FUEL

SYSTEM

The diesel

fuel

system provides a

means

of

filtering,

trans-

porting

and

delivering fuel

in a

fine

spray to the engine

cylinder

at the correct time for

ignition.

The system con-

sists

of a primary

fuel filter, fuel

transfer pump, secondary

fuel filter, injection

pump and an

injection

nozzle.

The diaphragjn

fuel

transfer pump

which

operates

directly

off

the engine camshaft, draws

fuel from

a supply tank and

delivers it through two

filters

to the

injection

pump. The

injection

pump

meters

fuel

and delivers it, at

high

pres-

sure

to the

injection

nozzle at the correct time for

ignition.

The

injection

nozzle

opens

at a set

fuel

pressure,

delivering

fuel

in a

fine

spray, to the precombustion chamber for

igni-

tion.

The nozzle remains open,

delivering fuel

as

long

as

the

fuel

pressure

remains above the

critical

point.

Caution: Dirt

in the

iuel system

is a

diesel engines worst

enemy.

It is one ol the

major causes

ol

diesel engine

failure. Even

a

tiny piece

ol

dirt

in the

injection system

may stop your unit.

When

opening

any

part

ol the

fuel

system beyond

the

secondary fuel filter, place

all

parts

in

a

pan of

clean diesel fuel

as

they

are

removed. Beiore

installing

new or

used parts, Hush them thoroughly

and

install while still wet.

MAINTENANCE

In

addition to regular service periods,

change

the secondary

fuel filter

cartridge if the engine shows signs of starving

from

lack of

fuel.

Remove the secondary

filter

by removing

the large cap screw in the center of the

filter

cover. Use

care

when replacing the

filter

cartridge to

avoid

getting

dirt into

the

injection

pump

passages.

Extra

fuel

is bled off after

each

injection

cycle by a

fuel

retum

line from

the nozzle. An

adapter

combines the leak-

off

fuel with

the

flow-through fuel from

the

injection

pump.

A

return

line

connected at this point, returns the combined

fuel

back to the

fuel

supply tank.

