COOLING

SYSTEM

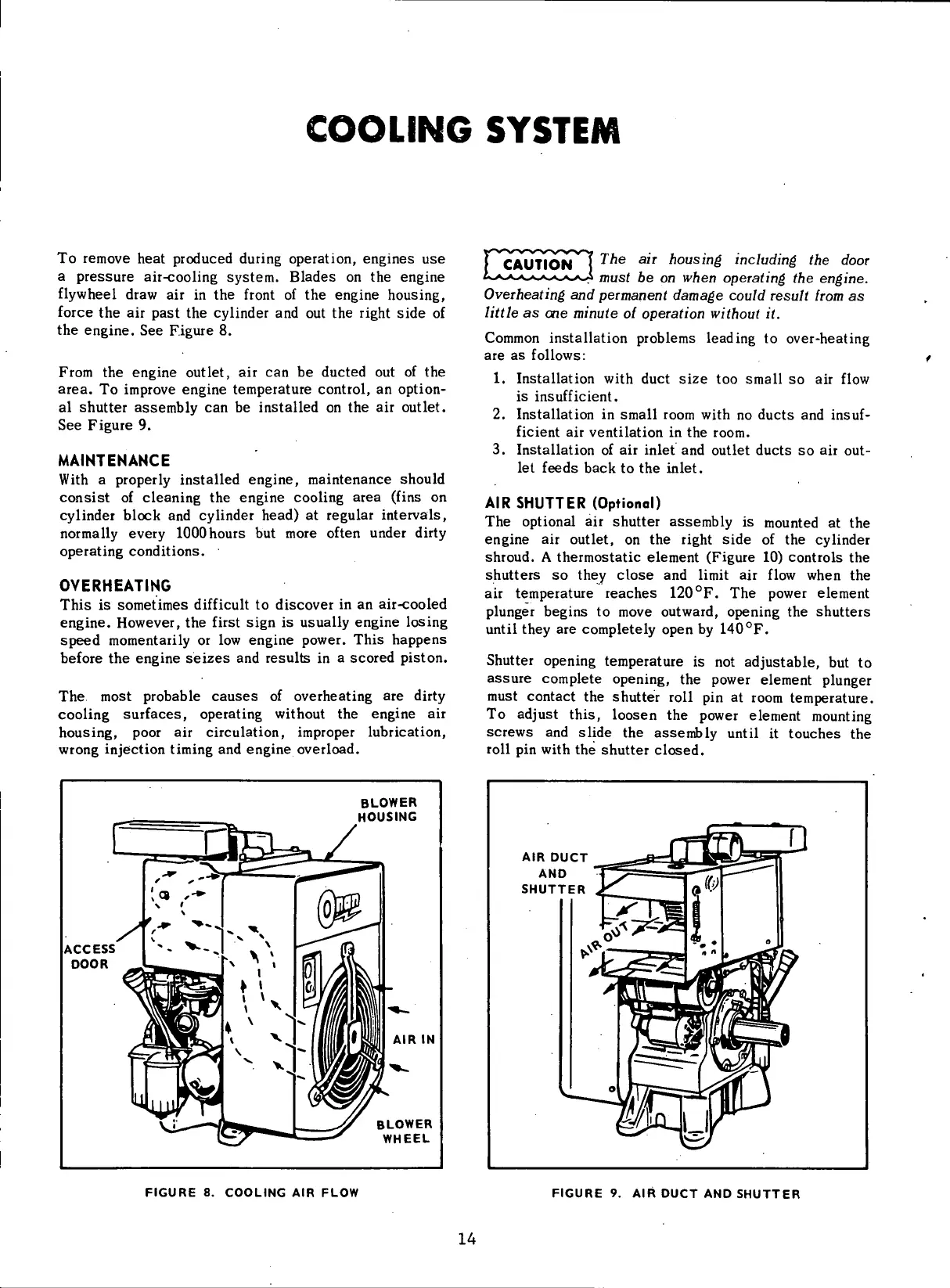

To

remove

heat

produced during operation,

engines

use

a

pressure

air-cooling system. Blades on the engine

flywheel

draw air in the

front

of the engine housing,

force

the air

past

the cylinder and out the

right

side of

the engine. See Figure 8.

