INSTALLATION

GENERAL

Plan the installation carefully to insure maximum operating

efficiency.

Use this manual as a general guide. Recom-

mendations in this manual are

based

on extensive

tests

under favorable operating conditions. Abide by pertinent

local

codes

regulating installation and operation of intemal

combustion

engines.

LOCATION

Engine location is determined

chiefly

by the intended

appUcation.

Provide

adequate

access

for service and repair.

Protect the engine

from

adverse

weather. Consider the.

location

of related

systems,

such as

fuel,

exhaust and

ventilation.

MOUNTING

Secure

the engine to a

rigid,

level

foundation. Foundations

must be sturdy enough to withstand distortion and retain

alignment

with

complementary equipment.

If

necessaiy

to exceed 23°

tilt

angle, consult the factory.

Compensate

for any

tilt

when checking

crankcase

oil.

VENTILATION

Ventilation

is

needed

to cool the engine and support com-

bustion.

Avoid

recirculation of

ventilating

air.

See

Specifi-

cations for air

flow

requirements and vent

sizes.

Locate vents so air

flow

from

the

inlet

to the outlet

will

pass

over the engine. The outlet should be

slightly

higher

than the

inlet.

An

optional air shutter may be used in the outlet duct to

control

engine temperature by regulating air

flow.

Air

shutters also prevent back

flow

of

cold

air during engine

shut-down.

When

ventiducts are used between the engine and outlet

vent, use a

canvas

section to restrict

vibration.

EXHAUST

Pipe exhaust gas outside any enclosure - Exhaust Gas is

Poisonous. Exhaust pipes must not terminate

near

inlet

vents.

