OPERATION

CRANKCASE

OIL

The oil capacity is 3 U.S. quarts (plus 1/2 quart for oil

filter). Be sure the engine is level when filling. Fill to

F (full) mark on indicator. Use a good,heavy duty deter-

gent oil classified by American Petroleum Institute for

service DS (Diesel Severe) also known as Series 3 oil.

Use the proper SAE number oil for the expected tem-

perature conditions. Do not mix brands nor grades. If

service DS oil is not available in 5W-20 viscosity, use

service DM and change oil more frequently. Alv/ays

reinstall oil indicator air tight.

IF

TEMPERATURE

IS

USE

Above

30

o

F

0

o

F to

30

o

F

Below

0

o

F

SAE 30

SAE 10W or

5W-20

SAE

5W-20

Do not mix

brands

or

grades.

Refer

to

Maintenance

Section

for

recommended

oil

changes.

OIL

BATH AIR

CLEANER

(Optional)

Use the

same

grade

of oil in the air

cleaner

as is

used

in the

crankcase.

The

proper

level

is

marked

on the air

cleaner.

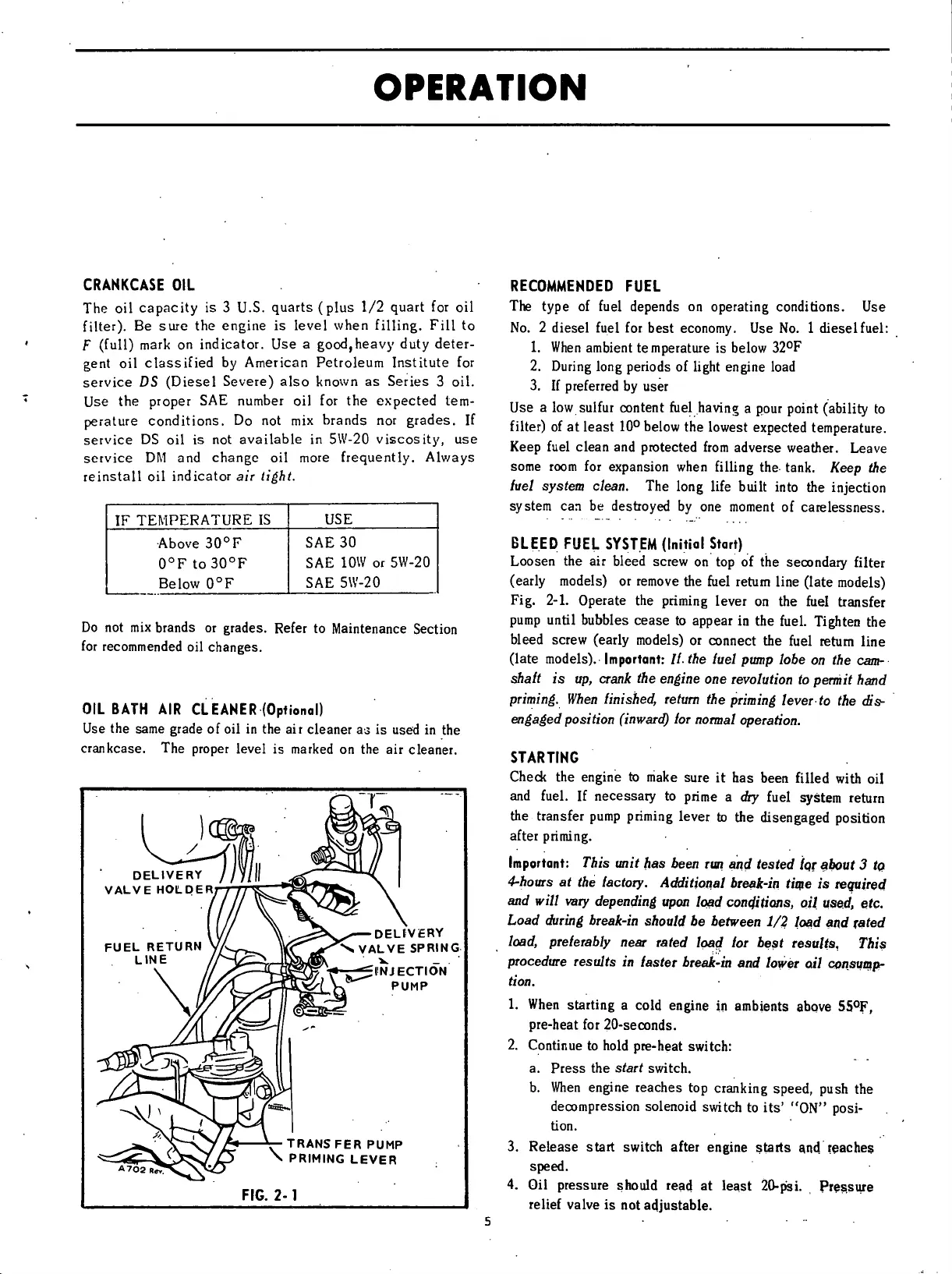

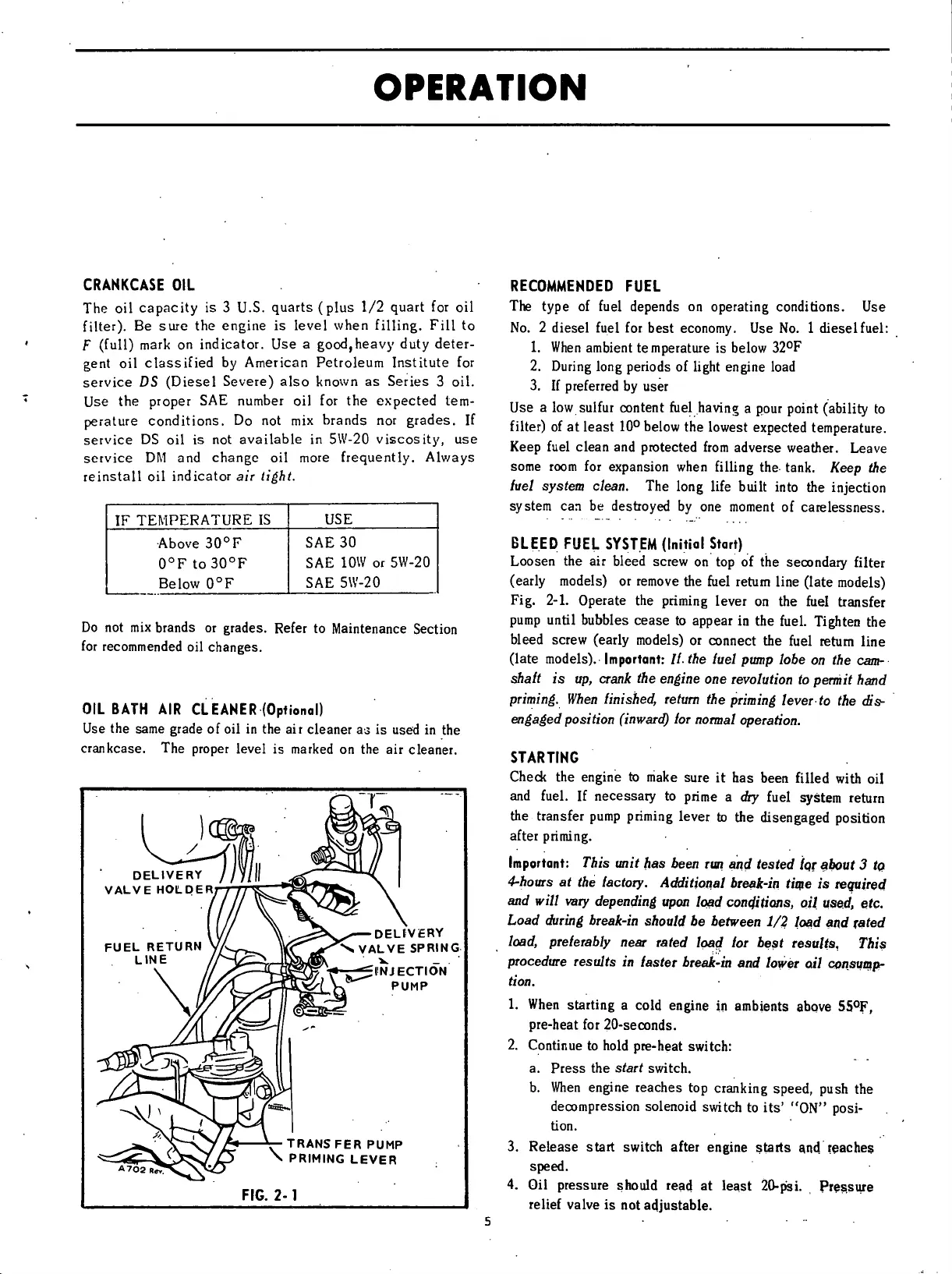

DEUVERY

'WALVE SPRING

INJECTION

PUMP

TRANSFER

PUMP

N PRIMING

LEVER

FIG.

2-1

RECOMMENDED

FUEL

The

type

of fuel

depends

on

operating

conditions.

Use

No. 2

diesel

fuel for

best

economy.

Use No. 1

diesel

fuel:

1.

When

ambient

temperature

is

below

32

0

F

2. During

long

periods

of light

engine

load

3. If

preferred

by

user

Use a low

sulfur

content

fuel

having

a

pour

point

(ability to

filter)

of at

least

10°

below

the

lowest

expected

temperature.

Keep

fuel

clean

and

protected

from

adverse

weather.

Leave

some

room

for

expansion

when

filling

the

tank.

Keep

the

tuel

system

clean.

The

long

life

built

into

the