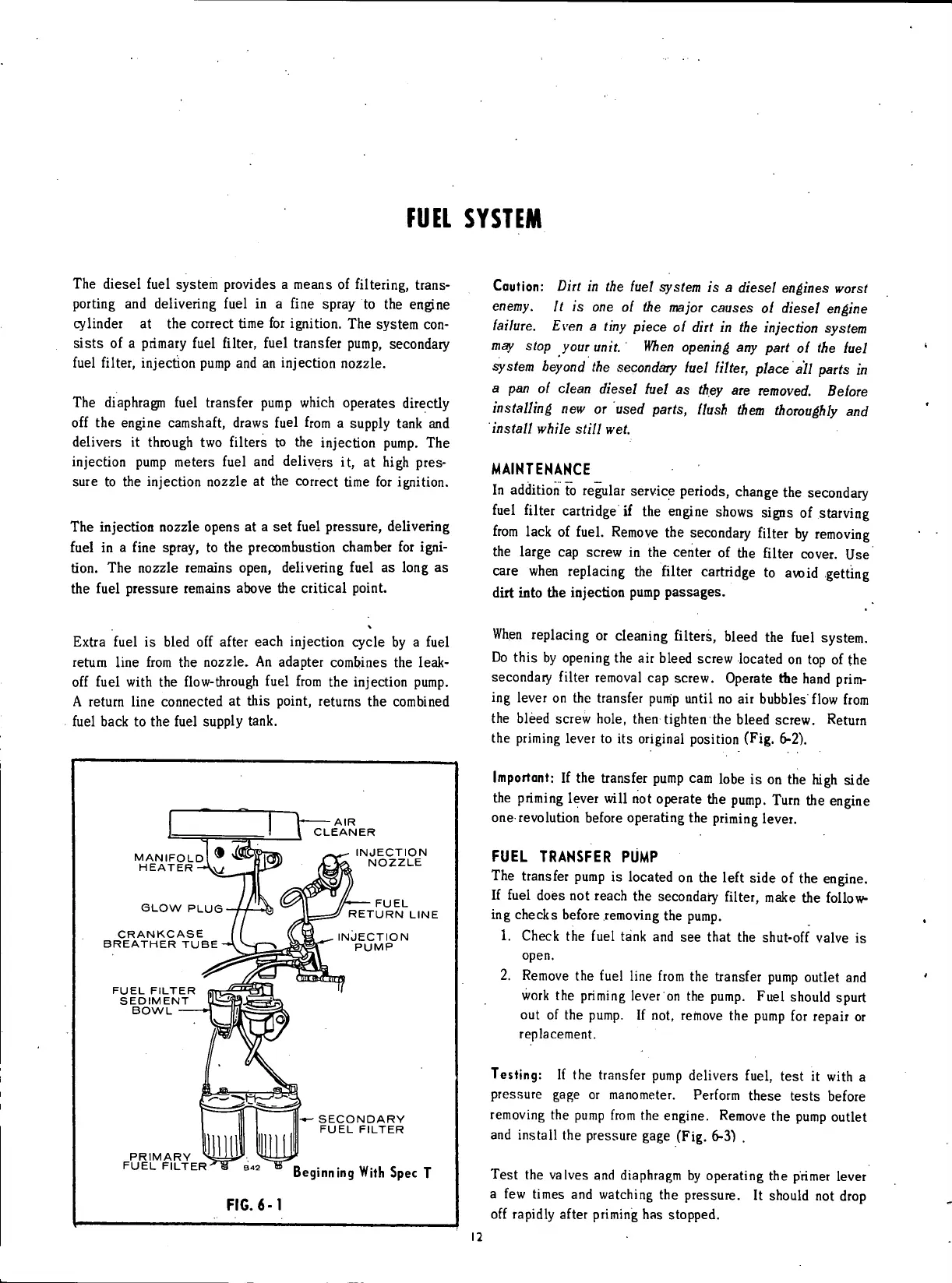

AIR

CLEANER

MANIFOLD

HEATER

6LOW PLUS-

CRANKCASE

BREATHER TUBE

FUEL FILTER

SEDIMENT

BOWL

PRIMARY

FUEL FILTER

INJECTION

NOZZLE

FUEL

RETURN LINE

INJECTION

PUMP

SECONDARY

FUEL FILTER

Beginning With Spec

T

FIG.

6-1

When

replacing or cleaning

filters,

bleed the

fuel

system.

Do

this by opening the air bleed screw located on top of the

secondary

filter

removal cap screw. Operate the hand

prim-

ing

lever on the transfer pump

until

no air bubbles

flow from

the bleed screw hole, then tighten the bleed screw. Return

the

priming

lever to its

original

position

(Fig.

6-2).

Important:

If the transfer pump cam lobe is on the

high

side

the

priming

lever

will

not

operate

the pump.

Turn

the engine

one

revolution

before operating the

priming

lever.

FUEL

TRANSFER

PUMP

The transfer pump is located on the

left

side of the engine.

If

fuel

does

not reach the secondary

filter,

make the

follow-

ing

checks before

removing

the pump.

1.

Check the

fuel

tank and see that the

shut-off

valve is

open.

2.

Remove the

fuel line from

the transfer pump outlet and

work

the

priming

lever on the pump. Fuel should spurt

out

of the pump. If not, remove the pump for repair or

replacement.

Testing:

If the transfer pump delivers

fuel,

test

it

with

a

pressure

gage

or manometer. Perform

these

tests

before

removing

the pump

from

the engine. Remove the pump outlet

and

install

the

pressure

gage

(Fig.

6-3) .

Test the valves and diaphragm by operating the primer lever

a few times and watching the

pressure.

It should not drop

off

rapidly

after

priming

has stopped.

12

Loading...

Loading...