Avoid

sharp

bends

by

installing

sweeping, large

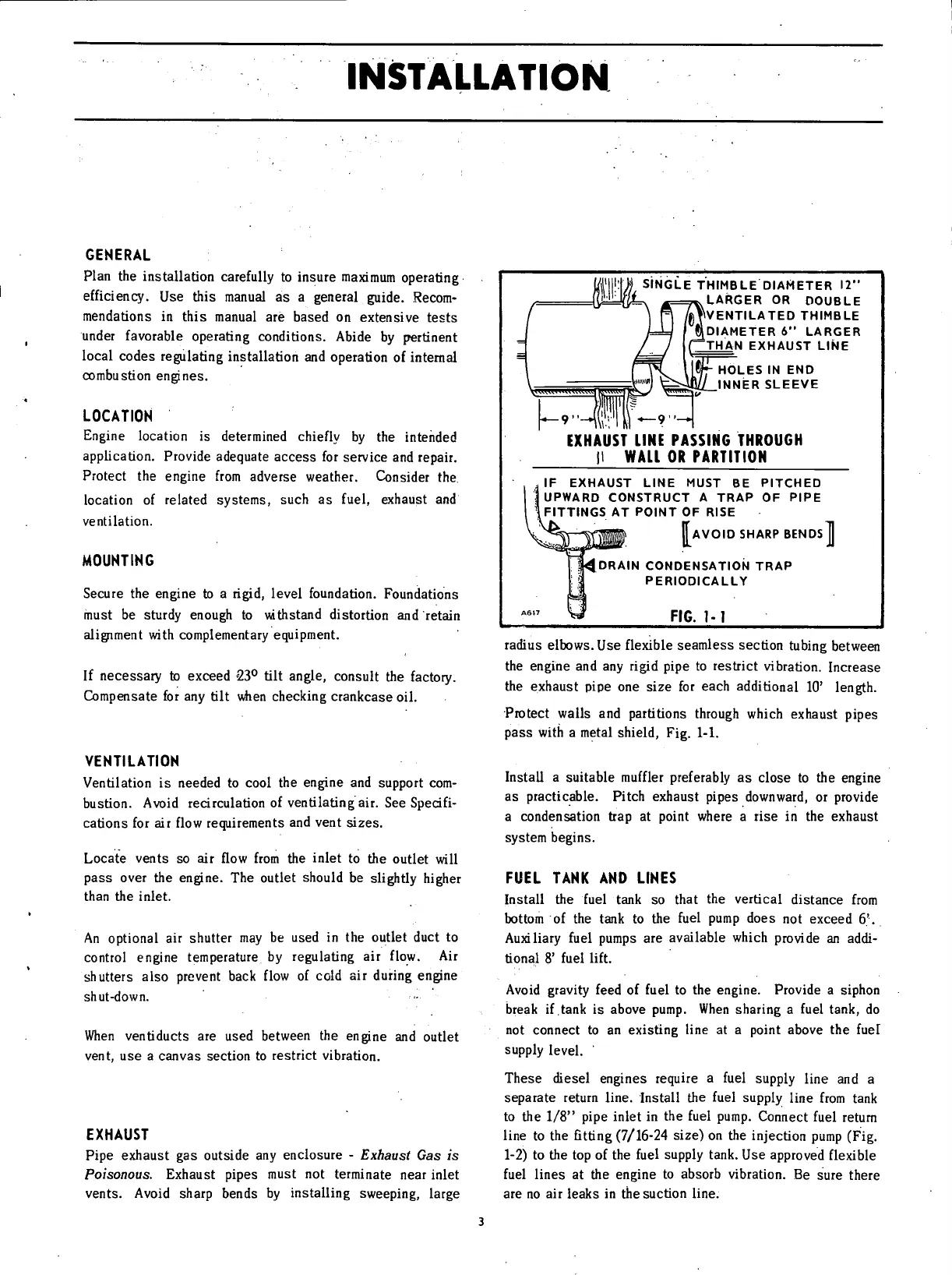

SINGLE

THIMBLE

DIAMETER

12"

LARGER

OR DOUBLE

VENTILATED

THIMBLE

DIAMETER

6"

LARGER

THAN

EXHAUST

LINE

HOLES

IN

END

INNER

SLEEVE

EXHAUST

LINE

PASSING

THROUGH

[I

WALL

OR

PARTITION

IF

EXHAUST

LINE

MUST

BE

PITCHED

UPWARD

CONSTRUCT

A

TRAP

OF

PIPE

FITTINGS

AT

POINT

OF

RISE

AVOID

SHARP

BENDS

1

^

DRAIN

CONDENSATION

TRAP

PERIODICALLY

FIG.

1-1

radius

elbows.

Use

flexible

seamless

section tubing between

the engine and any

rigid

pipe to restrict

vibration.

Increase

the exhaust pipe one size for

each

additional 10' length.

Protect walls and partitions through

which

exhaust pipes

pass

with

a metal shield, Fig. 1-1.

Install

a suitable

muffler

preferably as close to the engine

as practicable. Pitch exhaust pipes downward, or provide

a condensation trap at point where a rise in the exhaust

system begins.

FUEL

TANK

AND

LINES

Install

the

fuel

tank so that the vertical distance

from

bottom

of the tank to the

fuel

pump

does

not exceed 6'.

Auxiliary

fuel

pumps are available

which

provide an addi-

tional

8'

fuel

lift.

Avoid

gravity feed of

fuel

to the engine. Provide a siphon

break if tank is above pump. When sharing a

fuel

tank, do

not

connect to an existing

line

at a point above the

fuel

supply

level.

These

diesel

engines

require a

fuel

supply

line

and a

separate

return

line.

Install

the

fuel

supply

line

from

tank

to

the 1/8" pipe

inlet

in the

fuel

pump. Connect

fuel

retum

line

to the

fitting

(7/16-24 size) on the

injection

pump (Fig.

1-2) to the top of the

fuel

supply

tank.

Use approved

flexible

fuel

lines at the engine to

absorb

vibration.

Be

sure

there

are no air leaks in the

suction

line.

Loading...

Loading...