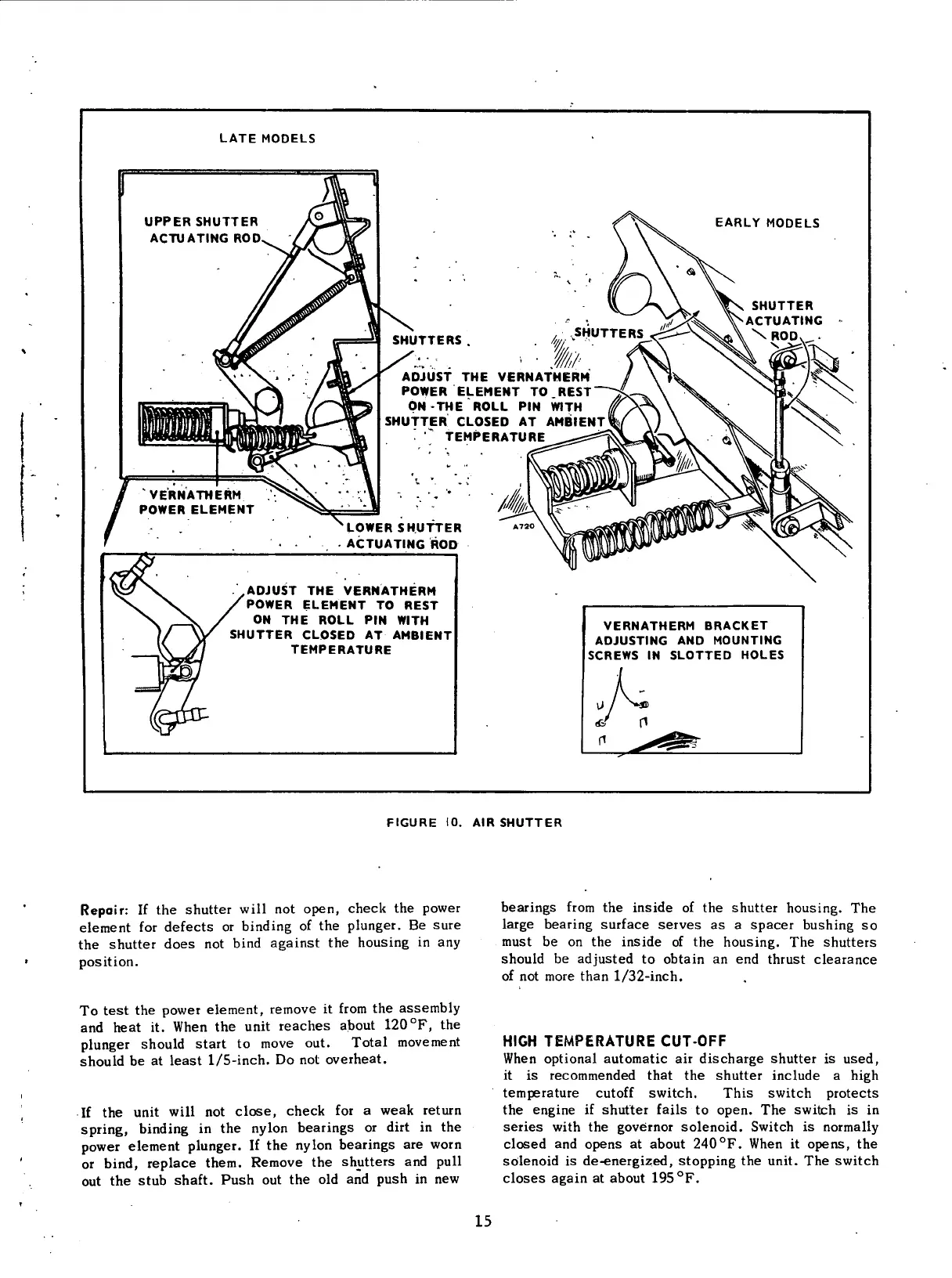

LATE

MODELS

EARLY

MODELS

SHUTTERS.

• •

m

ADJUST

THE

VERNATHERM

POWER

ELEMENT

TO REST

ON THE ROLL PIN

WITH

SHUTTER

CLOSED AT

AMBIENT

" ••"

