

output

control

has good clean ground

connection

and the

wire

connector is properly

seated.

'When

meter

reads

14.05

volts

no further testing

is

required. When new output

control

is installed and

meter

does

not register 13.4volt

minimum

then proceed

to

test stator group as

follows:

ay

To

determine if the alternator is charging the battery, use

a

HOvolt

-100 or 150watt

light

bulb in a socket

with

leads.

Disconnect the output

control

and connect the

leads

from

the

lOOvolt

bulb

across

the two

yellow

leads

from

the

alternator. Start .the engine and operate at ISOOrpm. The

light

bulb

will

show a

d

im

light

and at

3600

rpm

the

light

bulb

will

be

fairly

bright.

This method of testing

will

require a charged battery for starting the engine.

If

the

HOvolt light

bulb

does

not indicate a charge, use

an ohmmeter and check out stator

coil

using the

following

procedure

with

engine stopped.

TEST INSTRUMENT

Simpson

Model

260 V.O.M. or equivalent.

Set

voltage selec-

tor switch

to

DC + .

Be

sure test meter

is in

good

condition

and

if

battery powered, that

the

battery

is

good.

Be

sure

your meter

is

zeroed before each

reading

and each time you

change scales.

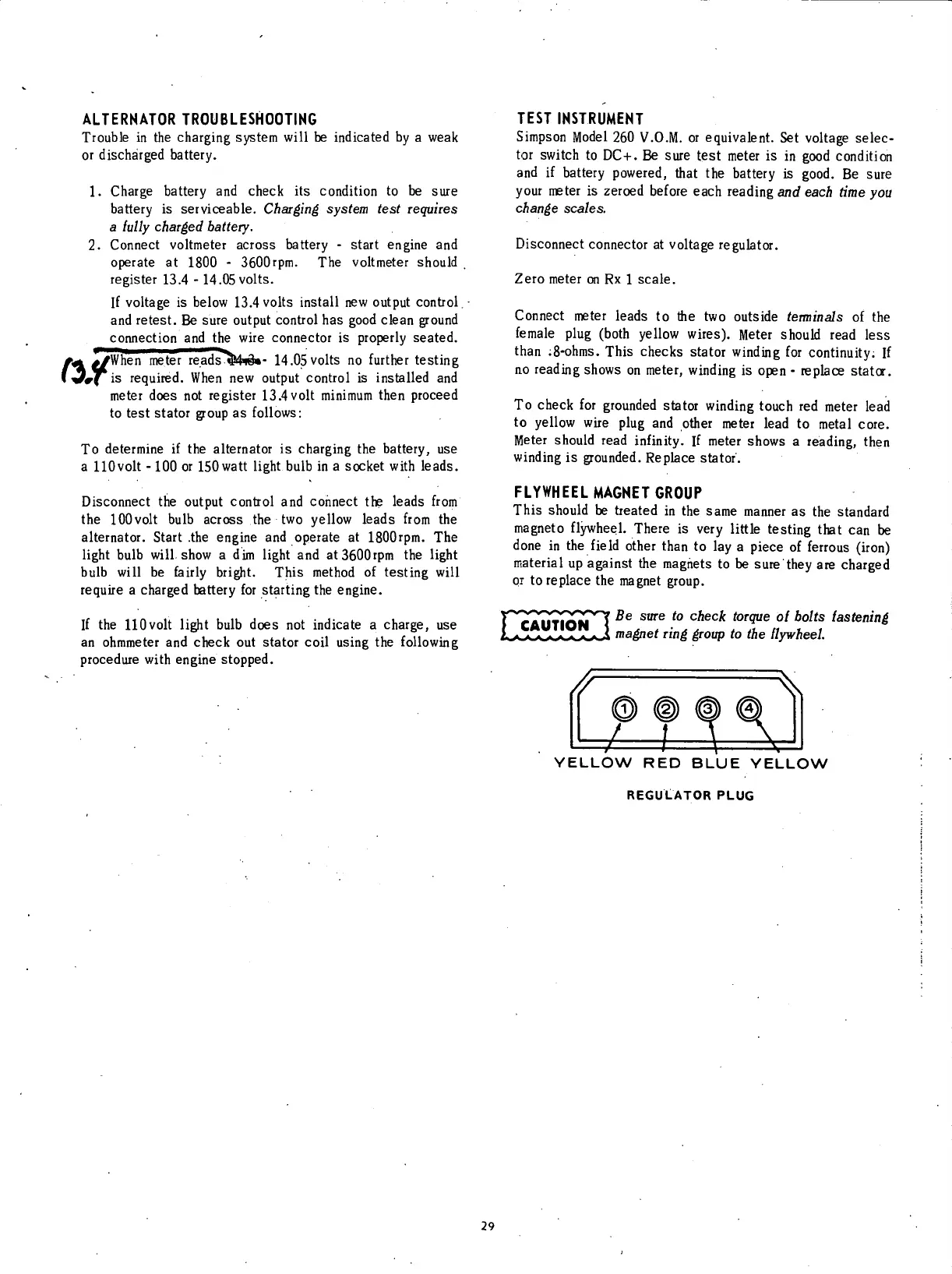

Disconnect connector at voltage regulator.

Zero

meter on Rx 1 scale.

Connect meter

leads

to the two outside terminals of the

female

plug

(both

yellow

wires).

Meter should read

less

than

:8-ohms. This checks stator

winding

for

continuity.

If

no reading shows on meter,

winding

is open - replace

stata.

To

check for grounded stator

winding

touch red meter lead

to yellow wire

plug

and other meter lead to metal core.

Meter

should read

infinity.

If meter shows a reading, then

winding

is grounded. Replace stator.

FLYWHEEL MAGNET GROUP

This

should be treated in the

same

manner as the standard

magneto

flywheel.

There is very

little

testing that can be

done in the

field

other than to lay a piece of ferrous

(iron)

material

up against the magnets to be

sure

they are charged

or

to replace the magnet group.

CAUTION

Be sure

to

check torque

oi

bolts fastening

magnet ring

group

to

the flywheel.

YELLOW

RED

BLUE YELLOW

REGULATOR PLUG

29

Loading...

Loading...