injection

system

can be

destroyed

by one

moment

of

carelessness.

BLEED

FUEL SYSTEM

(Initial

Start)

Loosen the air bleed screw on top of the secondary filter

(early models) or

remove

the fuel

return

line (late models)

Fig. 2-1. Operate the priming lever on the fuel transfer

pump until bubbles cease to

appear

in the fuel. Tighten the

bleed screw (early models) or connect the fuel retum line

(late models).

Important:

If.the Iuel

pump

lobe on the cam-

shaft is up, crank the engine one revolution to permit

hand

priming.

When

finished, retum the

priming

lever to the dis-

engaged

position

(inward)

lor

normal operation.

STARTING

Check

the

engine

to

make

sure

it has

been

filled

with oil

and fuel. If

necessary

to

prime

a dry fuel

system

return

the

transfer

pump

priming

lever

to the

disengaged

position

after

priming.

Important: This unit has been run and tested fqr about 3 te

4-hours at the factory. Additional

break-in

time is required

and will vary depending

upon

load

concfitions,

oil used, etc.

Load

during

break-in should be between 1/2 load and rated

load, preferably near rated load for best results, This

procedure results in faster

break-in

and lower ail consump-

tion.

1.

When

starting

a cold

engine

in

ambients

above

5S

0

F,

pre-heat

for

20-seconds.

2.

Continue

to hold

pre-heat

switch:

a.

Press

the sfarf

switch.

b.

When

engine

reaches

top

cranking

speed,

push

the

decompression

solenoid

switch

to its' "ON"

posi-

tion.

3.

Release

start

switch

after

engine

starts

and

teaches

speed.

4. Oil

pressure

should

read

at

least

20-psi.

Pressure

relief

valve

is not

adjustable.

Loading...

Loading...