TEMPERATURE

LOWER

SHUTTER

ACTUATING

ROD

ADJUST

THE

VERNATHERM

POWER

ELEMENT

TO REST

ON THE ROLL PIN

WITH

SHUTTER

CLOSED AT

AMBIENT

TEMPERATURE

VERNATHERM

BRACKET

ADJUSTING AND

MOUNTING

SCREWS

IN

SLOTTED

HOLES

FIGURE

10. AIR

SHUTTER

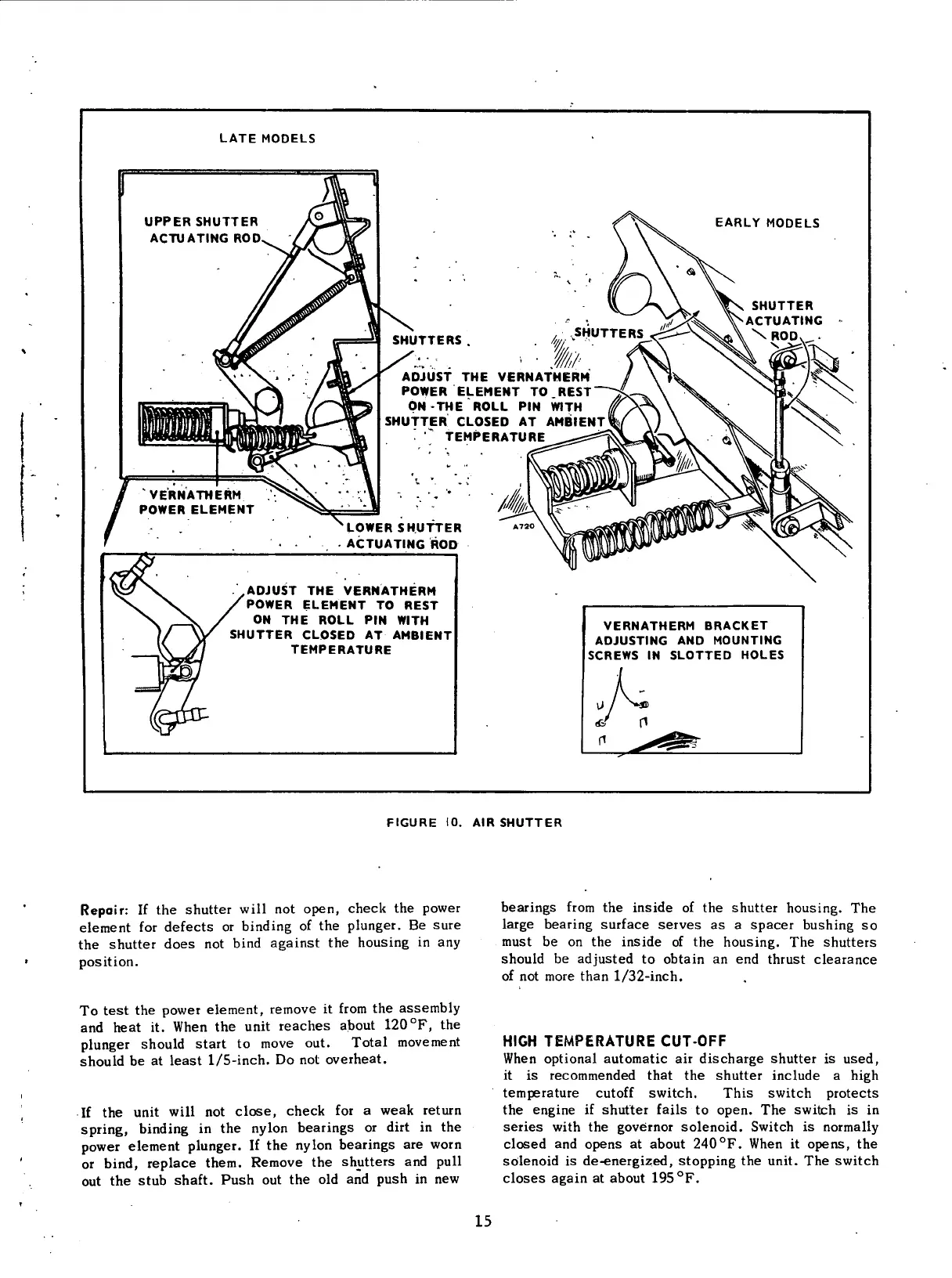

Repair: If the shutter

will

not open, check the power

element for defects or

binding

of the plunger. Be sure

the shutter

does

not

bind

against the housing in any

position.

To

test the power element, remove it

from

the assembly

and

heat it. When the

unit

reaches

about 120

0

F, the

plunger

should start to move out.

Total

movement

should

be at least 1/5-inch. Do not overheat.

If

the

unit

will

not close, check for a weak return

spring,

binding

in the

nylon

bearings or

dirt

in the

power

element plunger. If the

nylon

bearings are

worn

or

bind,

replace them. Remove the shutters and

pull

out

the stub shaft. Push out the old and push in new

bearings

from

the inside of the shutter housing. The

large bearing surface

serves

as a

spacer

bushing so

must be on the inside of the housing. The shutters

should

be adjusted to obtain an end thrust clearance

of

not more than 1/32-inch.

HIGH

TEMPERATURE

CUT-OFF

When

optional

automatic air discharge shutter is used,

it

is recommended that the shutter include a

high

temperature

cutoff

switch.

This

switch

protects

the engine if shutter

fails

to open. The

switch

is in

series

with

the governor solenoid.

Switch

is

normally

closed

and

opens

at about 240

0

F. When it opens, the

solenoid

is de-energized, stopping the

unit.

The

switch

closes again at about 195

0

F.

15

Loading...

Loading...