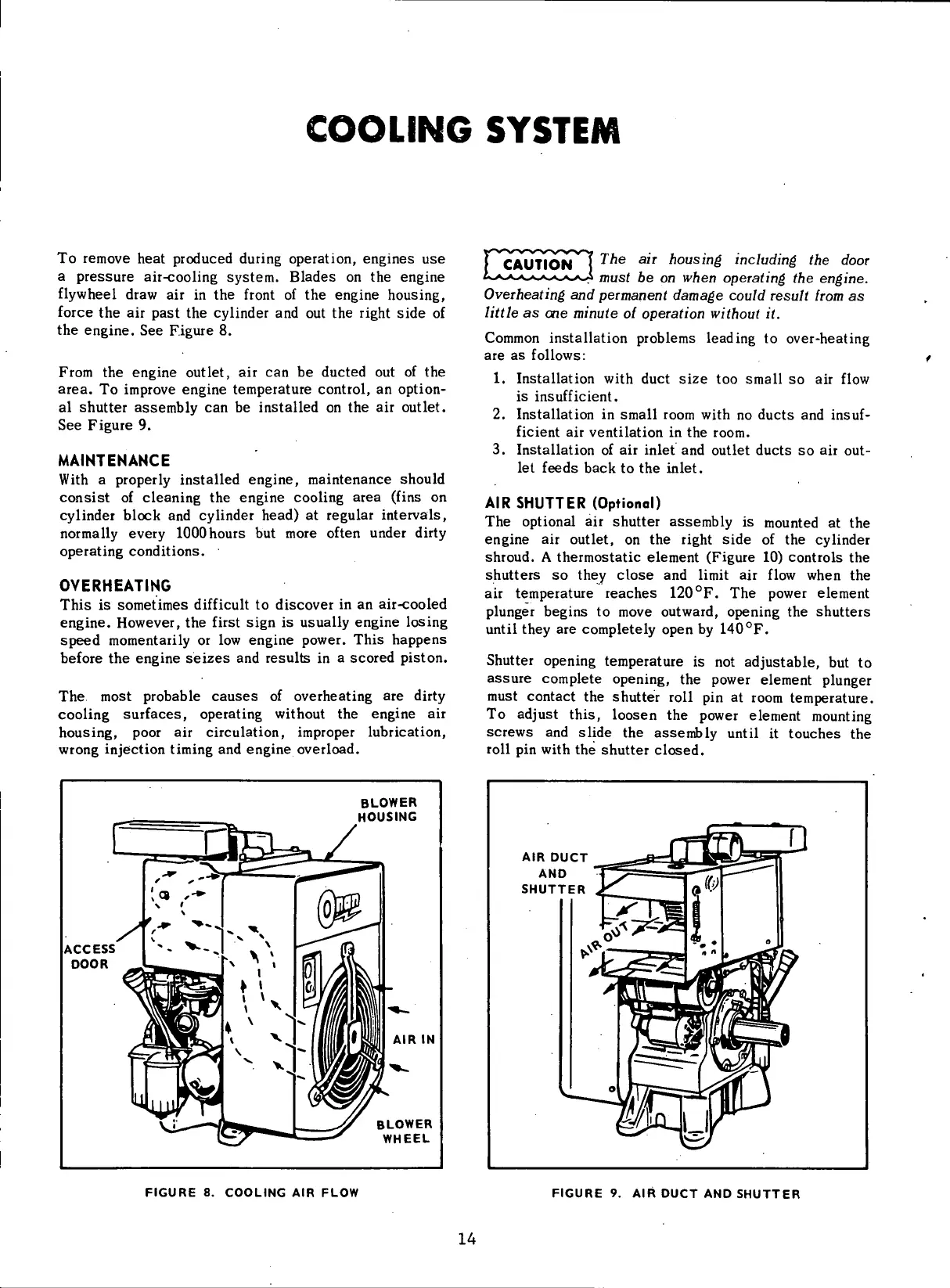

From

the engine outlet, air can be ducted out of the

area.

To improve engine temperature control, an option-

al

shutter assembly can be installed on the air outlet.

See Figure 9.

MAINTENANCE

With

a properly installed engine, maintenance should

consist of cleaning the engine cooling

area

(fins

on

cylinder

block and cylinder

head)

at regular intervals,

normally

every

1000

hours but more often under

dirty

operating conditions.

OVERHEATING

This

is sometimes

difficult

to discover in an air-cooled

engine. However, the

first

sign is usually engine losing

speed

momentarily or low engine power. This

happens

before the engine

seizes

and results in a scored piston.

The most probable

causes

of overheating are

dirty

cooling

surfaces, operating

without

the engine air

housing, poor air circulation, improper lubrication,

wrong

injection

timing

and engine overload.

The

air

housing including

the

door

must

be on

when operating

the

engine.

Overheating

and

permanent damage could result from

as

little

as one

minute

of

operation without

it.

Common

installation problems leading to over-heating

are as

follows:

1.

Installation

with

duct size too small so air

flow

is

insufficient.

2.

Installation in small room

with

no ducts and insuf-

ficient

air

ventilation

in the room.

3. Installation of air

inlet

and outlet ducts so air out-

let

feeds

back to the

inlet.

AIR

SHUTTER

(Optional)

The optional air shutter assembly is mounted at the

engine air outlet, on the

right

side of the cylinder

shroud. A thermostatic element (Figure 10) controls the

shutters so they close and

limit

air

flow

when the

air

temperature

reaches

120

0

F. The power element

plunger begins to move outward, opening the shutters

until

they are completely open by 140

0

F.

Shutter opening temperature is not adjustable, but to

assure

complete opening, the power element plunger

must contact the shutter

roll

pin at room temperature.

To

adjust this, loosen the power element mounting

screws and slide the assembly

until

it

touches

the

roll

pin

with

the shutter closed.

BLOWER

HOUSING

ACCESS

DOOR

AIR

IN

BLOWER

WHEEL

AIR

DUCT

AND

SHUTTER

FIGURE

8.

COOLING

AIR

FLOW

FIGURE

9. AIR

DUCT

AND

SHUTTER

14

Loading...

Loading...